We take a closer look into acrylic vacuum chambers, what they are used for, the advantages and disadvantages of using a clear acrylic vac chambers for vacuum applications, what to look for when buying one, and where to purchase one.

By the end of this article, you will fully understand acrylic vacuum chambers what these can be used for and how these can be of benefit to you.

What is an acrylic vacuum chamber?

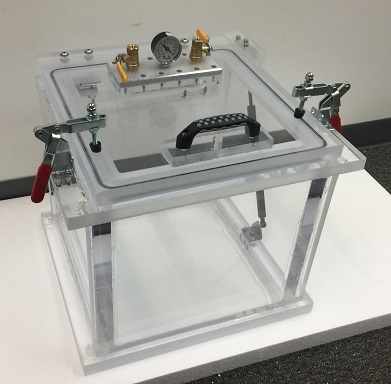

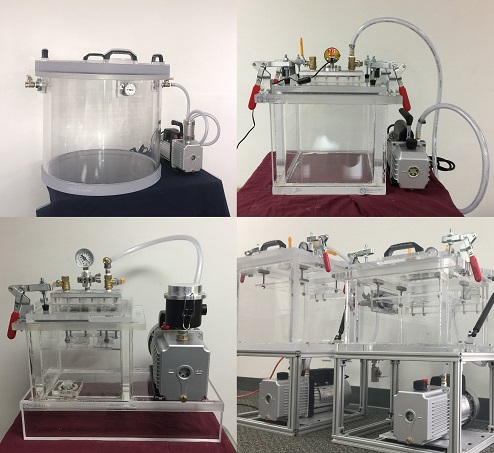

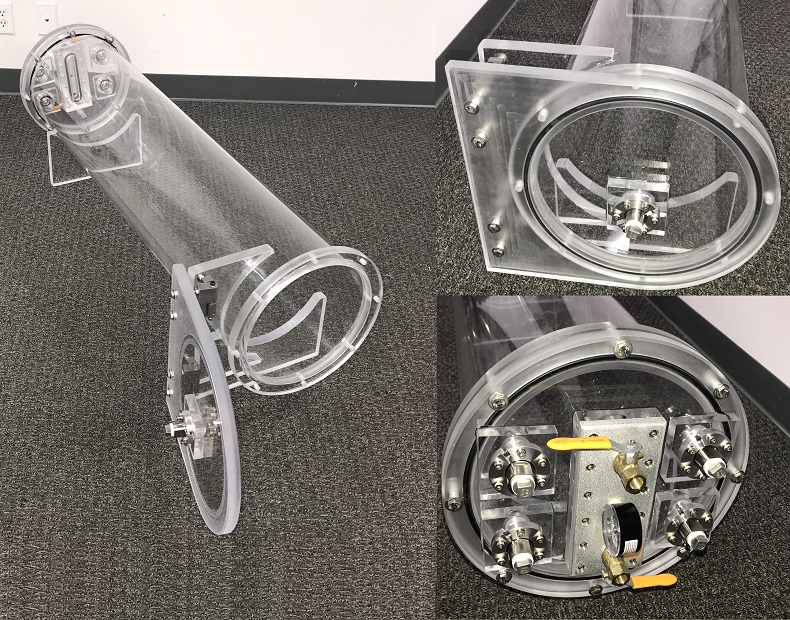

An acrylic vacuum chamber is, as the name implies, a vacuum chamber that is built from the acrylic polymer. The acrylic panels are specialty machined, prepared, and glued (or welded) in such a way to create an air tight seal between the walls. There is a lot of know-how and engineering that goes into the process of fabricating a quality chamber. In the end, the final product can be used as a vacuum chamber. Acrylic vacuum chambers are preferable over its metallic counterparts due to the fact that acrylic is fully transparent, cost effective, and versatile meaning that it can be used in a plethora of vacuum applications.

Advantages of using an Acrylic Vacuum Chamber

Clear view of your vacuum chamberAcrylic is also known as Plexiglas or Poly(methyl methacrylate). The main reason to use an acrylic chamber is that it allows for full visibility of the interior during operations from all angles. Perhaps you need to see your sample from all sides, a chamber made from acrylic will allow you that. In addition to visibility, acrylic chambers blend in much better into the environment making them look like they are not taking up too much shelf space. Acrylic is much less clunky than steel or aluminum chambers and much more stylish. Acrylic vacuum chambers look a whole lot cleaner than steel or aluminum.

Robust Acrylic Chamber

An advantage of acrylic is that acrylic resembles most of the optical properties of glass. However, acrylic is much more useful than glass because it is 10 - 25 times more impact resistant than glass. Acrylic is less dense than glass making it twice as light. Acrylic will not yellow or blemish over time and will stay crystal clear for years to come. Acrylic transmits up to 92% of all visible light; this makes it one of the clearest materials known to men (glass transmits about 85% of all light). Acrylic is fairly resistant to chemical attacks. Acrylic is robust and will stand up to the elements much longer than any other plastics.

Flexible and Organic

An acrylic vacuum chamber is flexible and will, over time, conform to the assembly it is connected to. After some time, you will notice that your acrylic chamber is working better with your system. This is due to the fact that the acrylic vacuum chamber has molded around your system and now seals better.

Cheap Vacuum Chamber

Finally, vacuum chambers made from acrylic are inexpensive when compared to Steel or Aluminum chambers. Metallic chambers have their place in higher vacuum environments, we will talk more about this later. There are countless examples where acrylic is the better choice due to the fact that a low vacuum is required and a reasonably priced option is sought after.

Highly Customizable

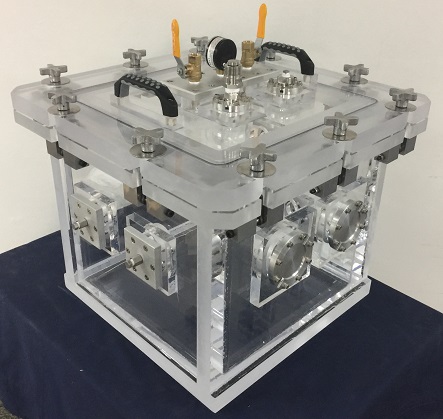

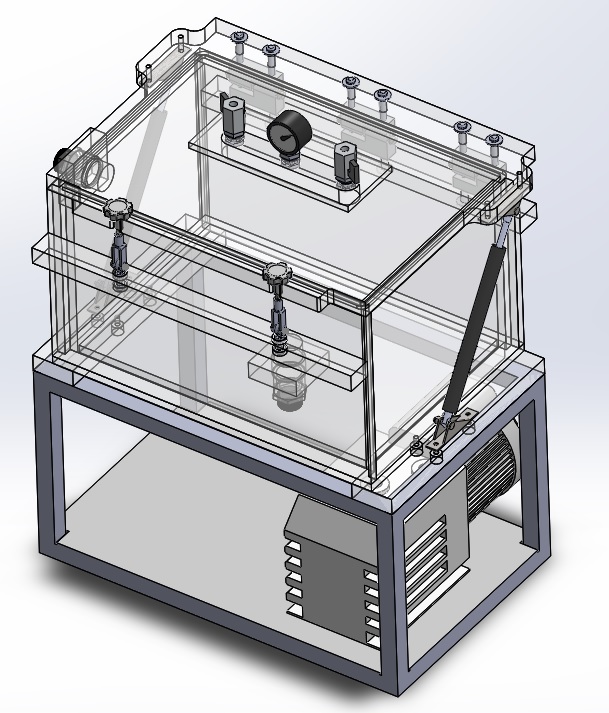

Due to acrylic being an easily machinable and routable polymer, acrylic vacuum chambers are highly customizable. This means that it is relatively easy to add various vacuum feedthroughs such as thermocouple, liquid, power, data, motion and other to the acrylic vacuum chamber. In addition, various QF, KF, and NW vacuum components and vacuum valves can be added with ease. As a result, and acrylic vacuum chamber can become a powerful tool because a wide range of applications and experiments can now be conducted after all the aforementioned peripherals have been added.

If you are interested to find out more about customizing an acrylic vacuum chamber, please check out our article on Customizing Your Acrylic Vacuum Chamber

Easily Repairable

In the unlikely or unfortunate event where an acrylic vacuum chamber gets damaged, it can be easily repaired if you have the right epoxy/glue available. Heck, sometimes superglue will work as well. As opposed to metallic vacuum chambers, where you would need some welding skills to repair a leak or crack, an acrylic vacuum chamber can be glued back into place if its dropped or damaged. Additionally, due to transparent walls of an acrylic chamber, it is also fairly easy to locate and discover the damage or leak.

Low Maintenance

An acrylic vacuum chamber is very easily to maintain and operate and will not require much maintenance other than periodic O-Ring Replacement. How often you need to replace your O-Ring depends on how often you use your vacuum chamber. The end users of our vacuum chambers generally replace the O-Ring once every 1 to 2 years. The valves, vacuum gauge, clamps, hinges, and other vacuum chamber components usually have a lifetime which is equal or grater than the lifetime of the vacuum chamber which means that these will outlast a vacuum chamber.

Wide Range of Vacuum Applications

Our vacuum chambers are rated to 0.075 Torr (75 micron) absolute pressure. This means that you can achieve a 99.99% vacuum. This vacuum range opens doors for a plethora of applications, experiments, and processes that can be conducted utilizing an acrylic vacuum chamber.

To summarize, the advantages of using Acrylic Vacuum Chambers are:

Can acrylic vacuum chambers be pressurized?

The walls of our vacuum chambers are designed to withstand full vacuum (-14.7 psi) and therefore can withstand a positive pressure of up 14.7psi. This can be accomplished by adding clamps to the lid to keep the O-Ring compressed while pressure is applied to the chamber. Additionally, a pressure relief valve must be installed in order to prevent any accidental over-pressurization of the chamber beyond its designed pressure. Our acrylic vacuum chambers can be easily converted to vacuum and pressure chambers with the aforementioned additional components whereas the vacuum chamber can now be operated from -14.7psi to +5 psi, +10 psi, or 15 psi.

Are acrylic vacuum chambers safe?

The acrylic vacuum chambers manufactured by us (Sanatron) are robustly designed and quality manufactured. Our chambers are designed to withstand many times more the force of vacuum applied to the walls (even at full vacuum of 30 inHg) and are safe to be operated at any vacuum level you are able to reach with your vacuum pump. In addition, the wall thickness of each of our chambers has been carefully calculated and experimentally confirmed to have the ability to undergo hundred of thousands of cycles between vacuum and ambient pressure.

The useful life of an acrylic vacuum chamber

With proper care, an acrylic vacuum chamber can be expected to last for at least 10 years; in many cases much longer. There are no moving parts on this type of vacuum chamber, hence there is no wear and tear on the acrylic. Conversely, our chambers are robustly designed and wall thickness carefully specified so that the shear stress applied onto any point of our chamber does not exceed 7 MPa. This design allows for 1 Million Vacuum Cycles – that is our acrylic vacuum chamber can be successfully cycled from ambient to full vacuum 1 Million Times.

The only component that needs to be maintained is the O-Ring which can after some time wear out. Fortunately, the O-Rings are easy to replace and very inexpensive to order.

Disadvantages of using a Chamber made from Acrylic

Using Plexiglas vacuum chambers does have its disadvantages as well. Perhaps you have heard it say that there is no such thing as the perfect material; you have to make choices by artfully balancing the cost, strength, material properties, availability, machinability, weldability, and other pertinent requirements.

Acrylic is more permeable than metal

The first disadvantage of acrylic is its permeability and outgassing. Permeable materials diffuse air more quickly through the walls which means that an acrylic vacuum chamber will be at a persistent vacuum loss over time. Additionally, acrylic will outgas molecules from its wall at a rate that is 2 to 3 orders of magnitude higher than steel. This also prevents acrylic chambers from being the appropriate choice in high vacuum applications.

Acrylic is operates in narrow temperature range

Acrylic has a melting point of 320 °F (160 °C) and a glass transition temperature of 221 °F (105 °C). This fact eliminates acrylic as a suitable material for high temperature applications. In fact, acrylic vacuum chambers should not be heated beyond 105 °F (40 °C). Likewise acrylic becomes incredibly brittle at temperatures below -112°F (-80 °C), disqualifying it for cryogenic vacuum applications.

Chemically Susceptible

Acrylic is not chemically resistant to a some of materials used in labs such as Alcohols, Acetones, Hydrogen Peroxide, Thinners, Benzenes, Lactates, and other. This means that constant exposure these compounds will blemish, even damage the acrylic walls of the chamber.

Prone to electro-static buildup

Acrylic Chambers may cause static electricity if "rubbed the wrong way", which may potentially damage electronics, ignite volatile gasses, or create electrostatic noise. Acrylic gets zero shielding from electromagnetic interference but that may only pose a problem if there are strong electric fields in the vicinity.

Acrylic is strong but brittle

Another disadvantage of acrylic chambers is that acrylic is brittle and that it will crack under concentrated stresses. This means that it is not recommended to thread acrylic because the force put onto the acrylic from the screw threads will develop cracks and crazes in the acrylic material. Finally, due to its material properties, acrylic vacuum chambers require thick walls even at small vacuum volumes in order to withstand the stress of ambient atmospheric pressure. This results in an exponential wall thickness requirement as the vacuum chamber volume increases; hence, acrylic vacuum chambers may not be ideal materials in large vacuum applications.

Acrylic can be scratched easily

The walls of the acrylic vacuum chamber can be scratched easily with a sharp or coarse object. Even dragging the chamber across the floor will create visible scratches on the bottom wall. Depending on the depth of the scratch, these may not be easily reparable. Though, not something that would compromise the structural integrity of the chamber, these scratches can become a cosmetic nuance.

To summarize, the disadvantages of using Acrylic Vacuum Chambers are:

What to look for in a Plastic Vacuum Chamber

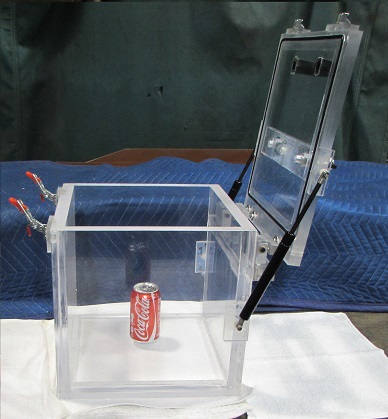

Side view of our Transparent Vacuum Chamber with a Coca Cola Can in comparison. You can buy it here

Side view of our Transparent Vacuum Chamber with a Coca Cola Can in comparison. You can buy it here

Below, are some of the things that you have to look for before you can make an educated decision about what kind of vacuum chamber to get.

Vacuum RatingThe first thing that you will need to look into is the vacuum rating. After all, you are getting a vacuum chamber aren`t you? What vacuum level is the chamber rated to? Most acrylic vac chambers are an excellent solution for degassing compounds and epoxies. A good Acrylic Vacuum Chamber can reach down to a vacuum level of under 1 Torr; anything below 1 Torr is considered superb.

Internal Chamber DimensionsThe internal dimensions as opposed to the external dimensions of the chamber should also be considered – you are, after all buying the internal vacuum space of that chamber.

Vacuum Gauge, Valve, and ComponentsLook into what else is included with the deal; is a vacuum gauge included or sold separately, what about valves? Are they included or sold separately? What about shipping? Is this an industrial vac chamber robust to withstand constant use or is it one of these low use types of clear vacuum chambers? Is the listing straight forward or not as descriptive?

ServiceAre you being served properly? Is the staff helpful and competent? How do you feel about the company? Do you have other concerns or wishes that you need to have addressed? Is your supplier willing to add additional items to your order? Can they customize your chamber? Are they able to? What about delivery, can they deliver on spec, on time, and on budget?

Acrylic Vacuum Chambers for Sale

If you have a need for a clear acrylic vacuum chamber, you have come to the right place. We carry a wide selection of acrylic vacuum chambers for sale at a value and price that is truly remarkable! There are 38 different chamber designs and sizes available for you to choose from. All of our acrylic vacuum chambers come with a vacuum gauge, a vacuum valve, and a release valve. Do you need a custom vacuum chamber? We can do that for you as well!

The inside dimensions range from 8 inches to 20 inches; we have both cubic and cylindrical designs that come with several other options as well. Our standard models have a vacuum rating of 0.5 Torr. Depending on which option you choose, you will have a choice between a fully removable lid (top load model), hinged side door (side load model), a gas spring supported lid (top load model), a door handle or two, and pull toggle clamps.

Where else to get a Transparent Vacuum Chamber

We are going to review several other places that offer a see through vacuum chamber. It all depends on what you are looking for. What are your priorities when it comes to your purchase? Are you just looking to pull a low vacuum? Are you looking to get the cheapest transparent chamber possible? Do you want durability and robustness? Is this a light use or a more heavy industrial use?

What we are going to do is provide you with several places where you can purchase your chamber online. Below is a table summary of several places that sell acrylic vacuum chambers. We understand that we are now promoting our competition but we do this because we are confident that you are going to get the best value, highest quality, most bang for the buck and most features from our chambers. However, you are free to shop around, so here they come:

1. Our Acrylic Vacuum Chambers

We were not kidding when we said that our chambers are the most value for the least buck.

2. Abbess Instruments

Abbess Instruments is another acrylic vacuum chamber supplier, their chambers will pump down to less than 1 Torr at a price that is somewhat a little steep.

3. Cleatech

Cleatech vac chambers come at a reasonable price; however, they will pump down as low and are only rated to 29.8in Hg or about 3 Torr.

4. Terra universal

Their product comes at a somewhat expensive price but their chambers will go down to about 29.9 in Hg or less than 1 Torr.

5. Plas Labs

Plas Labs vacuum chambers are fairly cheap but they will only pump down to about 25 in Hg or somewhere about 120 Torr.

6. Best value Vacs

Best value vacs is the source of cheap economy vacuum chambers including clear acrylic vac chamber. But, the cost savings come at a cost of not as high vacuum levels to about 29.5 in Hg which equals to about 11 Torr.

7. Ideal vacuum Products

The vacuum chambers coming from this vendor will go down to about 0.001 Torr at a very reasonable price.

8. LACO Technologies

Laco acrylic chambers are rated to about 29.9 in Hg or 0.1 Torr and come at a competitive price.

9. Amazon or Ebay

You may also want to search on amazon or ebay for acrylic chambers as well.

10. Thomas Net

You can also shop or call around on Thomas Net to see if more places sell plastic vacuum chambers

Do you know of any other places that sell acrylic chambers? Contact us to have them added to this list at info@sanatron.com

In Conclusion

We hope that this article has clarified some things when it comes to Acrylic Vacuum Chambers and if you have any more questions with regards to what we have talked about please Contact Us with your questions and feedback.

Similar Items

Our clients prefer to work with us because we are Experts in Custom Fabrication (especially Polymer Fabrication). You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers