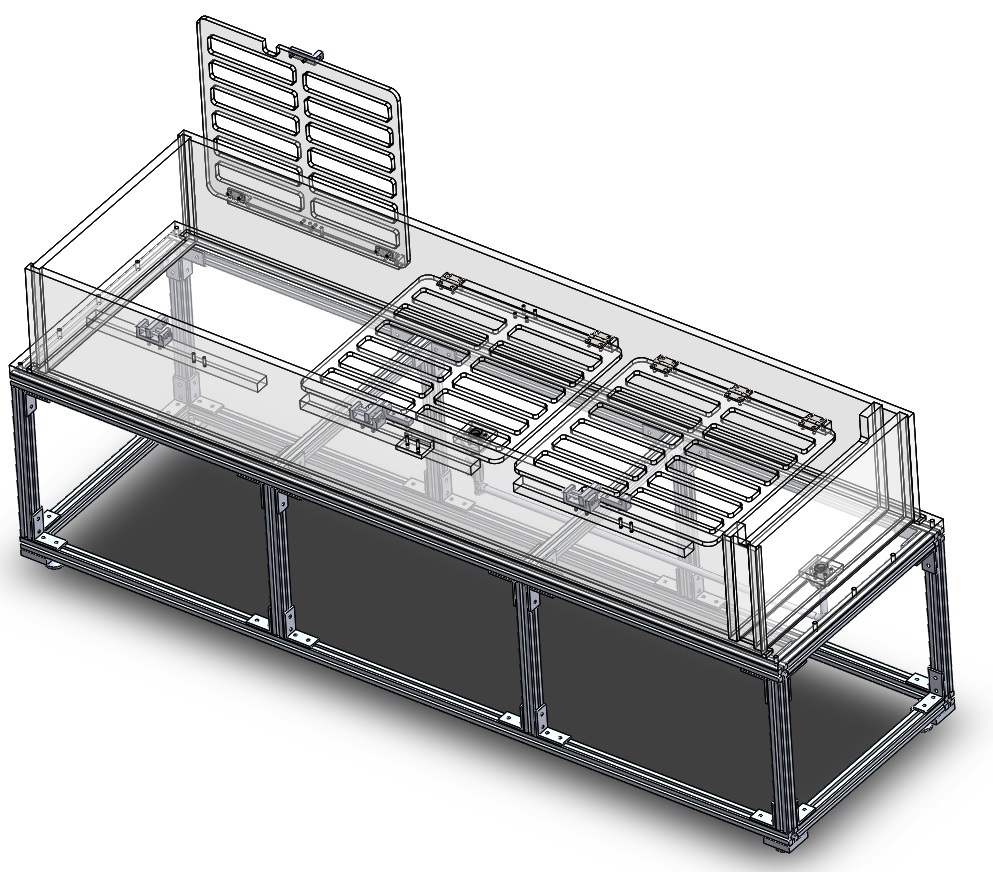

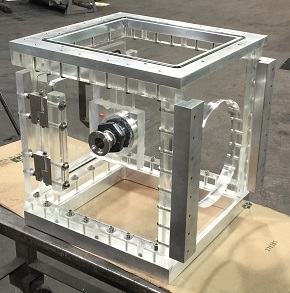

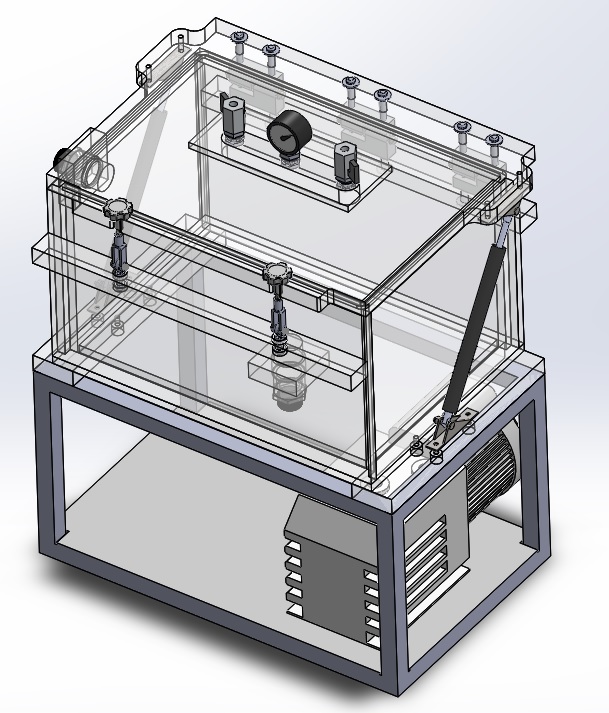

F2096 Submersion Leak Test Tank, Table, and Pressurization System 55 Wide 20 Deep 12 High

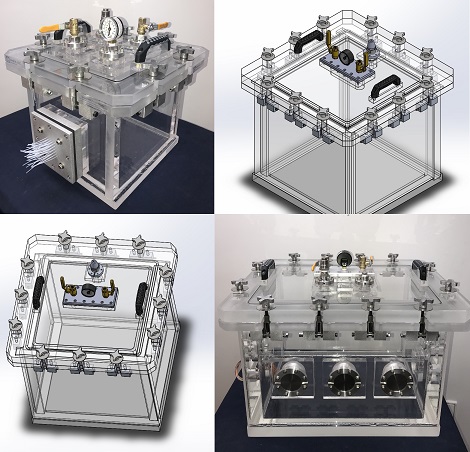

Additional Vacuum Chamber Images

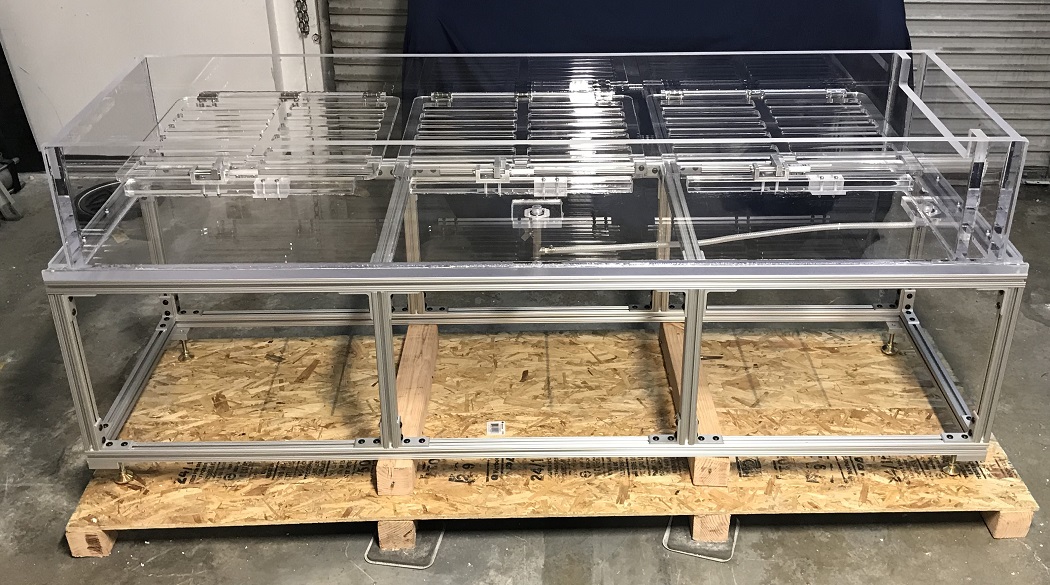

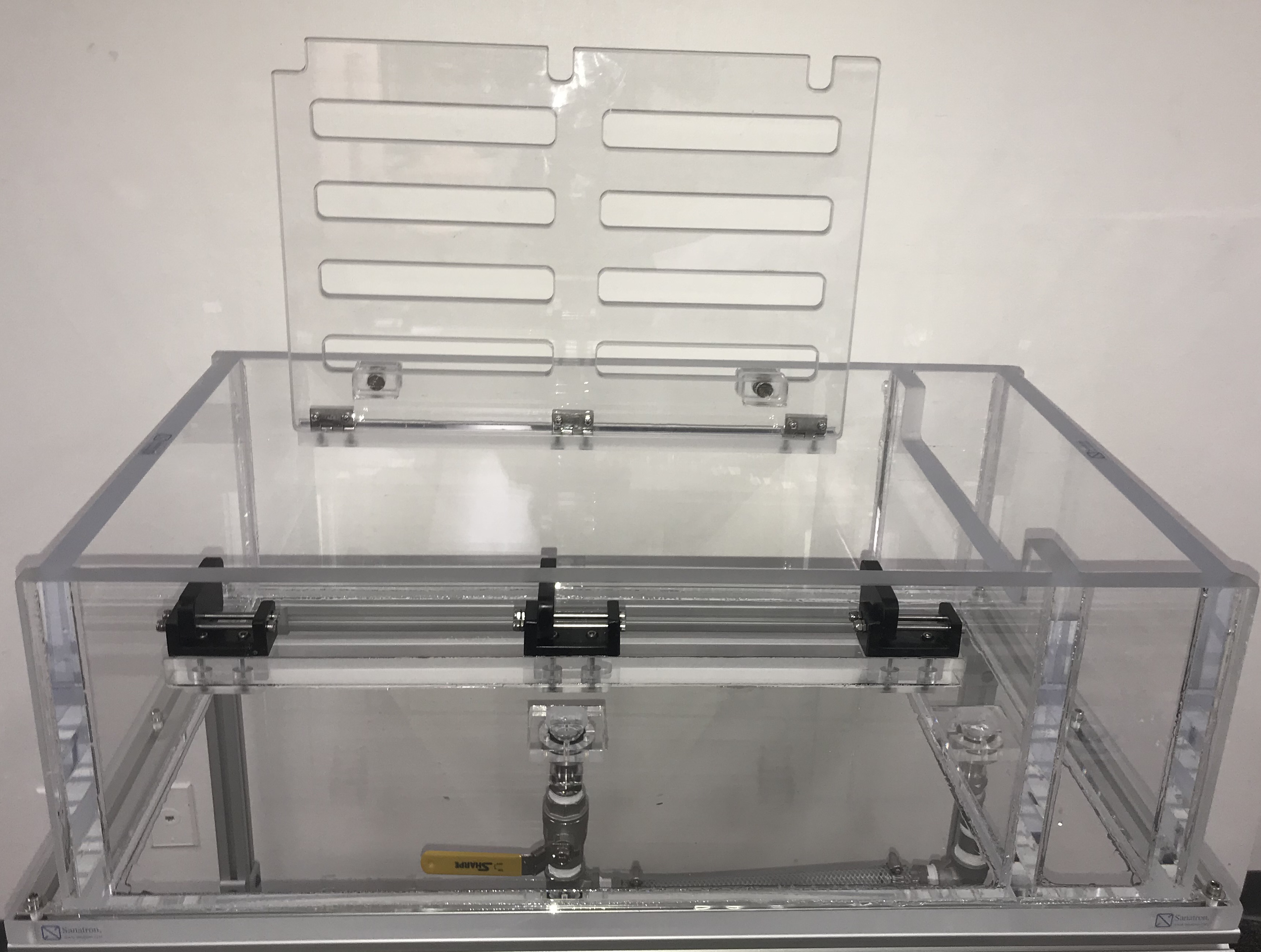

Please take a look at additional images of our internal pressurization leak testing tank. Fortunately, this tank is customizable and can be customized to your requirements. Feel free to contact us if you have any questions.

Product Specifications

Features

Description

This is an internal pressurization bubble testing system that is designed specifically to enable you to properly, comprehensibly, and effectively perform the package integrity test; including but not limited to the ASTM F2096. This package integrity test is fully setup and ready to go, there is no assembly or additional work required.

This system comes with three main components: 1. Quality Built, Clear Acrylic Bubble Leak Testing Tank: The inside dimensions of the acrylic tank are 55 inch Wide by 20 inch Deep by 12 inch High at 9 inch water height. The acrylic tank also comes with one hinged and lockable lid. This lid is used to keep the inflated specimen submersed during the leak test. 2. Table structure: The Table is 26 inch Wide by 15 inch deep by 24 inch high. Depending on your request, it comes with either Lockable Casters or Adjustable Feet. The table is made from 8020 Inc. Aluminum Industrial Erector Sets. 3. A Pressurization System: for Bubble Leak Testing, including the test probe and connection components. Lastly, this system includes the Pressurization System that is also assembled. The pressurization system consists of a Precision Flow Control Valve, Magnehelic Differential Pressure Gage, and a Pitot-Style Static Probe that can be inserted into your test specimen.

Finally, this internal pressurization system can be used for any type of pressurized leak test of specimen such as IV bags, heat sealed bags, rigid containers, even machined components. This system is especially popular among items that can be easily connected to a pressurized line such as plastic tanks. The main advantage of this internal pressurization leak testing system is that the leak can be detected and located via the emission of bubbles. Another advantage is that this leak testing system can also test for connection adapters quality ? meaning that the specimen connections can also be a source of leakage, this system will detect this type of defect through the emission of bubbles at the connection.

Did you know that we carry a many more products?

We make Robustly Designed and Quality Engineered Systems. You should check out some of our other items we carry; click on the links below.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.