Pressure Decay Leak Tester NANO, 3 Test Channels

Product Specifications

Features

Description

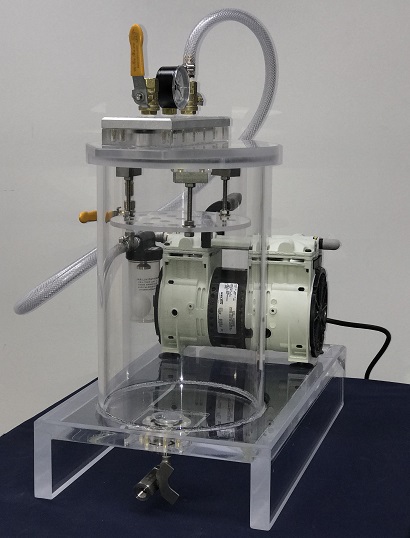

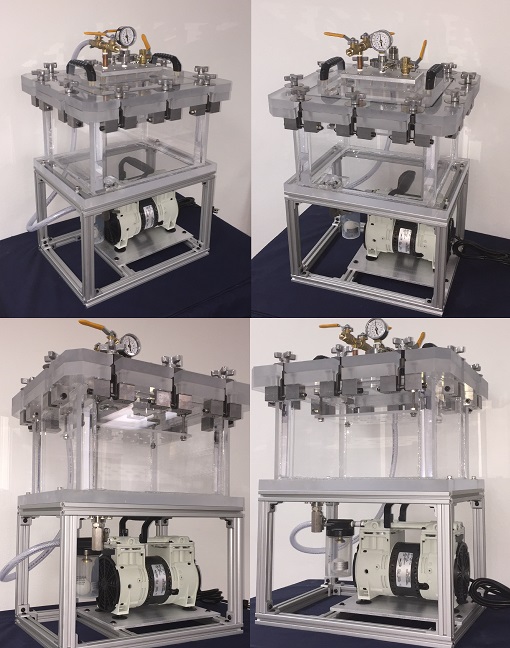

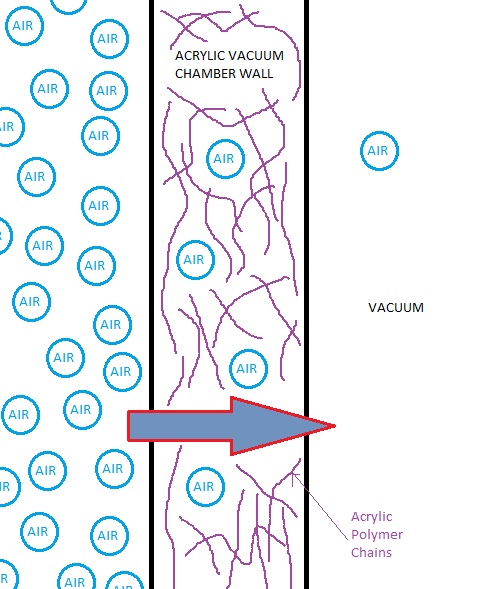

Introducing the Pressure Decay Leak Tester NANO made by Sanatron. Test three (3) specimen at once with this two channel pressure decay leak tester! Phenomenal! A pressure decay leak test works by filling the test specimen with pressurized air, closing the valve, and watching the drop in pressure. If there is a leak, the air will escape through the leak and hence decrease the specimen pressure. This drop in pressure is explained by a leak. On the other hand, if the pressure stays the same, or does not change by much, it means that there are no leaks from which the air can escape; therefore the specimen is leak tight, no leaks are observed, and this is a PASS. You are looking at the world?s simplest Pressure Decay Leak Tester! Every component, every interaction, every step along the way was designed and build with ease of use in mind. We followed the philosophy of Antoine de Saint-Exupery: "(Design) Perfection is achieved, not when there is nothing more to add, but when there is nothing left to take away."

This machine is fully setup and ready to go! And the ease of use will allow you to be leak testing your parts same day. Never worry about having to call the manufacturer for training or technical support. With our free online educational training videos and resources, you can learn how to operate this Pressure Decay Leak Testing Instrument and start testing your parts in less than 15 minutes. Your line operators can also be trained in minutes on how to perform a leak test. As with everything we envision, design, and make here at Sanatron, we always follow our core values one of which is Engineering Excellence. This means that the performance of our Pressure Decay Leak Tester as far as sensitivity, accuracy, resolution, leak detection ability, and workmanship is better or at par with any of our competitors. Nevertheless, with a much-simplified leak testing instrument, we are happy to offer our pressure decay leak tester to you at a much better pricing.

Please Note that you may need to have a custom test fixture designed and built for in order to start testing your specimen. Please contact us if that is the case because we have built countless test jigs and fixtures for our pressure decay leak testers. You will be surprised how simple it is to design a test fixture that is user friendly. NOTE: Calibration Certificates are available upon request. Contact us if you have any more questions.

We have many more resources on our website that you should check out

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.