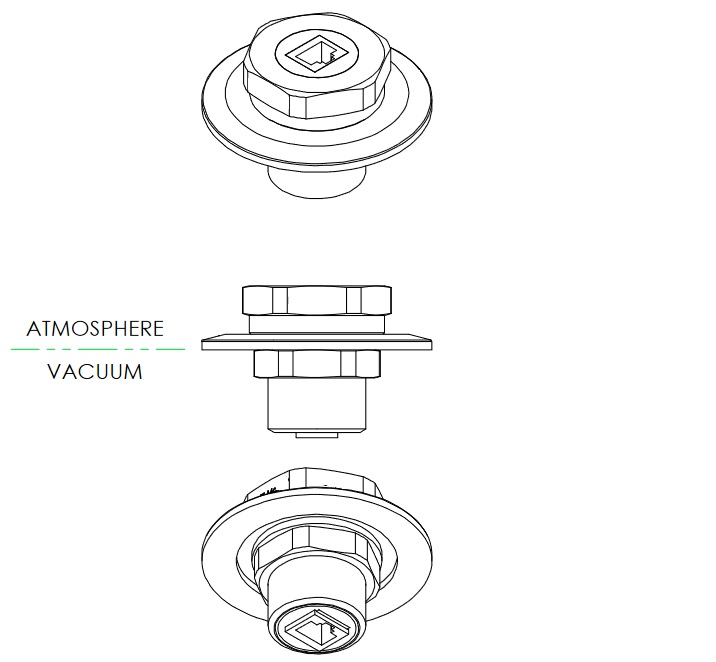

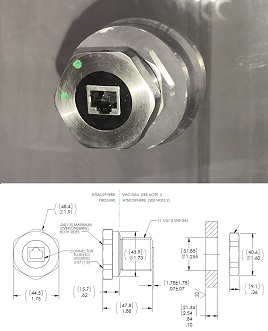

Ethernet Vacuum Feedthrough, CAT5,CAT6, RJ45, NW50, Dual Sided Connector

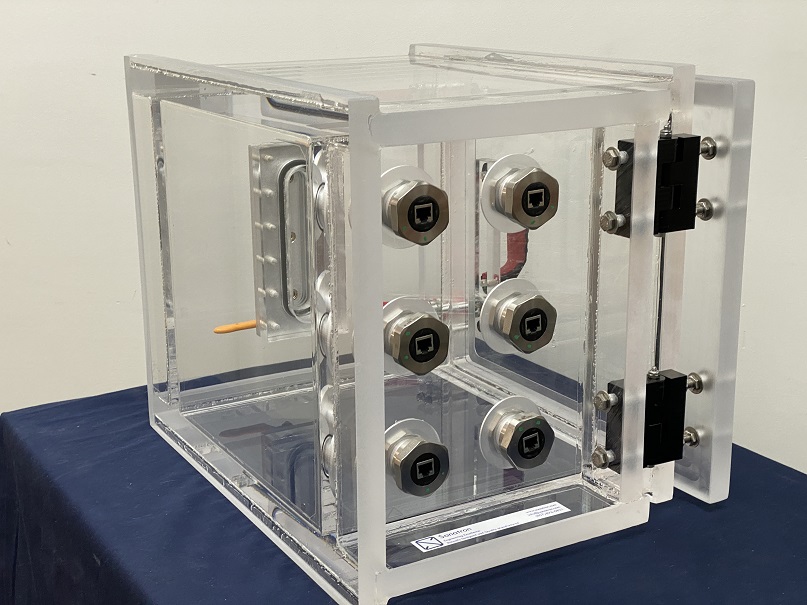

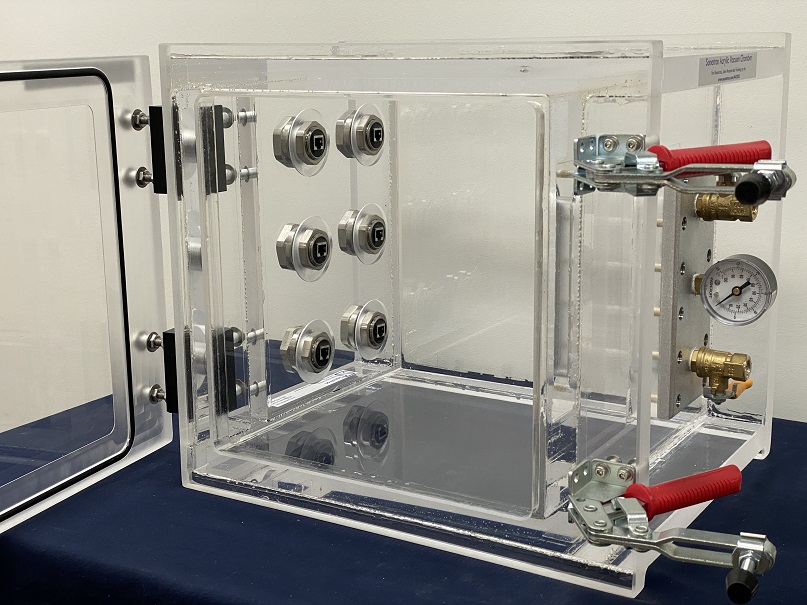

Additional Images of Ethernet Vacuum Feedthrough

Our Ethernet Vacuum Feedthroughs can be customized and applied in any way imaginable. Please take a look at additional images of our Ethernet Vacuum Feedthroughs and it application examples.

Supporting Resources

Product Specifications

Features

Description

An Ethernet Vacuum Feedthrough is a component that will enable you to run ethernet cables into the vacuum chamber from the outside to the inside of the chamber during vacuum operations without compromising the vacuum.

The Ethernet feedthrough is connected via an Quick Flange QF50 / NW50 / KF50 to an ISO NW 50 port. In addition to this component, you will also need a clamp (either wing nut clmap, or bulkhead clamp) and a NW50 Centering Ring to connect this component to your vacuum chamber and create an hermetic seal.

This vacuum feedthrough is compatible with RJ45, CAT5, CAT6, and ethernet LAN connections. Feel free to contact us if you have any more questions.

You may be interested in some of our other items

We make Robustly Designed and Quality Engineered Systems. Check out some of our other items we carry that you can combine/integrate with your systems or projects.