Vacuum Chambers are commonly used to perform experiments on Biotech instrumentation and chemistry; including PCR essays and bioreagents. The field of Molecular Biology Diagnostics has seen tremendous growth over the past several decades. The latest developments in Biotech are simply remarkable.

In order to continue the phenomenal research and development growth and to keep competitive in todays marketplace, you must select the most extraordinary companies such as Sanatron.

Which is the reason why our extraordinary client contacted us: the mission was to build a Vacuum System capable of performing greatly in order to help them crush it.

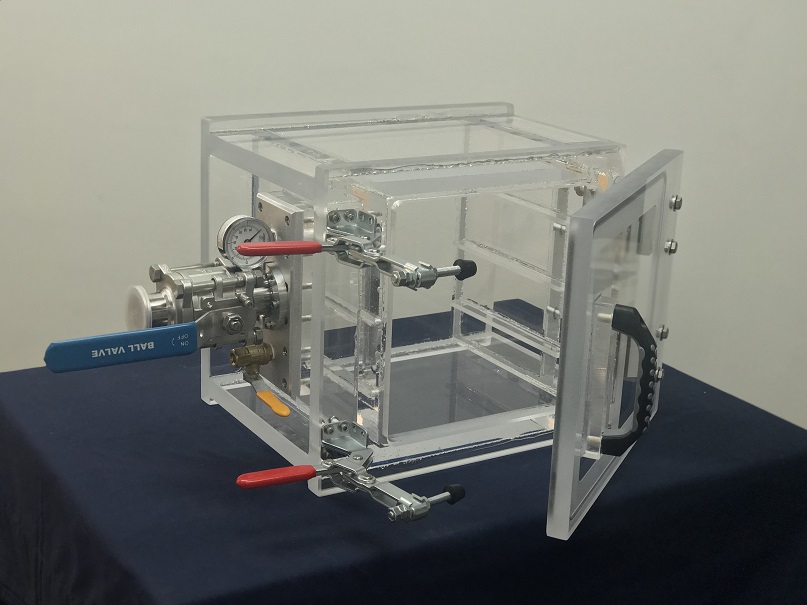

This is a complete Vacuum System it consists of a Clear Acrylic Vacuum Chamber, Framework Structure, a vacuum pump and several vacuum feedthroughs. The Acrylic Chamber is a 24-inch cube inside dimensions, hinges side door, front loading. It is sitting on a table structure that is specifically made from 8020 Inc components to fit this chamber and design. Below the chamber is an industrial vacuum pump that is connected through NW25 port to an NW25 Vacuum Valve. You can notice the dial vacuum gauge and an NPT valve connected to the same port plate as the NW25 vacuum valve.

The clear vacuum chamber is customized as well. On the right hand wall, it also features a digital Instrutech Vacuum Gauge capable of displaying the absolute pressure in Torr and millitorr. On the Left wall you can see an NEMA-15 electrical outlet, two ethernet ports, and one Subminiature D Vacuum Feedthrough. This system is also placed on fully lockable swivel casters which enable our client to maneuver this vacuum system into any room or facility they chose.

Are you looking to crush it? Contact Us to discover how we can help you with your vacuum system needs.

We have many more resources on our website that you should check out

We make Robustly Designed and Quality Engineered Systems. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers