Ever wondered how to leak test packaged volatile products? Do you know that there are countless unstable products out there that have to be leak tested as part of quality control? By volatile we mean products which ignite, explode, shatter, melt, or are hazardous. Keep in mind that hazardous material for whatever reason has be undergo quality control as well.

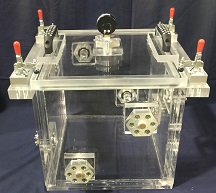

This is what our client wondered too. They wondered how to perform a quality leak test on their volatile product safely. They came to us because we manufacture clear acrylic vacuum chambers which are incorporated into Bubble Leak Testing Systems. As with many of our happy clients, we will not be able to tell you what exactly they were doing as that information is proprietary. However, we will be glad to show you what we made for them and how it helped them.

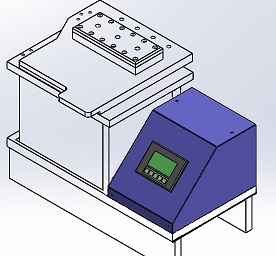

What we built for them is a Large Bubble Leak Testing System. The Acrylic Tank Dimensions are 25 inch Wide, 14 inch Deep, and 18 inch High. The Lid is hinged and supported by a Gas Spring which will keep the lid open in order to enable the operator to load the tank with test specimen without having to hold the lid with one hand. We also provided them with a 6 CFM Uniweld Vacuum Pump and a Vacuum Pump Protection Valve. This protection valve will prevent tank water from accidentally entering and damaging the vacuum pump. We also provided them with an Instrutech Digital vacuum gauge to enable them to have better vacuum readings from their bubble leak testing system. There is also a drain valve which comes with every one of our bubble leak testing systems. Finally, if you look closely, you can a hole cut out into the right wall. Our client asked us to cut this hole because they wanted to connected a rotary feedthrough to it so that they can manipulate the test specimen from the outside during vacuum operations. This whole system is placed onto table frame structure with lockable swivel casters making this a portable bubble leak testing system.

Are you working with difficult to test products? If you are, please Reach Out to us and let us know what you are looking to do. We would you love to have the opportunity to look at your project.

Similar Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers