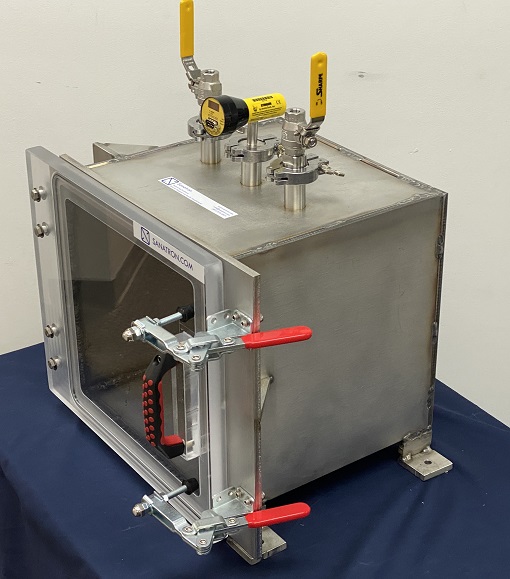

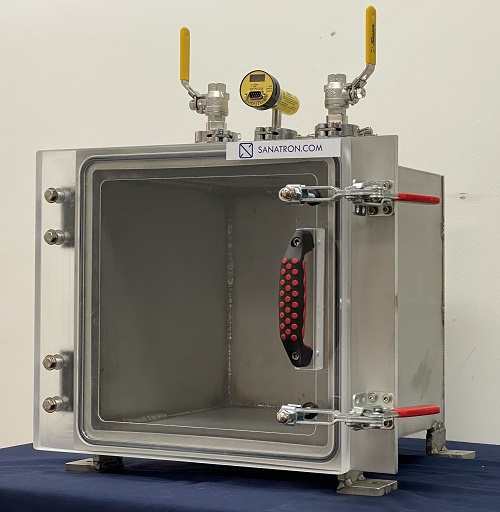

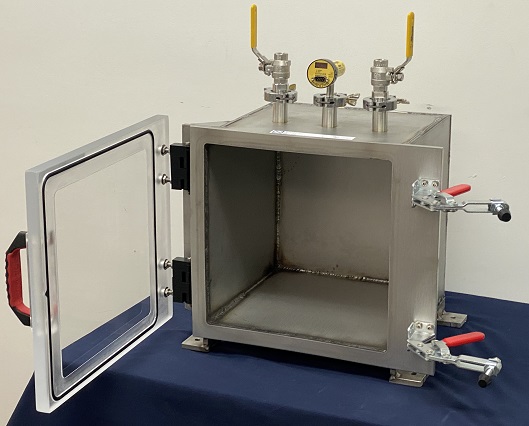

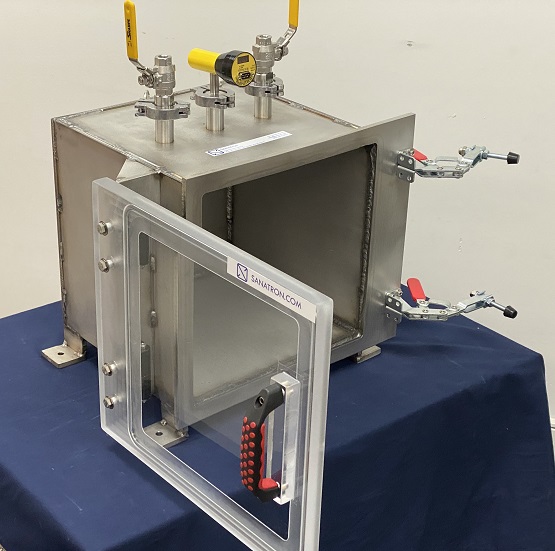

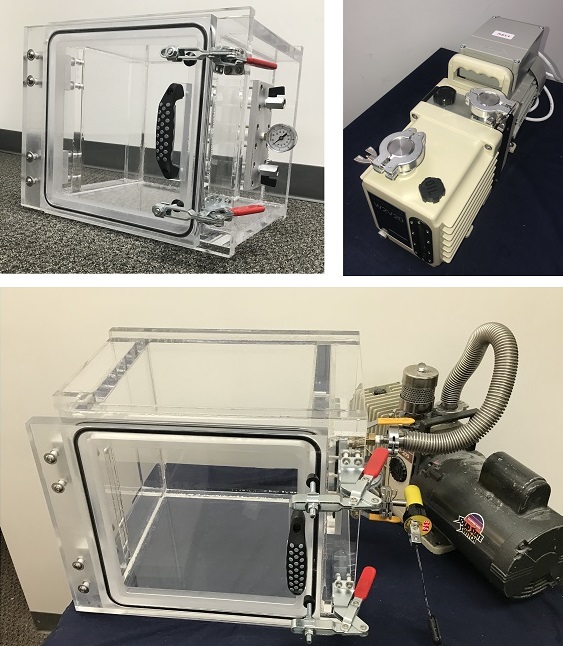

Stainless Steel Vacuum Chamber, Cube, 12 inch inside dimensions, Front Load Model, Clear Acrylic Front Door

Additional Stainless Steel Vacuum Chamber Images

Please take a look at additional product images of our Stainless Steel Vacuum Chambers with Clear Acrylic Front Door. All our chambers can be customized. Please contact us if you are looking for a custom vacuum chamber.

to consistently perform and meet your needs!

Product Specifications

Features

Description

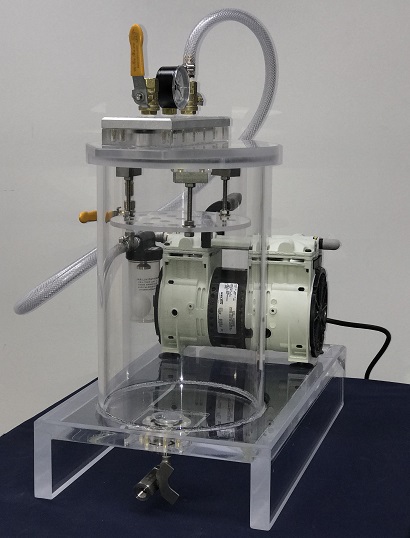

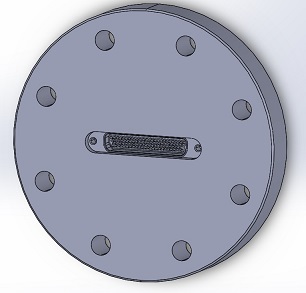

You are looking at our Stainless Steel Vacuum Chamber with Acrylic Front Door. The Lid Material is Clear Cast Acrylic which houses the O-Ring. The inside Dimensions of this chamber are 12 inch Wide, 12 inch Deep, 12 inch High. This Vacuum Chamber is rated to 1 micron absolute pressure (10-3 Torr). The door is front loading and hinged. Included with this chamber are a robust and ergonomic Lid Handle, door hinges, two ?get-out-of-the-way? toggle clamps, and three NW25 Ports.

The operational range of stainless steel vacuum chambers is -190 Degrees Celsius and +290 Degrees Celsius. In addition to a broad operational range, Stainless Steel vacuum chambers are more chemically resistant to thinners, alcohols, and acetones.

Please note that the three NW25 ports on this vacuum chamber are open and you will need to purchase a vacuum valve, a venting valve, and a vacuum gauge separately. We would recommend that you go with a NW25 Vacuum Valve, a Digital Vacuum Gauge (higher accuracy and resolution), and a 1/4 inch NPT Venting Valve. However, what valves and gauges you select will depend on your application. Keep in mind that we do offer connection hardware and vacuum pumps to go along with the vacuum chamber as a fully system.

One of the most common mistakes people make is to try to source every single part for their vacuum system themselves. The end results is either the wrong vacuum pump, the wrong connection hardware, or a sub optimal Vacuum System.

We have sourced the most appropriate vacuum pump for you so that you don’t have to. Get your vacuum chamber and vacuum pump and connection hardware for a complete vacuum system! Click here to get your Vacuum Pump and Vacuum Chamber System

WAIT! Take a look at similar Items you may like…

We make Robustly Designed and Quality Engineered Systems. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.