Medical Devices are products such as syringes, catheters, pacemakers, and other electronics fabricated for the therapeutic medical purposes. All Medical Devices produced and sold in the US must be regulatory compliant with the Food and Drug Administration (FDA). Failure to comply with the FDA can lead to severe consequences. If you were to ask me what the purpose of the FDA is in one sentence it would be: “The Purpose of the FDA is to protect the end user from harm”.

Regardless of your stance on regulation, whether we have too much or too little; there is one fact we can both agree upon: We want our medical devices to be quality products and thoroughly tested. No patient ever walked into the operating room and said: “Give me the crappiest Heart Lung Machine you got!”

This is why our medical device manufacturer came to us. Their mission is to help the healthcare industry to design and develop solutions to Medical Devices by offering Comprehensive Lifecycle Services To Support Regulatory Approvals and the maintenance of Medical Products.

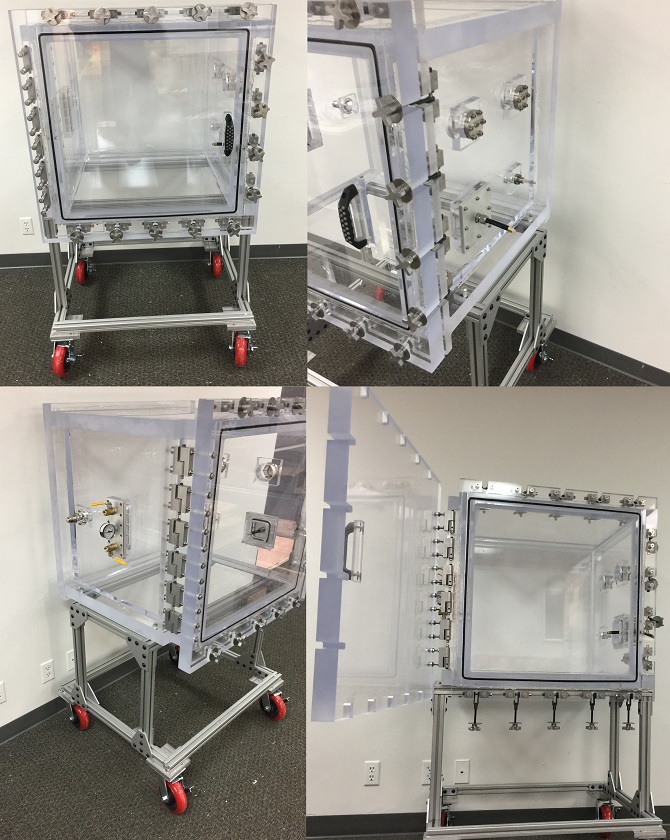

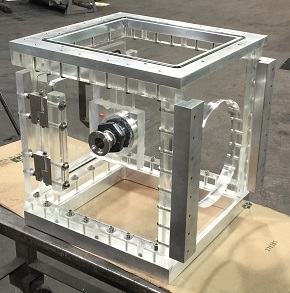

We built a Fully transparent Acrylic Vacuum and Pressure Chamber with additional vacuum feedthroughs. Including having a fully functional Vacuum Chamber capable of medium vacuum levels about approximately 0.5 Torr, they also required a 5PSI Overpressure Option in order to pressurize several of their test specimen. A vacuum chamber having the inside dimensions of 24 inch cube (2 feet cube) is quite large and heavy. This is why we placed this chamber onto a table frame structure with 4 fully lockable swivel casters. This enables the medical device development engineers to move the chamber with ease from room to room.

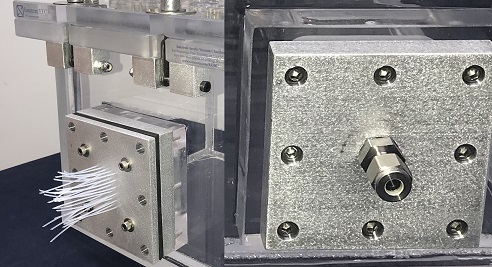

The door to this chamber is a hinged door. It is clamped with swing thumb clamps during overpressure operations. On the Right wall, there are total of four vacuum feedthroughs. Two are a multipin, Type-D, 9 pin connectors. The third one is a 25 Amp, 1000 Volts, 4 pin vacuum power feedthrough, and the fourth one is a vacuum liquid feedthrough. All 4 feedthroughs can be operated at full vacuum without compromising the vacuum or pressure inside the chamber.

On the left wall, you see two valves and a vacuum gauge. Behind the valve port assembly is a pressure relief valve that will pop open at 10PSIG in the event where the operator forgot to turn off or down-regulate the overpressure for this vacuum/pressure chamber

Do you work with Medical Devices which are required to be Regulatory Compliant? If you are, Contact Us and find out how we can help you make better medical products.

Some of our Popular Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers