Nutritional supplements have been popular since the invention of vitamin pills. Every day there is a new supplement, root, plant, and molecule promising break through benefits. Fortunately, nutritional supplements have their benefits and when coupled with a heathy lifestyle, nutritional supplements have the power to improve our lives enormously.

When manufacturing and packaging supplements, it is vital that the manufacturer properly seals the product. A good seal will extend the shelf life of the product while protecting the consumer.

The simplest package quality test that can be performed on heat sealed nutritional supplements is the dry vacuum test. The dry vacuum test will confirm two things. First, the test will confirm that the heat sealed items can be transported by air and at higher altitudes. Second, the test will confirm quality heat seal integrity of the batch.

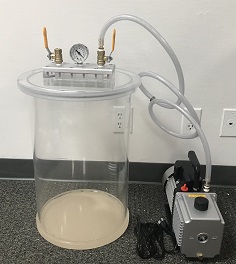

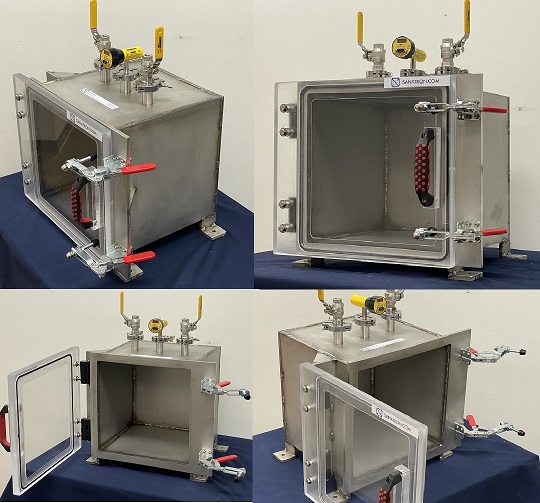

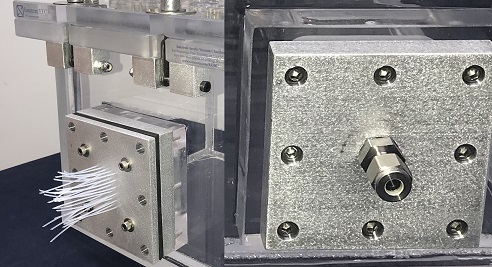

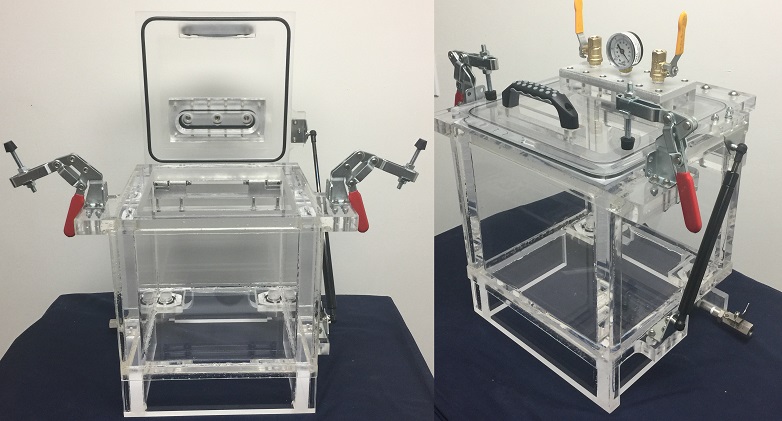

All that is needed is a Transparent Vacuum Chamber, connection hardware, and a vacuum pump. We offer vacuum chamber with pump systems tailored specifically to your project needs. Contact Us to find out how we will help you immensely.

Did you know that we carry a many more products?

We make Robustly Designed and Quality Engineered Systems. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers