Dye ingress is most commonly used as a container closing integrity test in order to quality test sterile products. This test is mostly done in the Pharmaceutical Industry or Medical Packaging Industry as means to test for product defects in rigid container. It is based on the concepts set forth by the ASTM 4991 and used as a seal integrity test. In addition to rigid containers, blister packs and heat-sealed trays, can also be tester in accordance to this method.

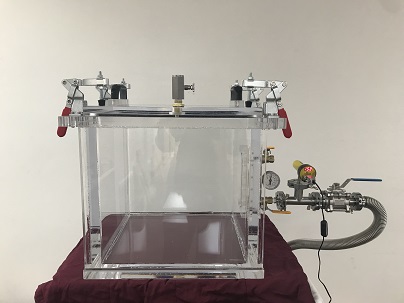

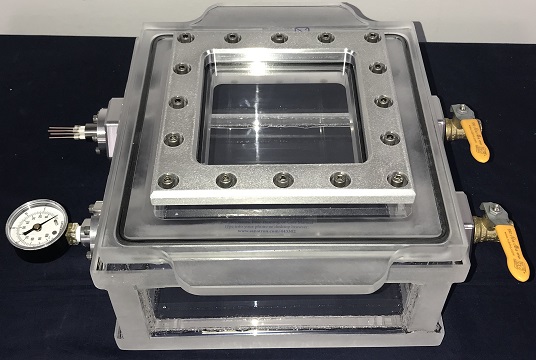

Our Acrylic Vacuum Chamber is the perfect candidate for the ASTM 4991 Test because the method calls for a “transparent test chamber”.

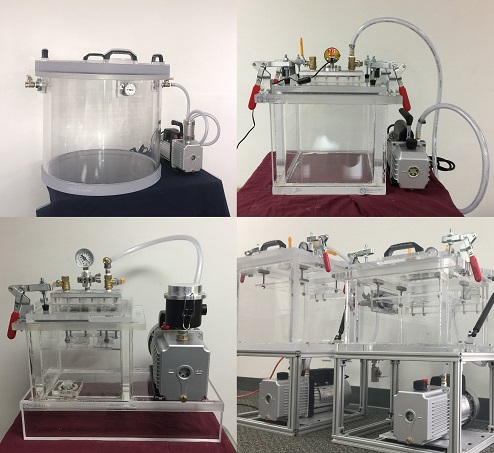

Fortunately, you have many to choose from since we have a large selection of transparent test chambers. Each of our vacuum chambers comes as a standard with a dial vacuum gauge and two vacuum valves (venting valve and vacuum valve)

Are you performing container closing integrity tests? If you are, contact us so that we can help you with your quality control procedures.

Did you know that we carry a many more products?

We make Robustly Designed and Quality Engineered Systems. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers