A hearing aid company designs, manufactures, and assembles sophisticated acoustic parts such as special microphones and speakers. In order to test the microphone and speakers which go into hearing aids, as well as fully assembled hearing aids, it is imperative to know at which point the failure happens. Does the failure happen due to elevation or due to improperly designed and built hardware or software?

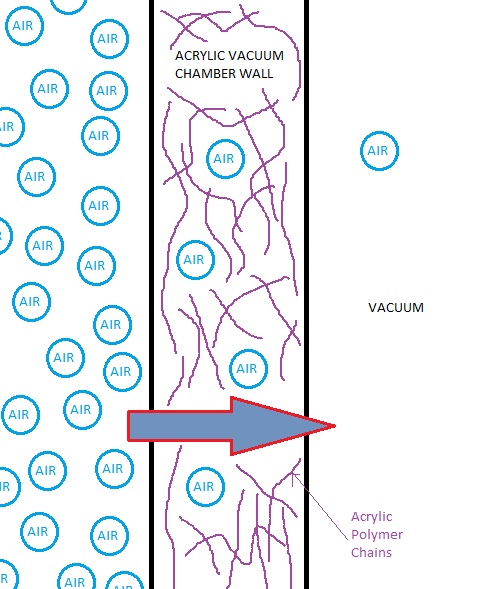

To eliminate any acoustic sound entering the microphone or emitting from the speaker, a vacuum chamber is utilized. Sound does not travel in vacuum since sound is simply vibration of air molecules. By pulling the chamber down to a vacuum of less than 100 millitorr, any exposure to background sound sources is eliminated. The only thing that is left is sound generated from electrical sources such as improper circuit design or background radiation. This also helps to determine how sophisticated audio equipment interacts with wireless internet signals or cellphone signals. There are countless sources of noise or electrical feedback which can cause the hearing aid device to fail.

Fortunately Acrylic Vacuum Chambers that are clear and transparent will enable to acoustic development engineer to perform high integrity testing on hearing aid circuits and assemblies.

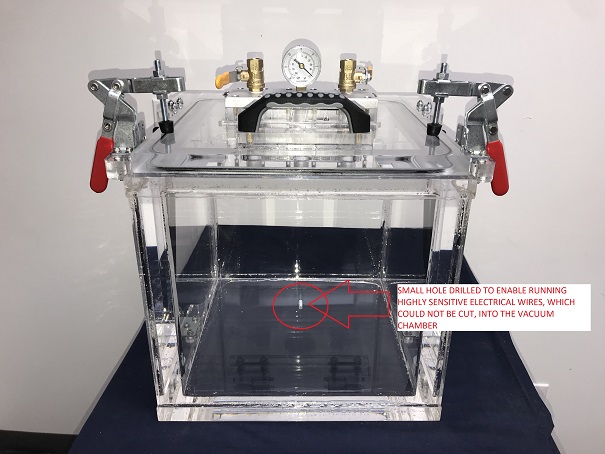

You are looking our custom made vacuum chamber, 12 inch cube, top load model with a spring supported lid. There is also a small through hole which was drilled to enable to experimenter to run wires from the outside to the inside. We were not able to use a vacuum feedthrough as the requirement was that we could not cut the testing wires because cutting the testing wires would create electrical noise and interference. At this point, the experimenter will plate a Buna-N film, over the hole, then she will run the electrical wire through the Buna-N hole and through the hole drilled into the side wall of chamber.

Did it work? Yes, we were able to get a good seal and pull the vacuum down to less than 0.1 Torr. Sometimes additional Vacuum Grease was used to seal some leakers. The experimenter was able to go down to specified 0.075 Torr and stay at that level for some time in order to complete their analysis.

Are you conducting tests on high performance acoustic and electrical circuits. Contact Us to see how we can make your experiments better.

Some of our Popular Items

We make Robustly Designed and Quality Engineered Systems. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers