Nuclear imaging is quickly becoming more and more sophisticated and images unimaginable twenty years ago are become reality – think about the recent image of a single atom. Nuclear imaging is detection is a highly technological field.

A nuclear scintillator converts gamma rays which are invisible to the naked eye into electrical signals and enables the researcher to detect the energy of the gamma ray as well as the intensity. They way it works is when a gamma ray crosses into the scintillon crystal, it will start interacting with the electron clouds of the crystal molecules. This interaction will slowly begin to slow the gamma ray down while at the same time emit photons in the visible light spectrum. Conversely, the higher the energy of the gamma photon the more photons are created. The visible photons as a result of the interaction between the gamma ray and the scintillator crystal are now picked up by the photocathode, amplified, and finally converted into an electric signal. This electric signal is then processed and converted into the Gamma Ray Energy enabling the experimenter to determine the energy of the gamma ray. The result is a graph of the gamma ray energy spectrum.

In addition to being able to better detect gamma rays and quantify its energy level, better nuclear imagining becomes possible as well since the X-Rays are detected better, less X-Ray intensity is needed to yield same quality image. The fortunate result is that the patient does not need to be exposed to as much radiation leading to better treatment outcomes.

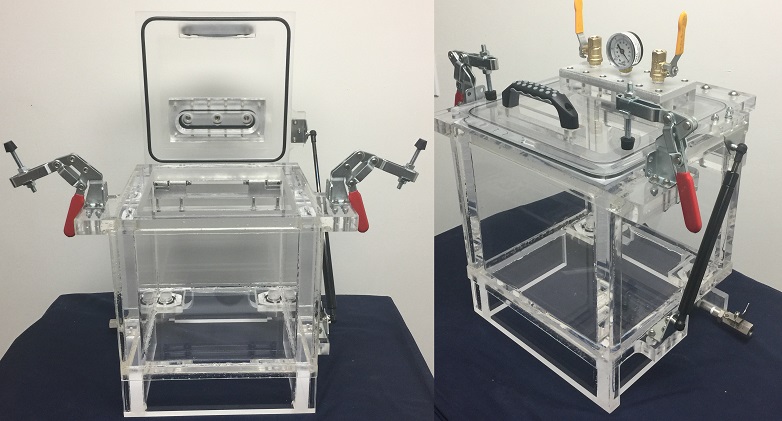

Our client was not able to tell us exactly what they were doing since their research is top secret and proprietary. This is what they told us: “The vacuum chambers are working out very well for us! We used those devices to improve one of our analytical methods and have experienced no problems at all with their functionality. We are very happy with them…”

We built a total of 9 of these Acrylic Vacuum Chambers for them. This our spring supported top load model. The lid is supported with a gas spring that keep the lid open in order to the end user to load the chamber without having to worry of slamming the lid down. In addition, we added two stainless steel drain valves on the bottom wall. The valves are elbowed and are facing out towards the sides. As a result, we had to raise the chamber up in order to provide clearance so we added a skirt.

If you are looking to improve your analytical methods and are in need of vacuum technology, Contact Us to find out why we make the best acrylic vacuum chambers in the world.

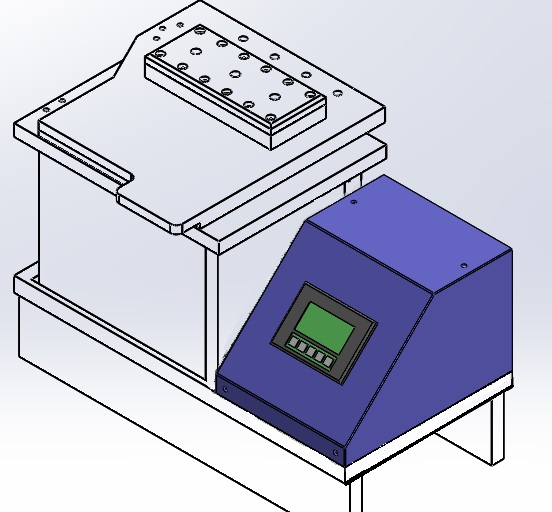

Similar Items

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers