Vacuum Testing of Lithium Ion Batteries, Thin Film, Fuel Cells, Supercapacitors, and Nano materials

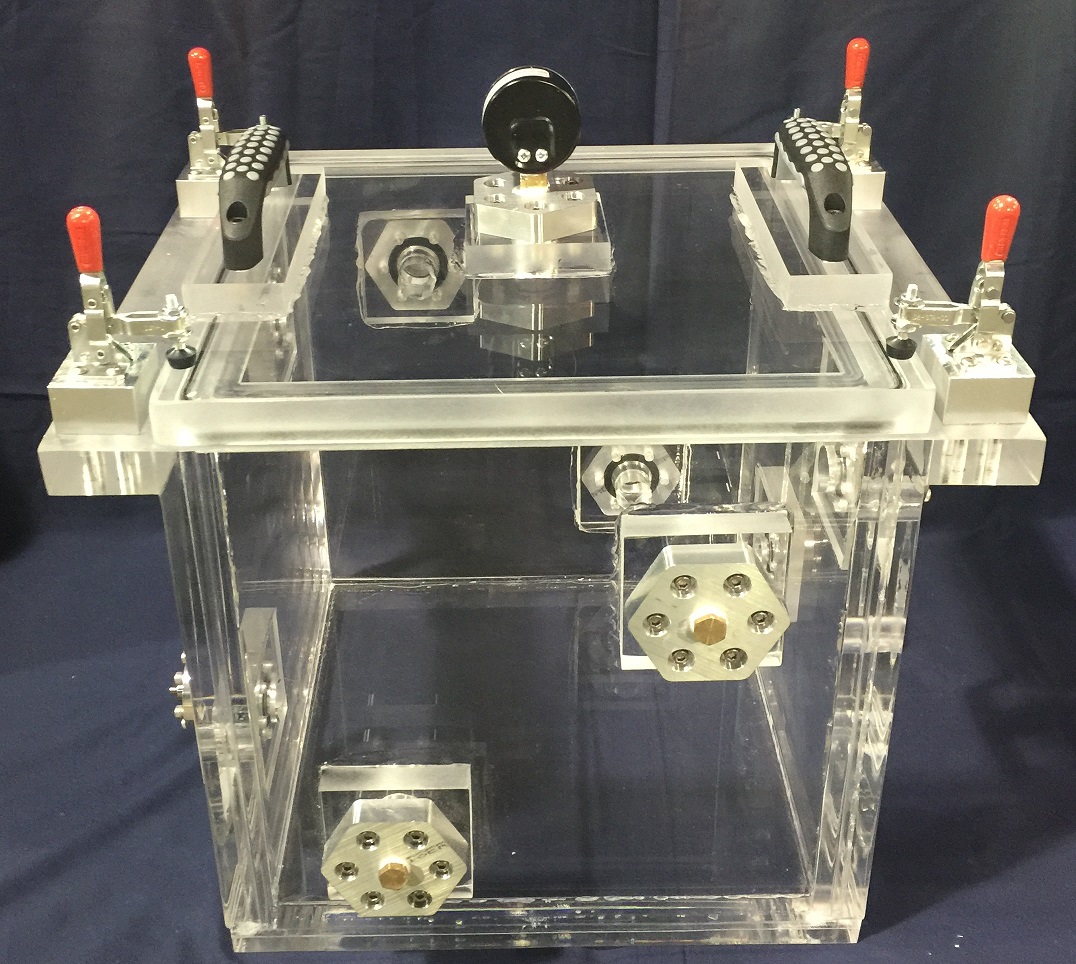

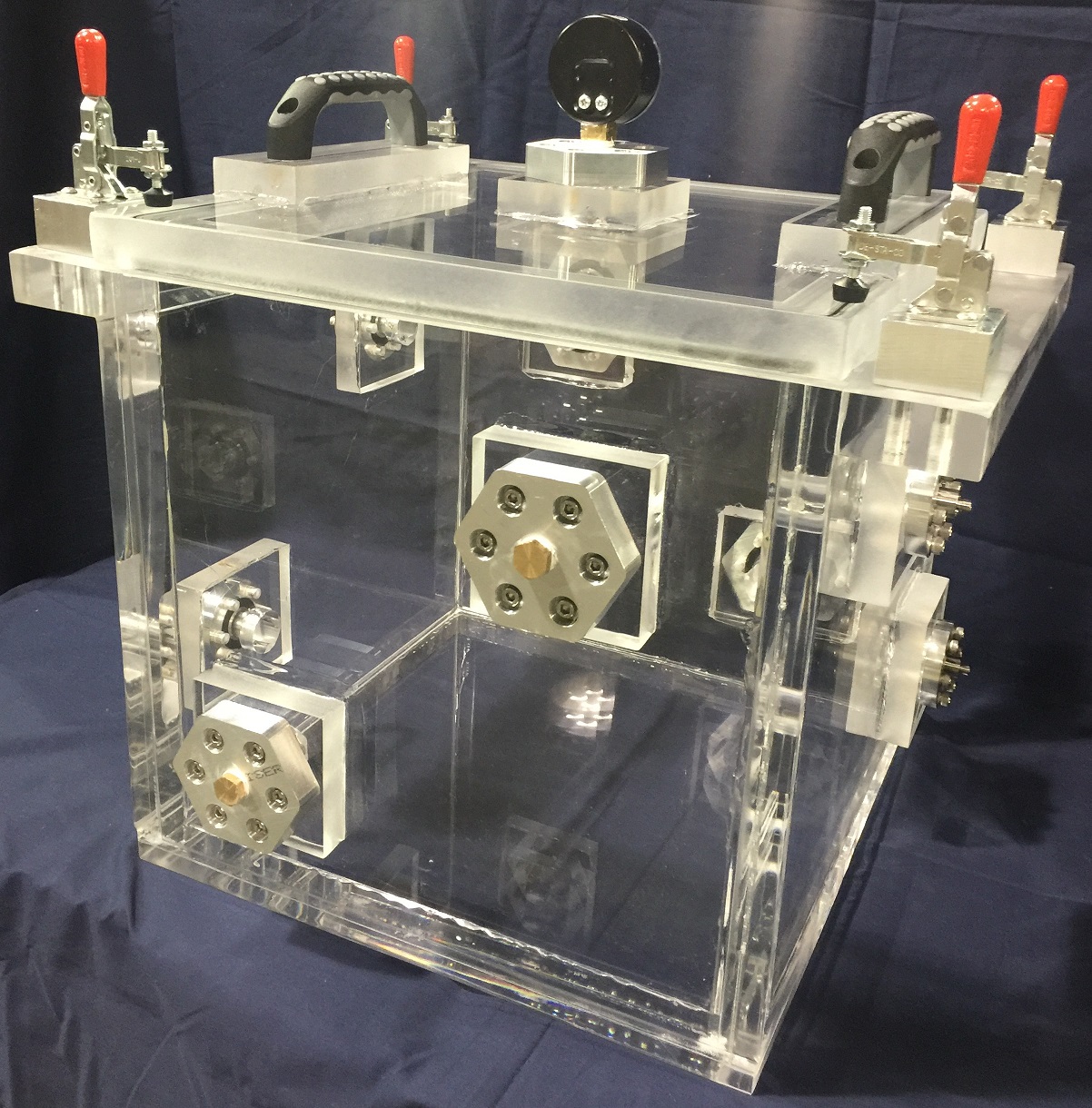

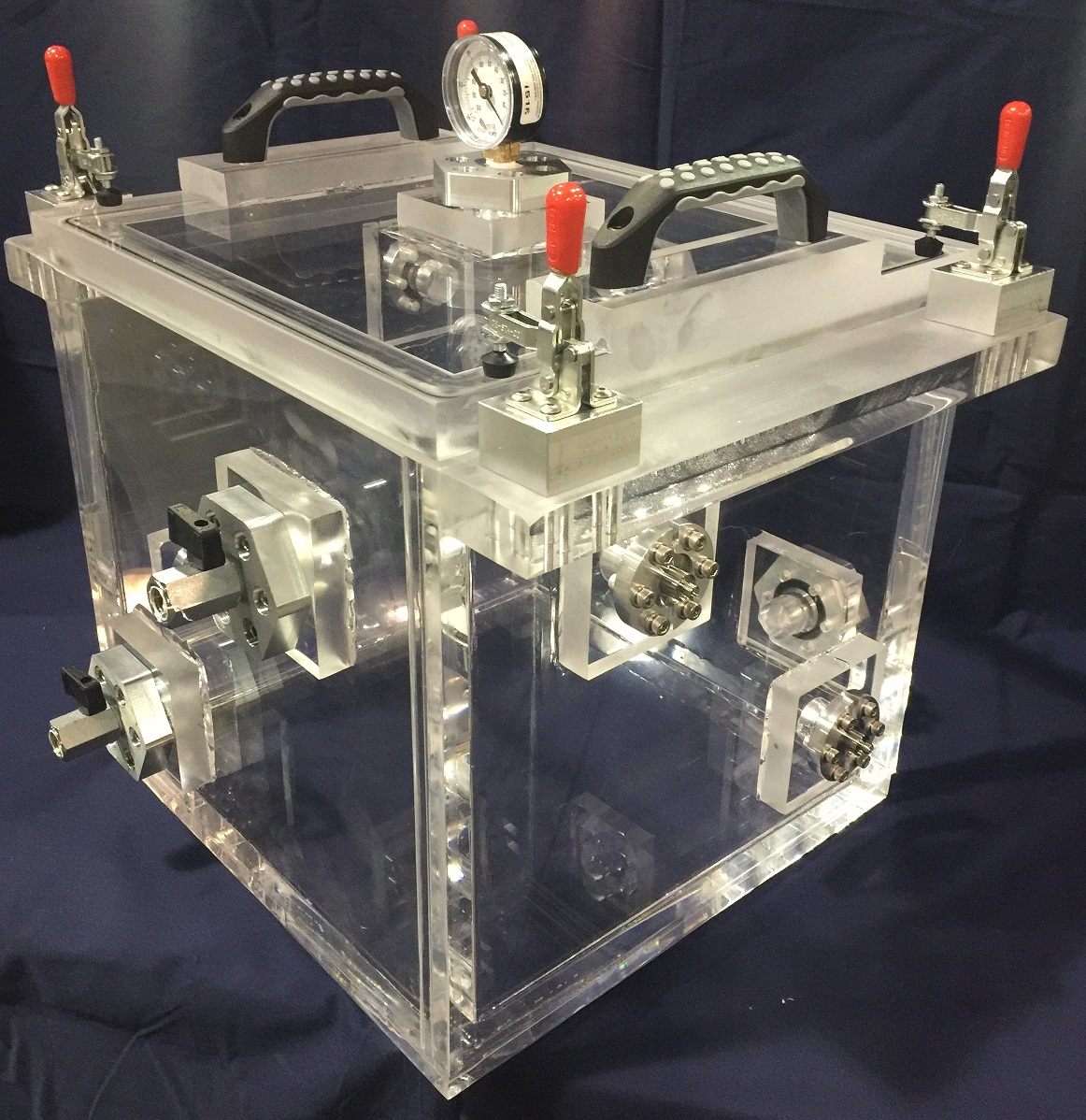

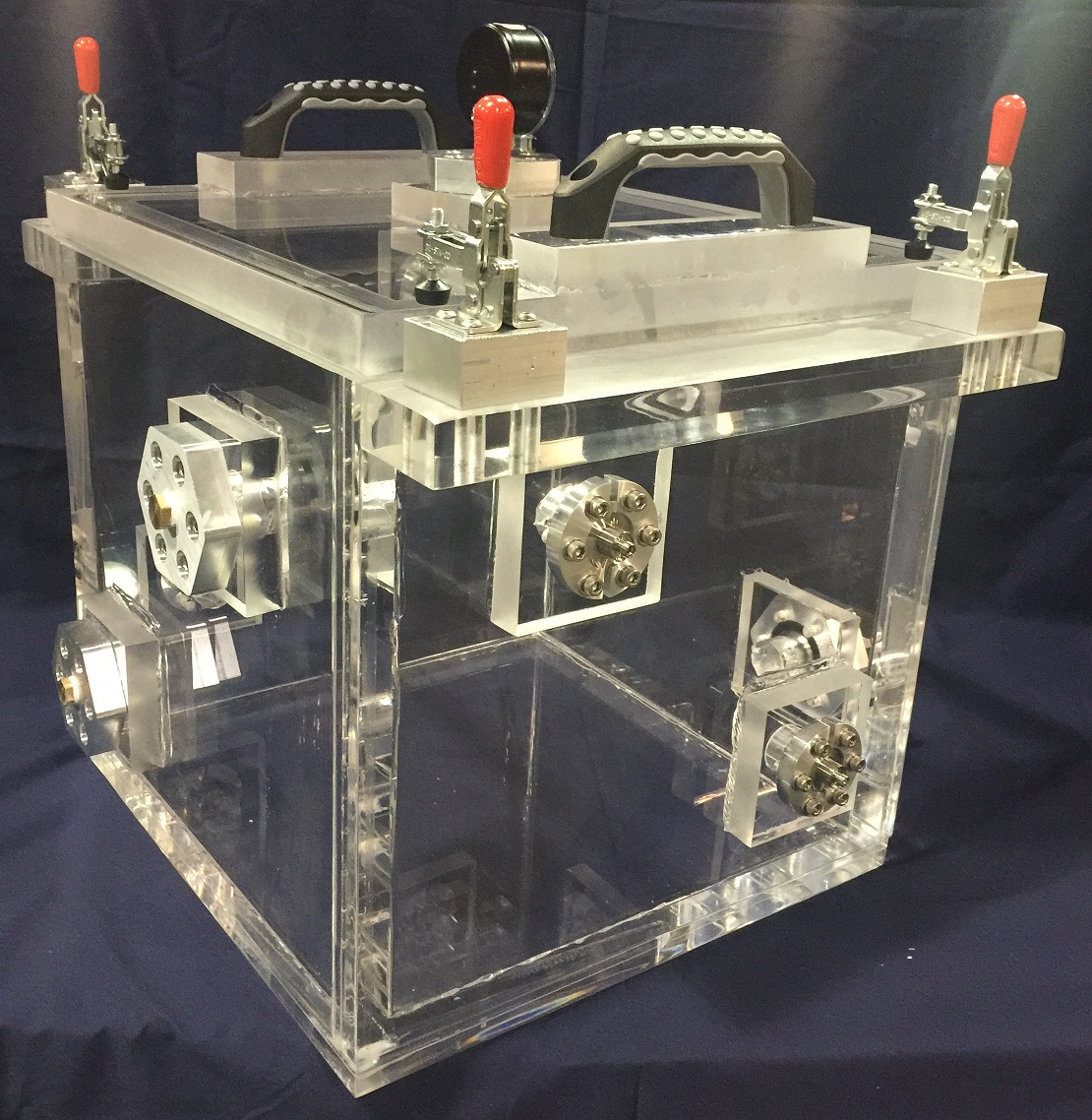

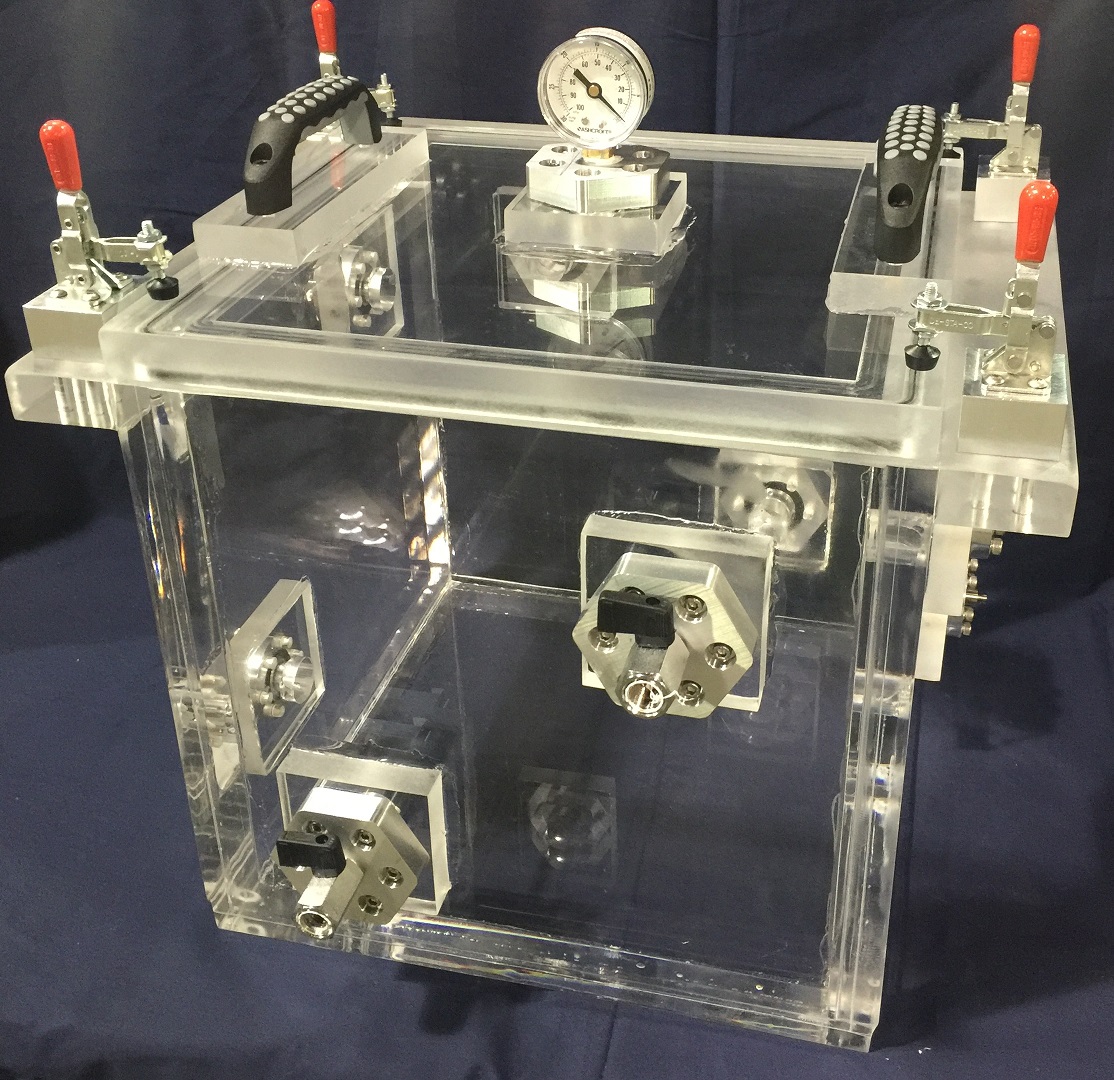

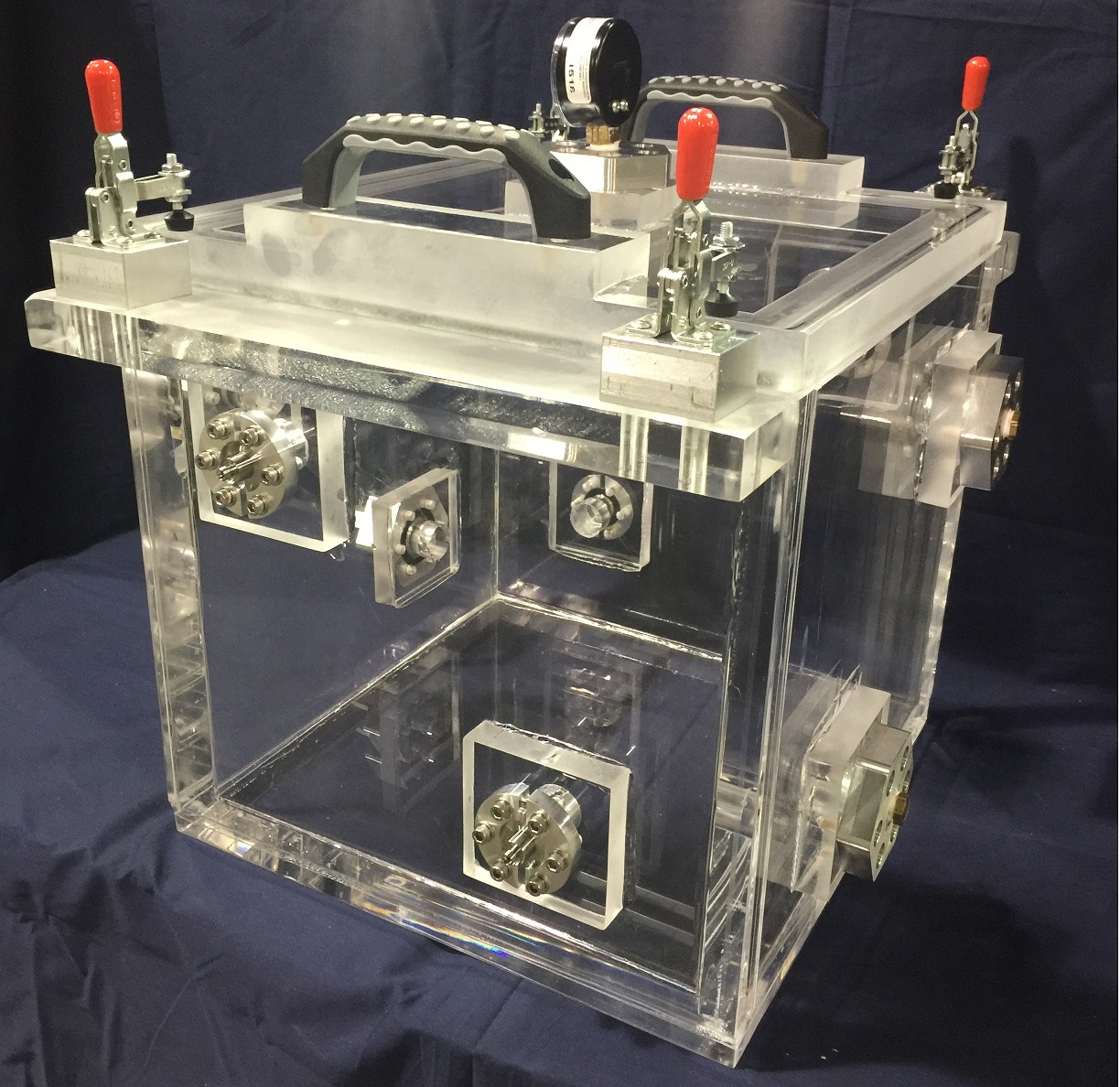

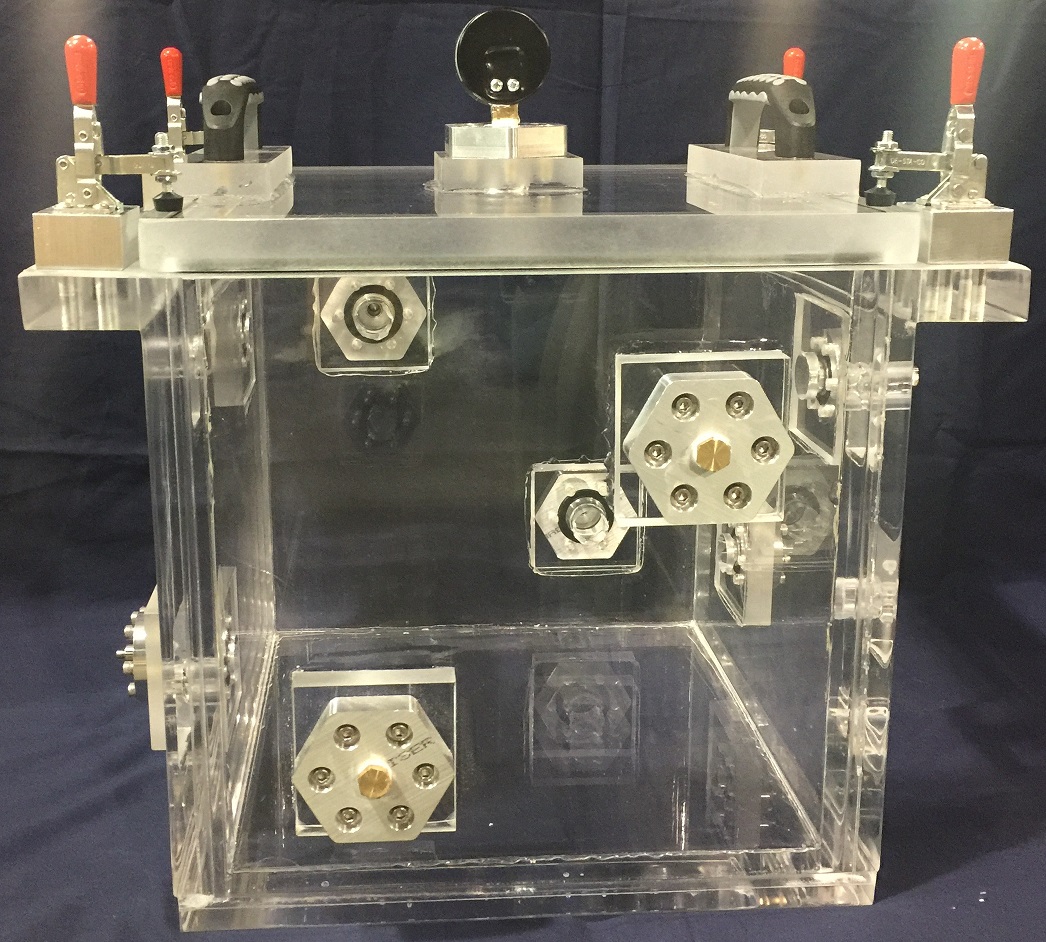

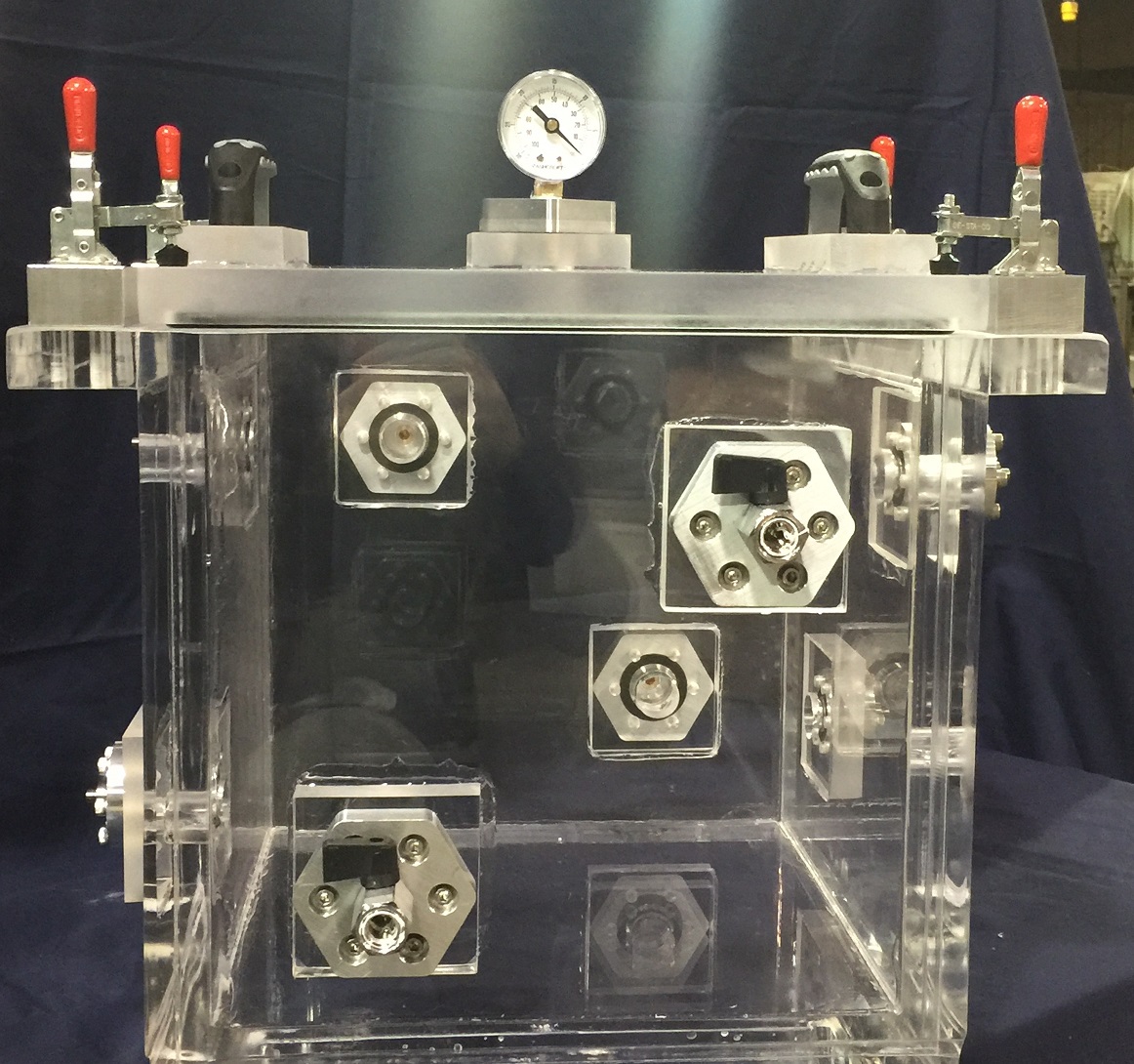

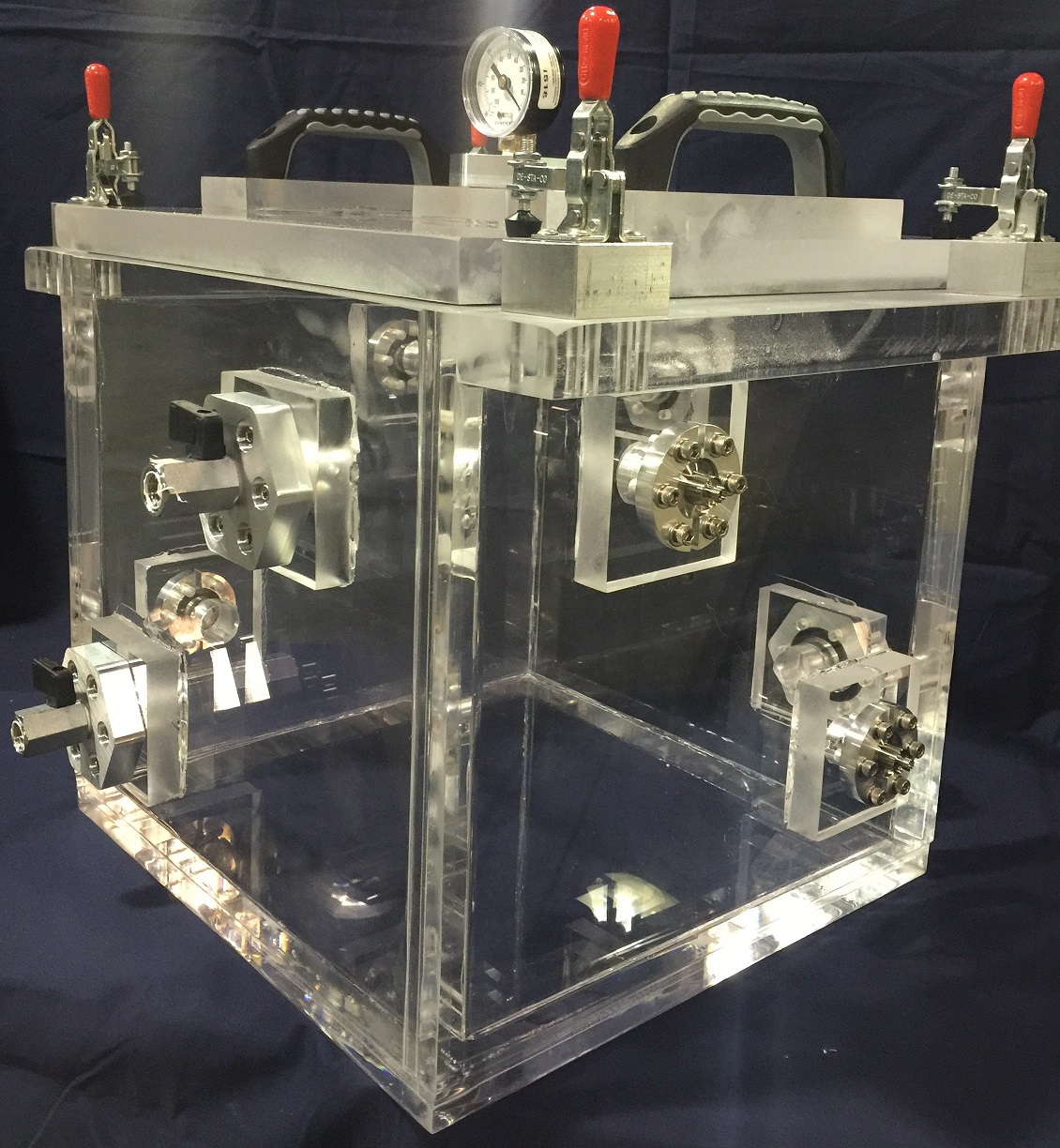

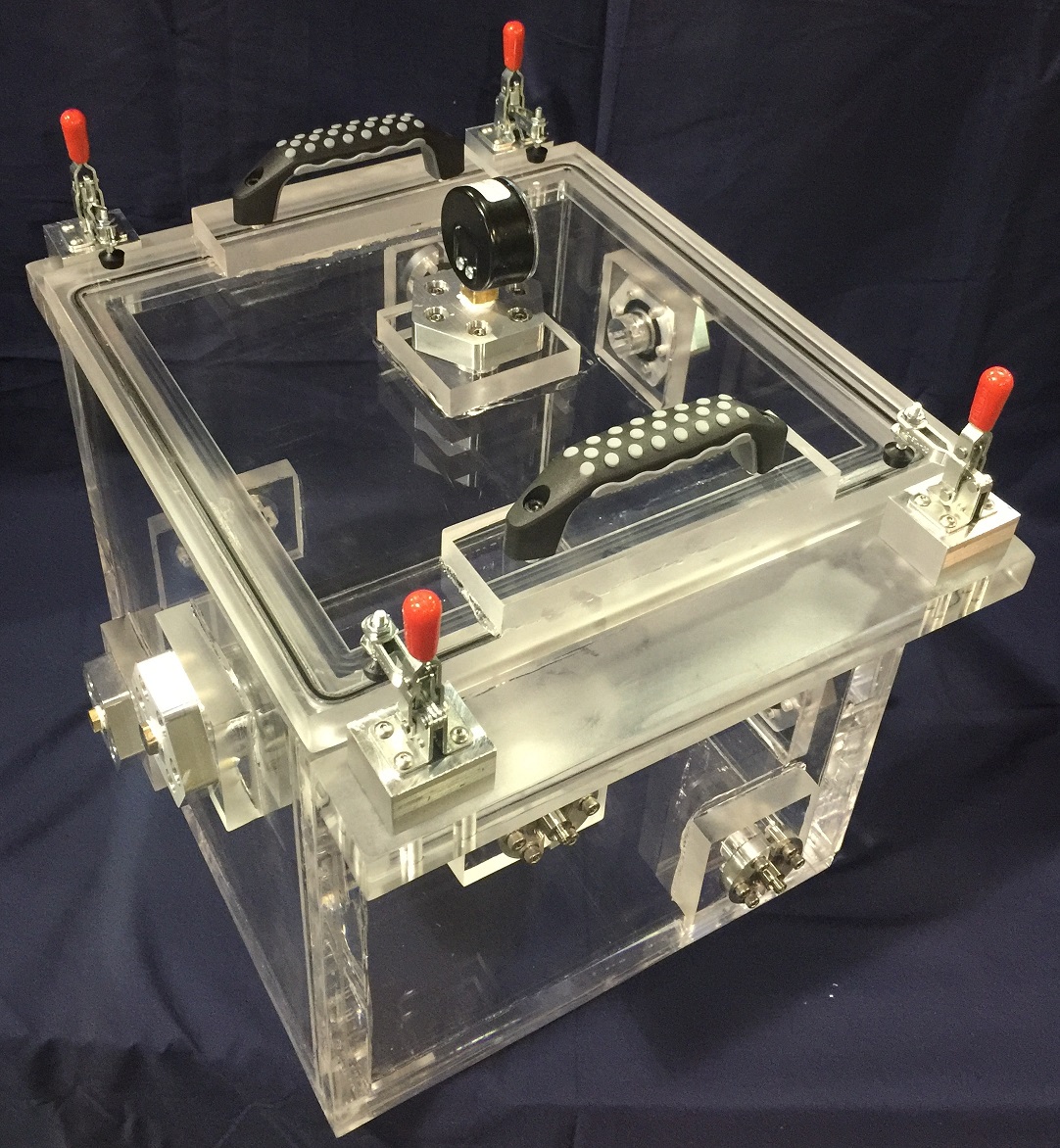

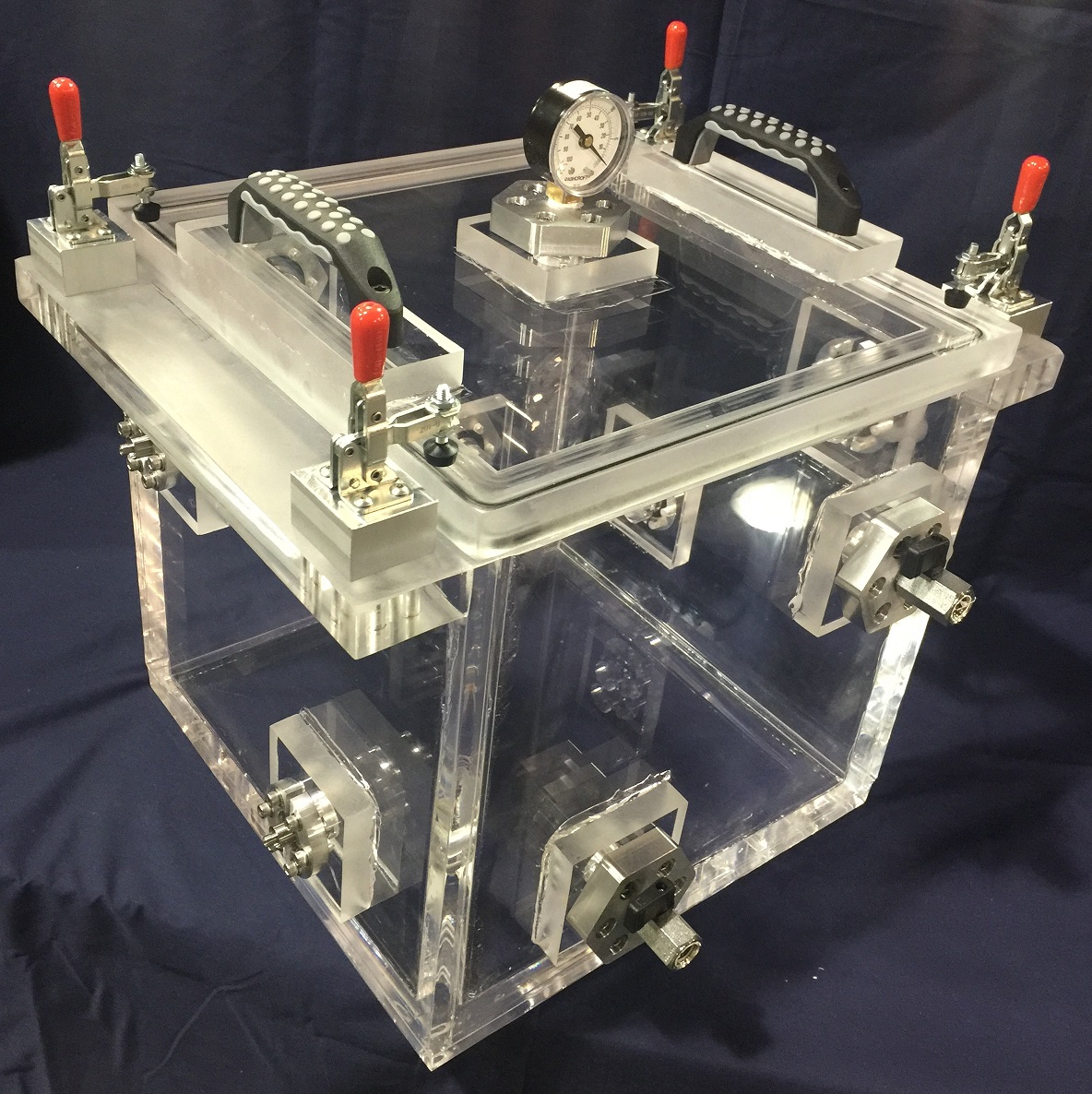

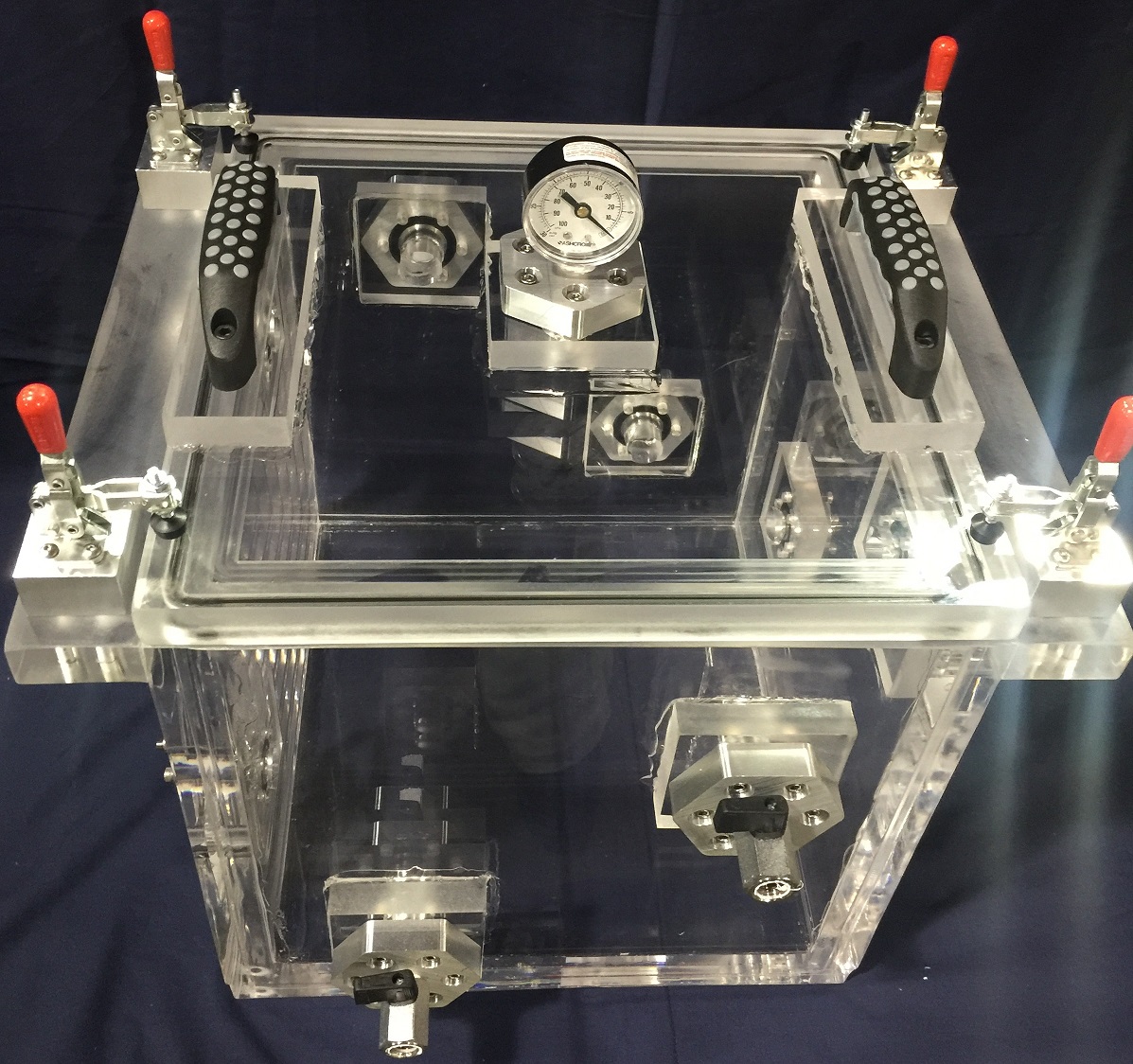

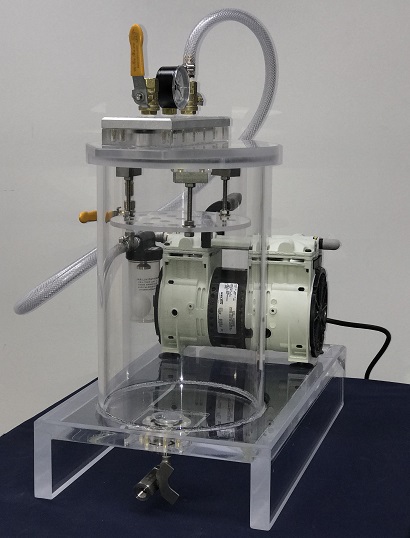

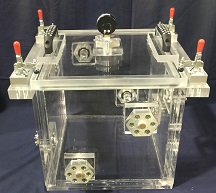

This vacuum chamber is a modification to our basic acrylic vacuum chamber 12 inch, removable lid model; except that our customer requested additional ports and electrical feed-through for testing of electrical equipment under vacuum. You know, I wish we would have asked them for more details on what they were doing with this chamber; their short and concise answer was that they were using our chamber to perform scientific work on the subjects of: lithium ion batteries, thin films, fuel cells, super-capacitors, and nano-materials testing in a vacuum environment.

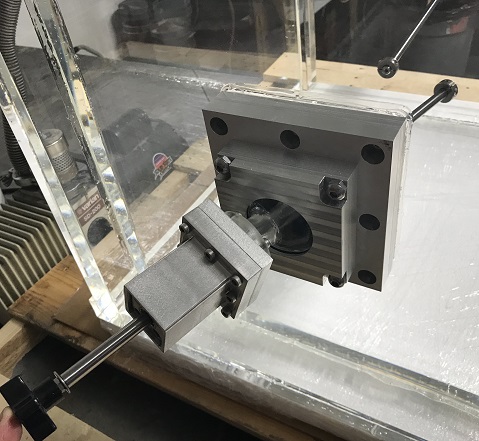

As you can see, they requested that the vacuum valve and the vent valve be placed on one side of the wall. Then they requested two more 1/4 NPT ports to be placed on the opposite side of the valves. Finally, they asked as to provide them with a total of four 50 Ohm Matched Impedance for High Frequency Transmission to 6 GHz, Air-side Connector Included, Grounded Shield, UHV Compatible feed through to be placed on the two remaining walls. In the end, we had two ports on each wall for a grand total of 8 ports.

The nice thing about these ports is that these are the standard NW16 and NW25 ports consisting of the same industry standard bolt pattern. The advantage of our ports is that they are interchangeable with any other NW flanges, centering rings, and can be clamped with a standard NW Bulkhead clamp; or any other ISO quick flange for that matter.

WAIT! Take a look at similar Items you may like…

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers