There are several occasions when you will have to perform toxicology experimentation on your engineered systems. One of them is on aerospace components and subassemblies intended to be installed on spaceships and airplanes. During spaceflight, humans exhale carbon monoxide and other gasses which can become deadly if the concentration reaches above 5%. There are also other deadly gasses which also accumulate and must be accounted for in order to ensure safe flight.

Our client, who performs toxicology experiments that aid spaceflight missions contact us to discuss how our regular vacuum chambers could be modified in order to fit their specific need. They did not tell us exactly what experiments they were performing. However, they asked us to customize our standard vacuum chamber.

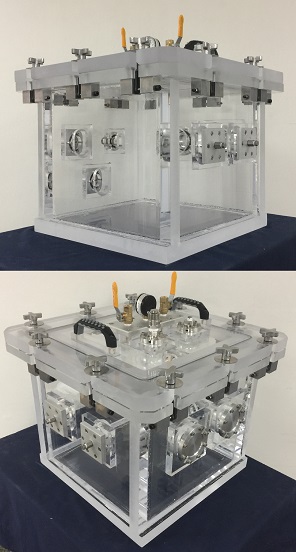

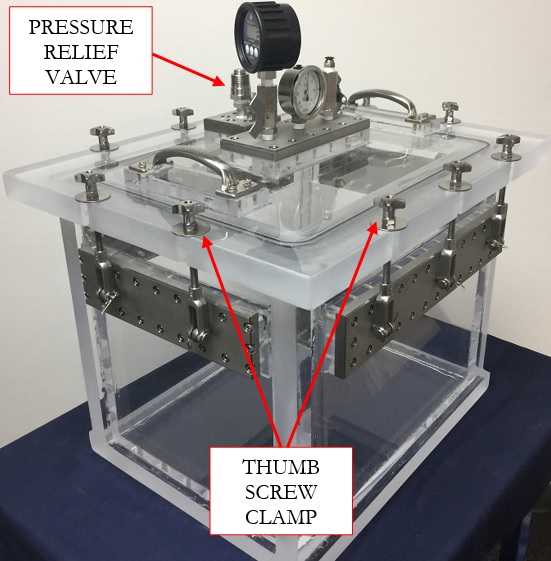

What you are looking at is our vacuum chamber that has a 5 psi pressure option with a 10 psi safety relief valve which will pop open if the pressure exceeds more than 10 psi (gauge pressure) inside the chamber. The chamber dimensions are 14 inch cube. In order to modify our acrylic vacuum chamber to be able to withstand a max of 10 psi overpressure, we had to install thumb screws that would hold the lid compressed against the O-Ring in order to keep an air tight seal.

In addition to the overpressure option, we also added two NW50 / KF50 Vacuum Ports on the rear wall. These vacuum ports are blanked off by an aluminum blank and a NW50 centering ring. This blank was removed and our client installed their own NW50 connection to their ports. On the Right wall we provided our client with two tube liquid or gas feedthroughs for the 1/4 inch tube OD. These liquid/gas vacuum feedthroughs will allow our client to run liquid or gas into the vacuum chamber without compromising the vacuum. On the Left wall, we added two gas or liquid vacuum feedthroughs for the 1/8 inch tube Outside Diameter. Also, on the left wall is a 1/2 NPT female port that was blanked off with a plug and later used by our customer to add temperature measuring device into their vacuum chamber.

Are you an aerospace company that is looking to get a vacuum system? We have worked with all major US aerospace companies such as NASA, Boeing, and Northrop Grumman. Contact us to see why such amazing companies chose to work with us.

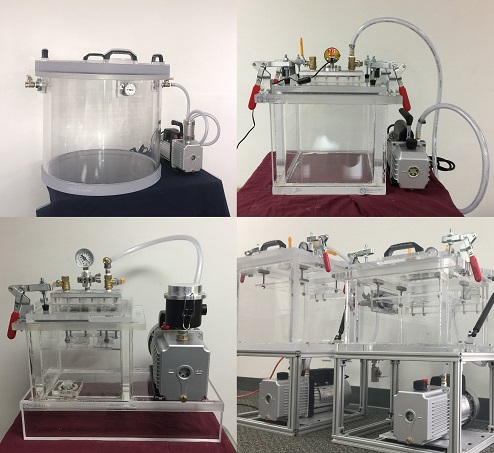

Some of our Popular Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers