Case studies demonstrating our expertise in vacuum systems design and manufacturing

Vacuum Extrusion

A car part manufacturer consistently experienced a problem with regards to their vacuum extrusion unit. Their vacuum extrusion chamber unit was leaking; hence they were not able to properly outgas their product. They went through several local job shops until they ultimately contacted us because they were urgently looking for ways to decrease the absolute pressure inside their vacuum extruder. SANATRON accessed the situation, designed, and built a new vacuum extrusion chamber that has worked very nicely ever since (4 years and going strong)Hi Pot Discharge Testing

An aerospace supplier ran into trouble when their contractor fell through on delivering Hi-Pot cables. Our client was promised that their Hi-Pot cables would be thoroughly tested before delivery by their vendor. Well, delivery time came and their vendor was unable to design a high altitude testing system. Our client was stuck with hundreds of thousands worth of untested Hi-Pot cables. They ultimately found SANATRON who because we have the experience to design an altitude test unit capable of testing Hi-Pot cables with complex geometry.

Aerospace and Satellites Test System

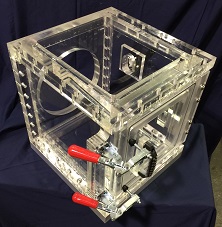

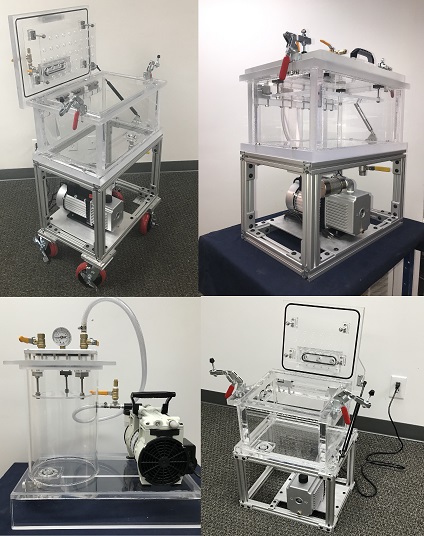

This client found SANATRON after someone else failed to build a robust acrylic vacuum chamber. After just several cycles, the walls gave out and separated creating a leak, not to mention a safety risk. SANATRON was able to deliver a more robust vacuum chamber because of many years of design experience and quality manufacturing. Our acrylic walls are interlocked and bonded with an acrylic adhesive made from a mixture that is a trade secret. The risk of wall separation, beveling, and leakage are effectively eliminated.

You may be interested in some of our other items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers