Have you ever wondered how the weather forecast works? You must admit; the weathermen (or weatherwoman) have become a whole lot more accurate over time. 10 years ago, the weather forecast was not as accurate as it is today.

Part of the reason is that we have better forecasting technology as in more powerful computers who crunch numbers faster to out a most likely scenario. Another reason is that mathematics, physics, and science has progressed. The main reason however, is that we have better tools and equipment.

Did you know that there are countless large weather stations spread across the US that continuously measure and record temperature, moisture, wind speed, barometric pressure, etc. Over the years, I have done a lot of trail running and have passed countless of these weather stations and never bothered to ask myself what these fenced off structures were spread all across the Wasatch Front. It all changed one day when we received a call from one of the engineers who maintains and calibrates the sensors of weather stations.

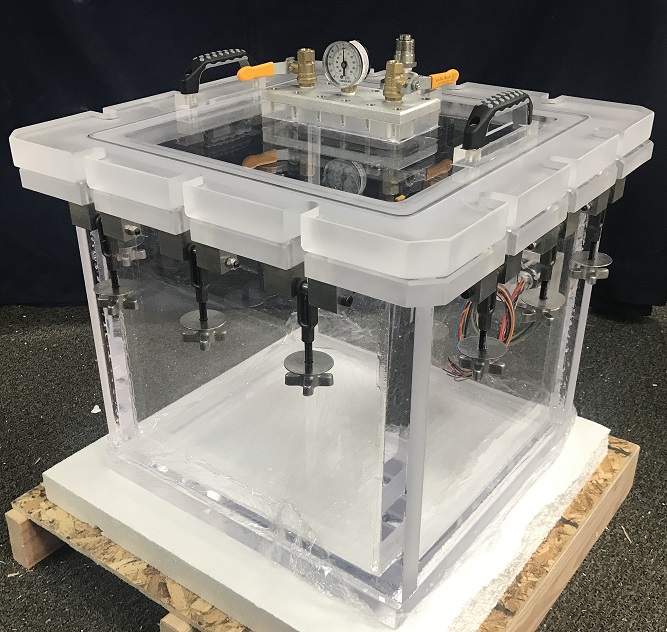

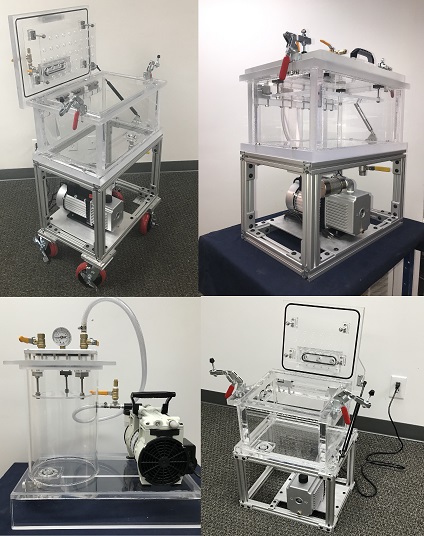

The requirements were simple, build a pressure and vacuum chamber with several vacuum feedthrough wires so that the calibration engineer has the ability to connect to the sensors inside the vacuum chamber during the vacuum run without compromising the vacuum. The overpressure is required because the sensors are calibrated from sea level to 30,000 feet. At higher altitudes, additional pressure must be applied to simulate atmospheric pressure present at sea level.

Clear Acrylic Vacuum Chambers turned out to be a good choice because the walls are transparent enabling full view of chamber interior during calibration. In addition to being fully transparent, acrylic vacuum chambers are easily modified which means that several vacuum feedthroughs can be added to the vacuum chamber with relative ease.

If you would like to find out more about how to get a similar vacuum chamber, fell free to Contact Us

Similar Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers