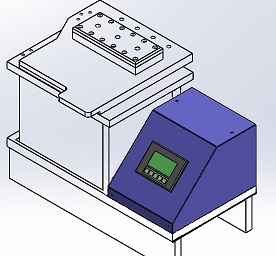

Force Decay Leak Testing Systems

Force Decay Leak Testing is a very popular quantitative leak testing method used to quality test package and product integrity due to its ability to detect small leaks which cannot be seen through visual inspection. In this method, the test specimen is internally inflated by either internal pressurization or vacuum force. The inflated test specimen will, in turn, apply a force on a pressure transducer. Finally, the change in force applied by the inflated specimen over a specified time is observed.

As you can see, the force decay leak testing system offers the best of both worlds when it comes to decay leak testing since the specimen can either be internally pressurized through an external pressure source or a pressure differential can be created by a way of vacuum. Another advantage of the force decay leak test is that it does have the ability to locate a leak. However, locating a leak is dependent on how the experiment is setup.

Why would a force decay leak testing method used over pressure decay or vacuum decay? There are several reasons; consider a pharmaceutical blister packs. A blister pack cannot be internally pressurized. A blister pack is also not suitable for vacuum decay since the volume of a single pill chamber is not large enough to hold significant amount of air. On the other hand, if this blister pack is placed into a fixture, and vacuum is applied, the fully sealed packs will extent and apply force to the pressure transducer of the force decay leak tester. If there is a gross leak, no force will be applied, if there is a micro leak, a drop is force will be recorded. Therefore a force decay leak tester is an ideal solution in situations where air volume is small, or where the specimen is semi-rigid, or where there are no ways to internally pressurize the sample.

Common applications include but are not limited to quality testing of:

Blister Packs ■ Membranes ■ IV Bags ■ Test Pouches ■ Masks ■ Bulletproof Vests ■ Food Trays ■ Heat Sealed Pouches ■ Fully Enclosed Containers ■ Water Proof Electronics ■ IP67 ■ Medical Equipment ■ Medical Seals ■ Sealed Containers

Quick Facts

10-3 sccm

Possible – depending on setup

YES

N/A

NO - must be customized to specimen