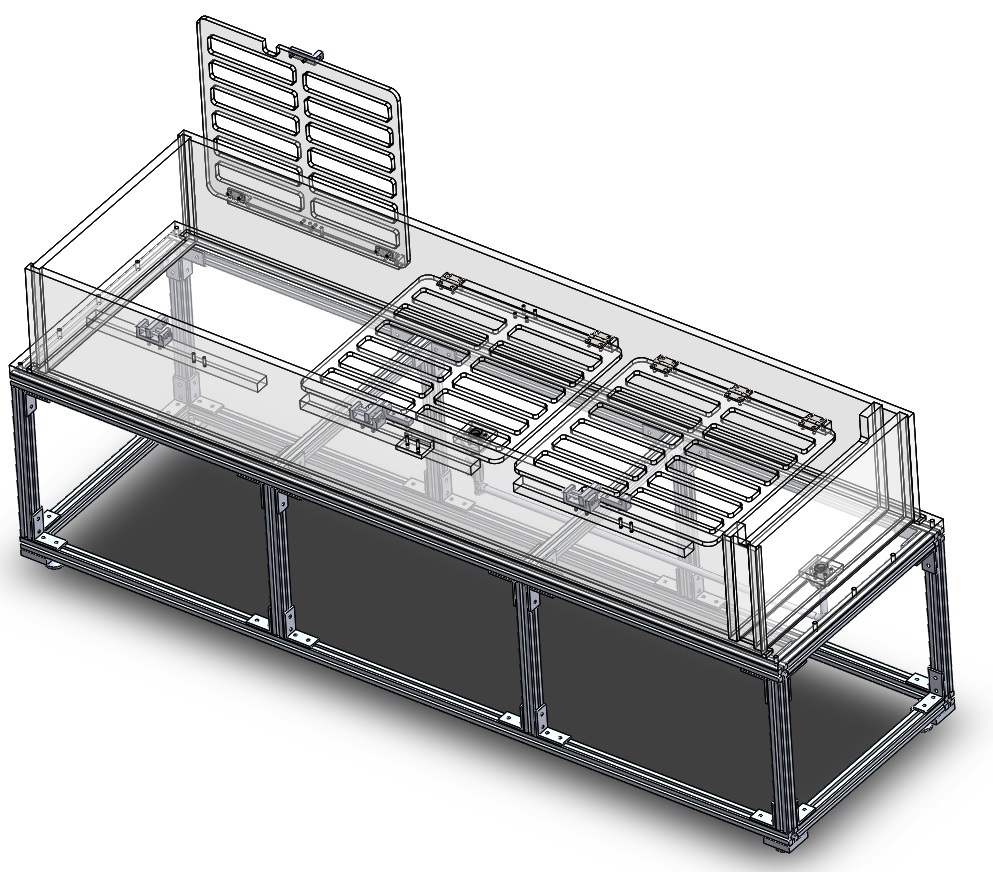

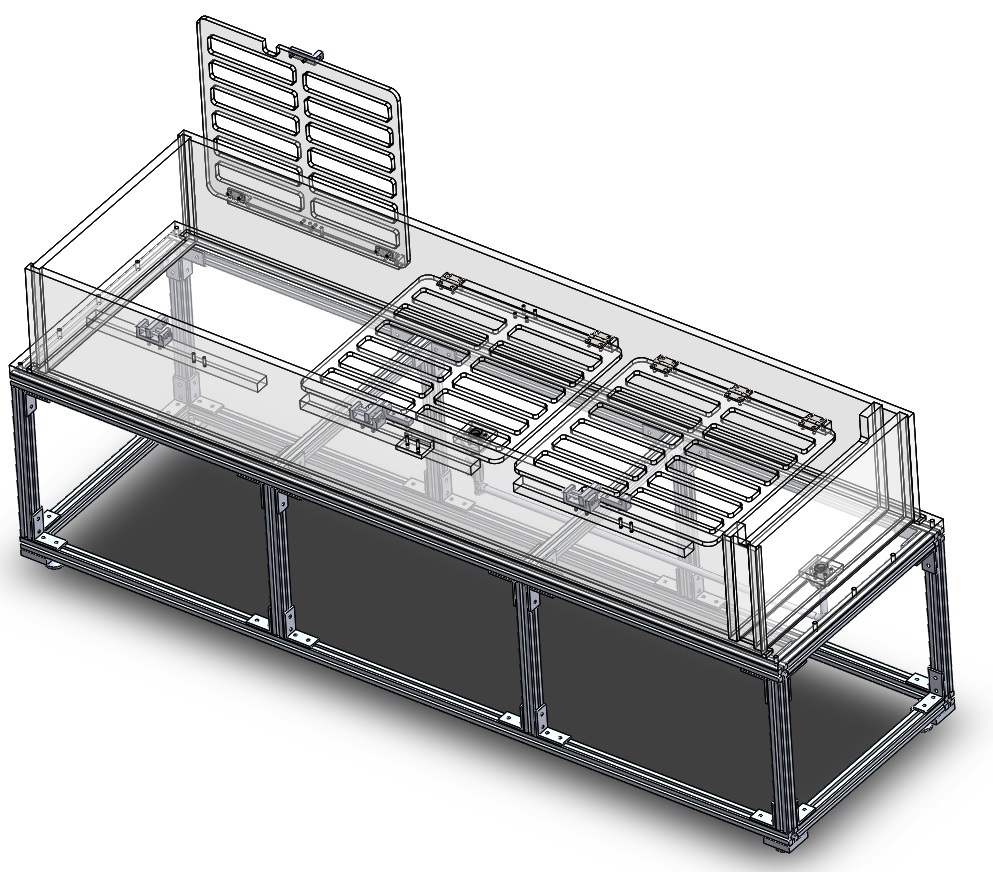

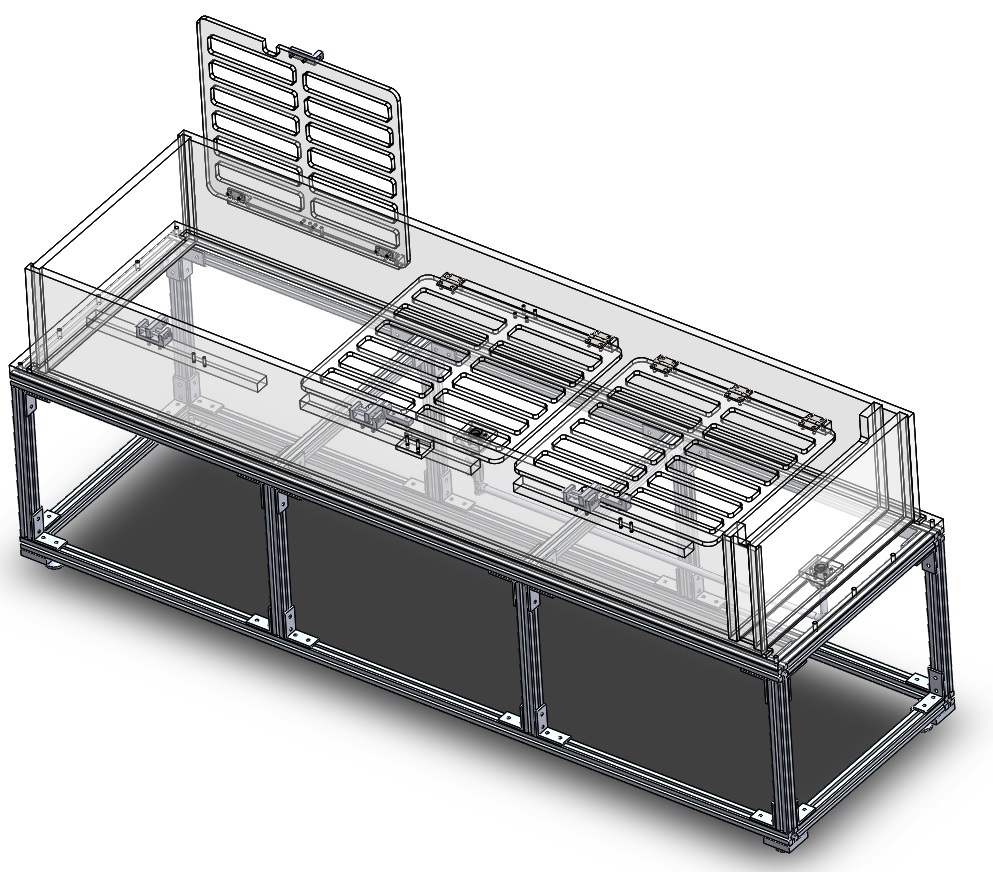

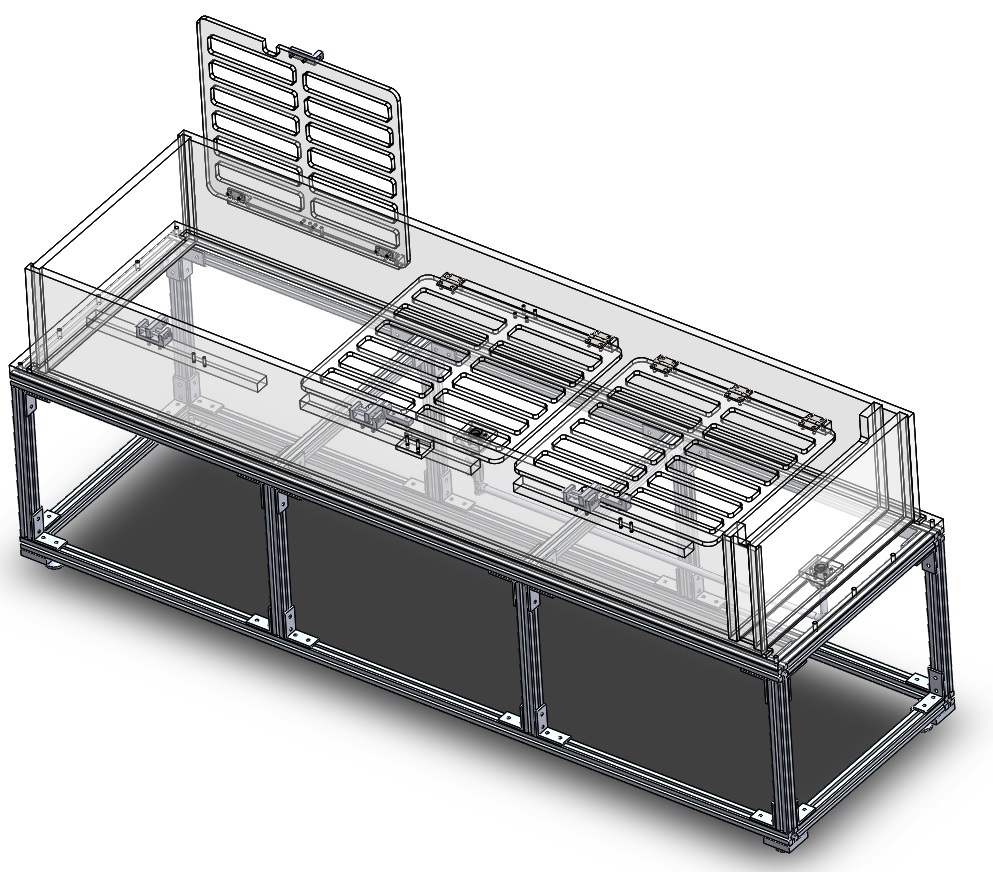

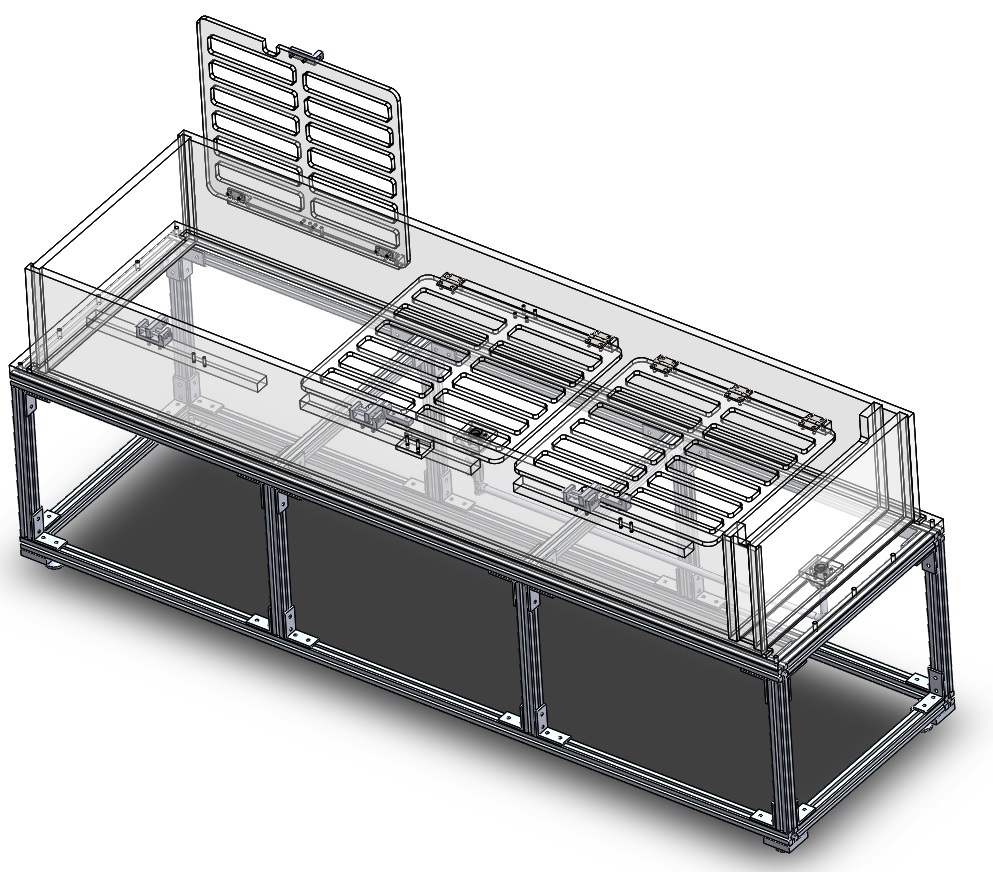

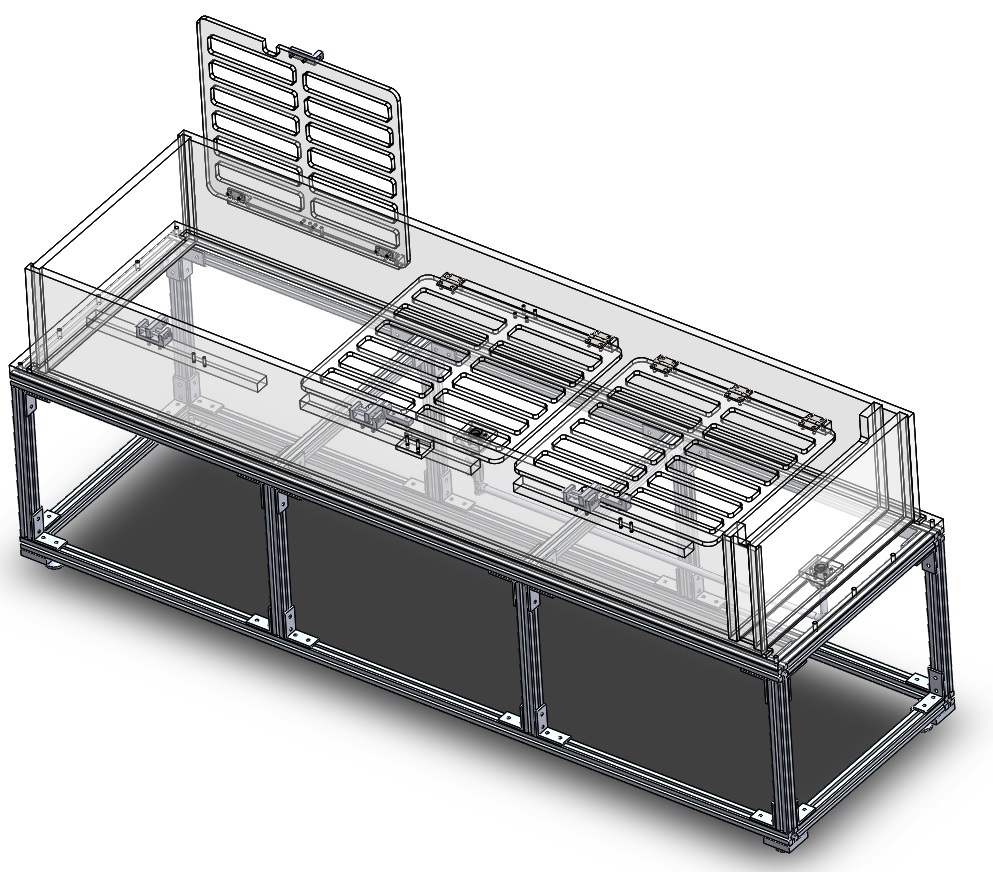

Internal Pressurization ASTM F2096 Leak Testing Systems

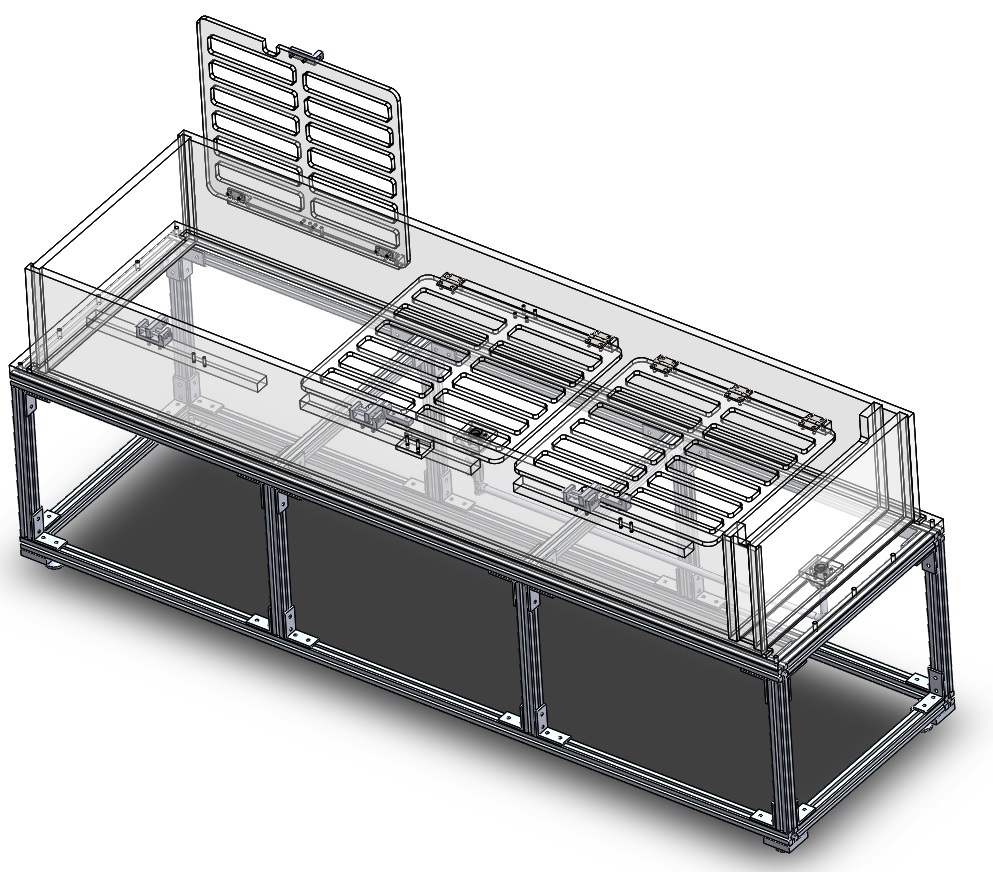

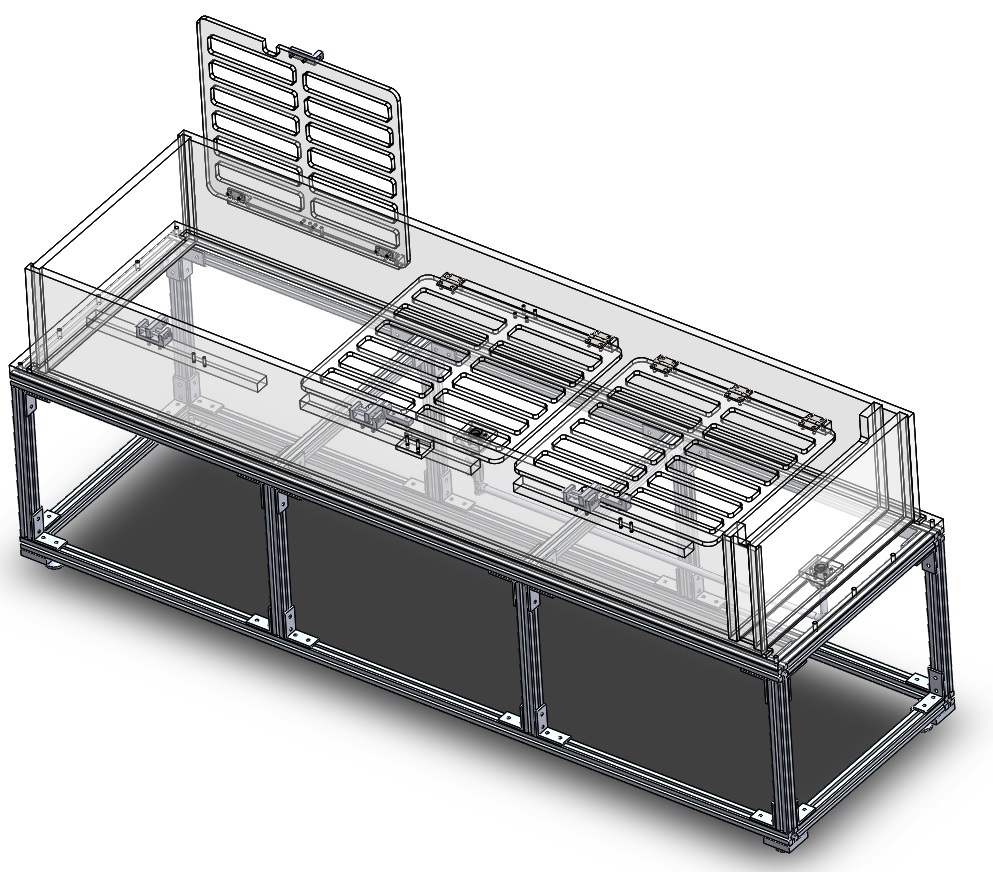

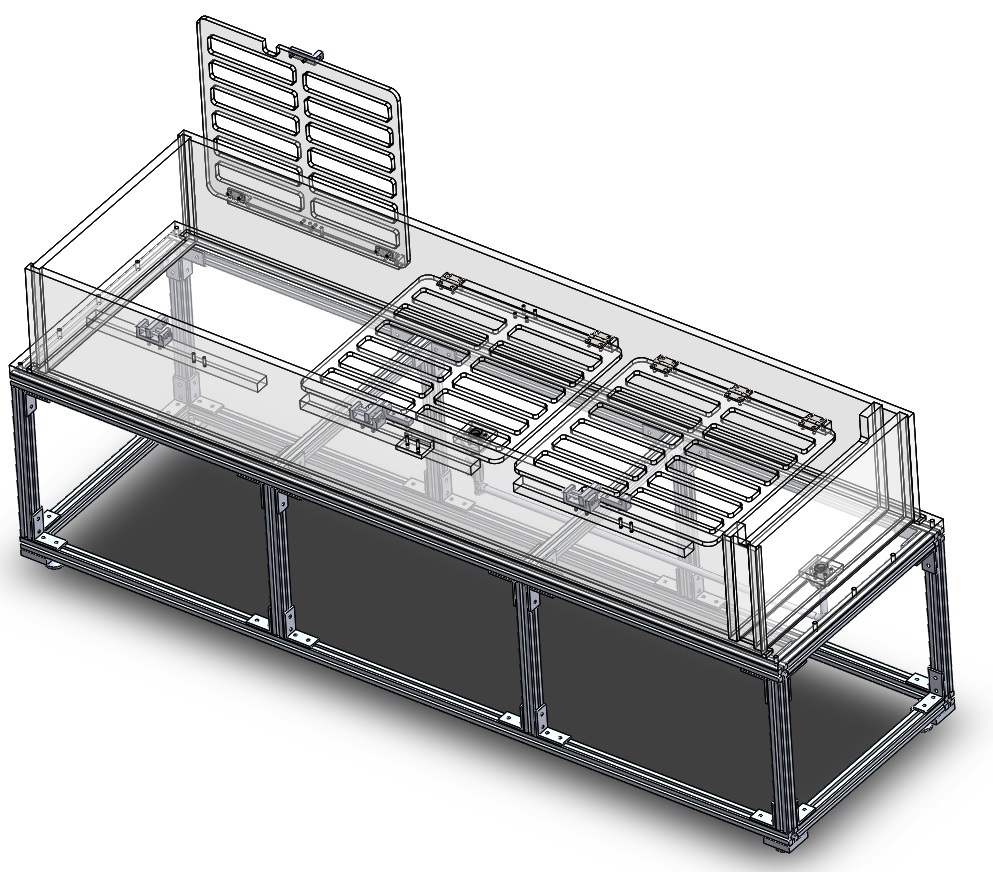

This Internal Pressurization Tank System is designed to Detect Gross Leaks in Packaging by Internal Pressurization of test samples – Also known as a “Bubble Test”. It is built to meet or exceed the specifications set forth in the testing procedure ASTM F2096 – 11. The Sensitivity of this test method is 250 micro meters (0.010 in) hole diameter. The probability of bubble detection emitting from a hole that is 250 micro meters (0.010 in) is 81%. Keep in mind that this System has not been evaluated for porous materials. The examination specimen for this testing procedure can be, including, but not limited to: Pouches, Trays, Boxes, Bottles, Bags, Pockets, Purses, Receptacles, Sacks, Plates, Jars, Jugs, Vials or anything else that can be punctured by the testing probe, submersed under water, and pressurized with air.

The advantages of this test method are that this is a very practical leak test that delivers immense value fast by giving you the test results you need within 30 seconds or less. Another advantage of Bubble testing your packages is that the leak can be identified and located rapidly allowing you to spot patterns or inconsistencies during your testing. This System is extremely useful in a laboratory environment where uncommon or diversely shaped and sized specimen are tested. Moreover, long or oddly shaped packages can be easily tested with this system too. This testing methodology is perhaps the simplest way to evaluate package integrity of sealed packages where contamination free, sterile, or air-tight seal is of uttermost importance. Finally, no special conditioning or sample preparation is required - meaning that you can complete your package integrity test within a very short timeframe.

This internal Pressurization Leak Testing System is an open tank, water immersion leak testing system. If you are looking for a vacuum bubble leak testing system, please click here: . A reason you would want to use an internal pressurization leak testing system over a vacuum leak testing system is if you have a small volume pouch or specimen that would make it very difficult to detect air emission. Another reason for using this system is if your specimen is porous. Yet, another reason to use this over a vacuum bubble leak testing system is that you can increase your specimen internal pressure up to 500 psi (a vacuum leak testing system is limited by a 15 psi pressure differential.)

Quick Facts

10-3 sccm

YES

NO

ASTM F2096

YES - just add water!

This is an internal pressurization bubble testing system that is designed specifically to enable you...More Info

This is an internal pressurization bubble testing system that is designed specifically to enable you...More Info

This is an internal pressurization bubble testing system that is designed specifically to enable you...More Info

This is an internal pressurization bubble testing system that is designed specifically to enable you...More Info

This is an internal pressurization bubble testing system that is designed specifically to enable you...More Info

This is an internal pressurization bubble testing system that is designed specifically to enable you...More Info

This is an internal pressurization bubble testing system that is designed specifically to enable you...More Info

This is an internal pressurization bubble testing system that is designed specifically to enable you...More Info

This is an internal pressurization bubble testing system that is designed specifically to enable you...More Info