High Altitude Vacuum Testing of Electrical Connectors and Components

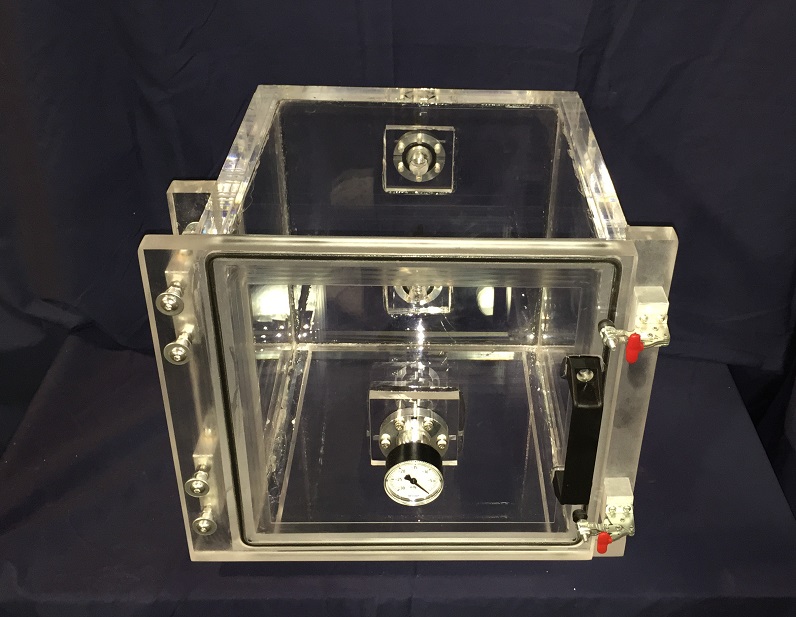

This was an interesting project where one of our customers needed to test wires up to 44 inches long within a high altitude simulation environment. In addition to testing wires, several other electric connectors required altitude testing as well. The altitude requirements were 100,000 feet (30.510 km) which corresponds to 8.36 Torr - a piece of cake when it comes to the vacuum requirements of our chambers.

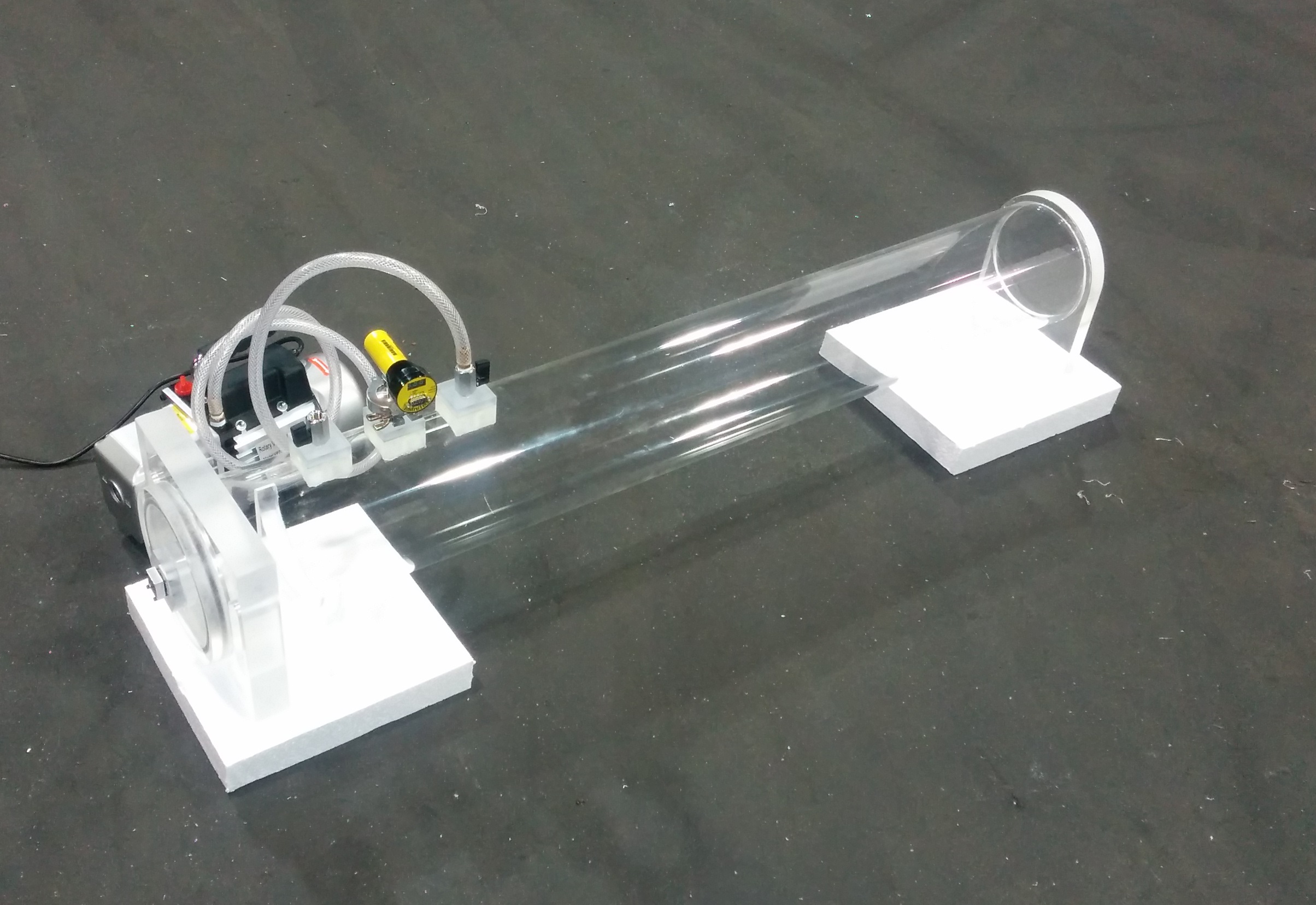

We would like to take a moment and bash our competitors on this one and point out where they went wrong: Our competitors have sales people and not engineers communicate with their customers when it comes to understanding customers design requirements. This leads to suggesting over-engineered solutions of humongous projects, prices, and lead times. When this customers came to us to, our question to them was simple: "What exactly are you trying to accomplish and what are the exact dimensions of the part you were testing?" This enabled us suggest a chamber which was 52 inch long and about 6 inch in diameter with a custom designed lid. Our quote blew our competitors away because 1. their sales staff had no idea what the customers goals were and 2. they were over-engineering, hence overcomplicating a simple problem.

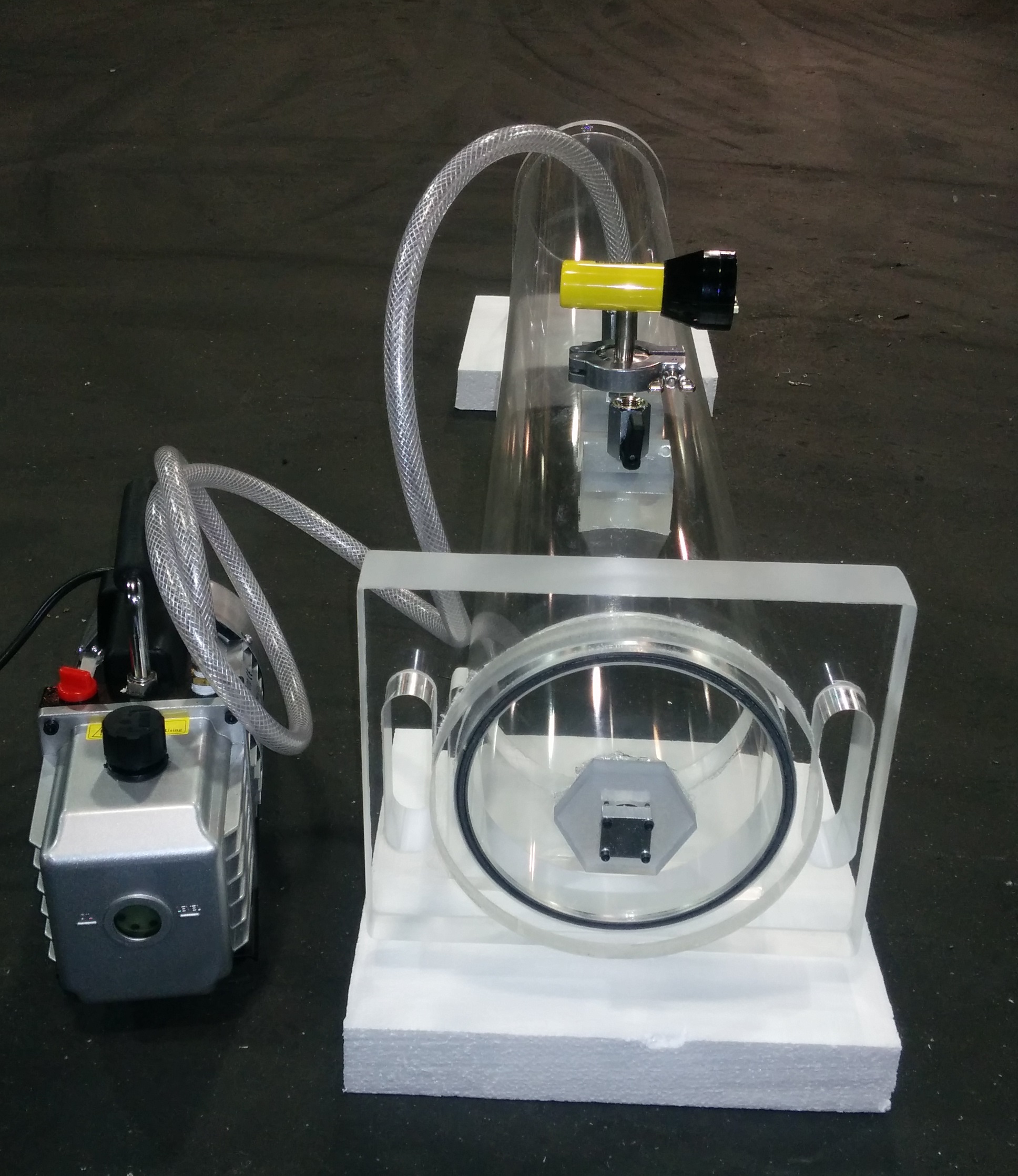

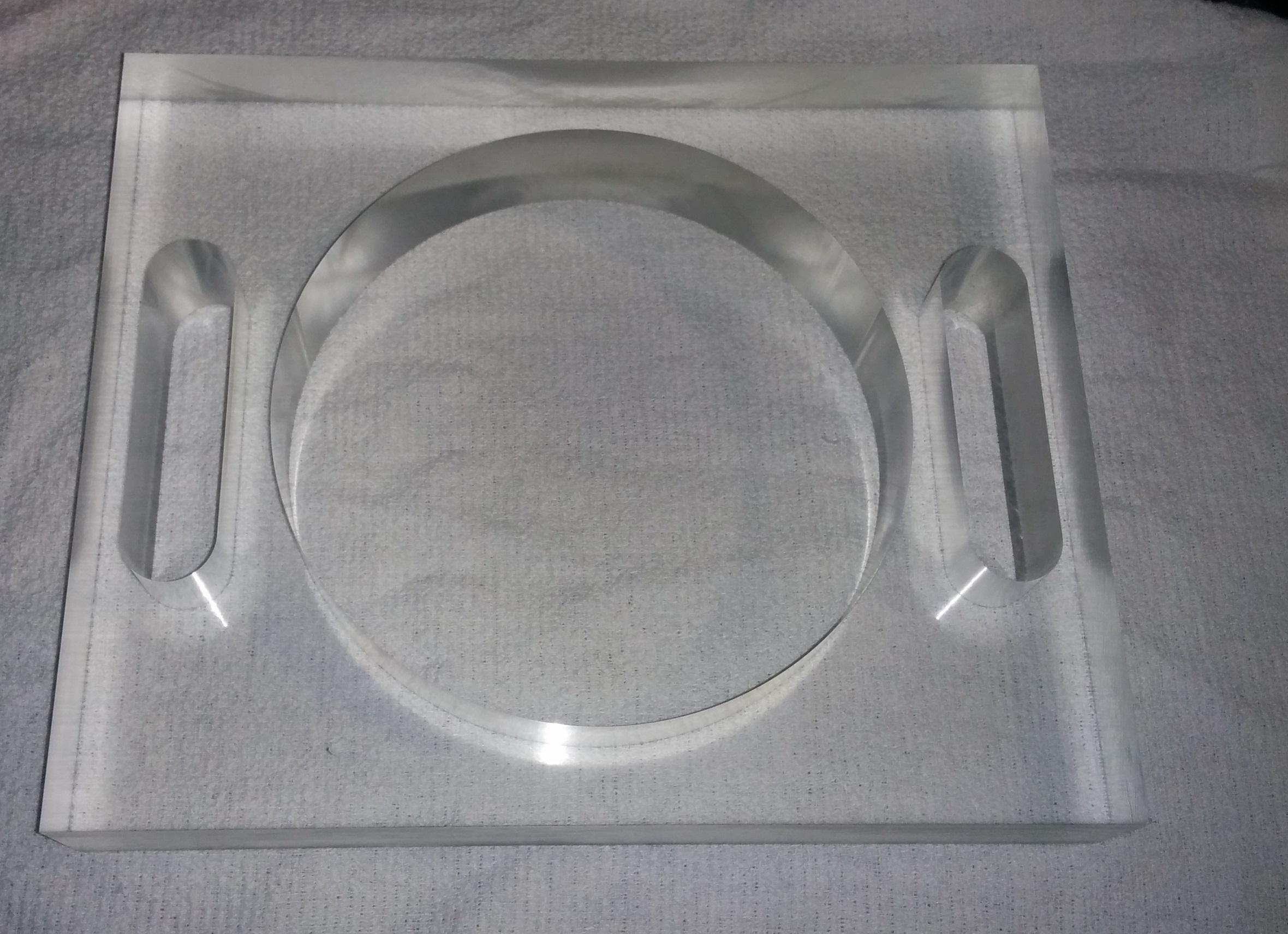

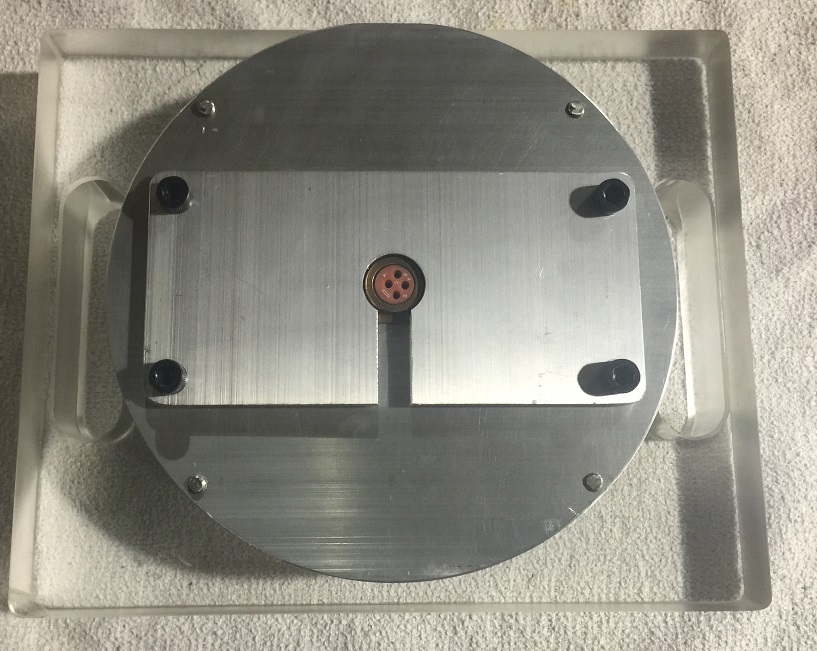

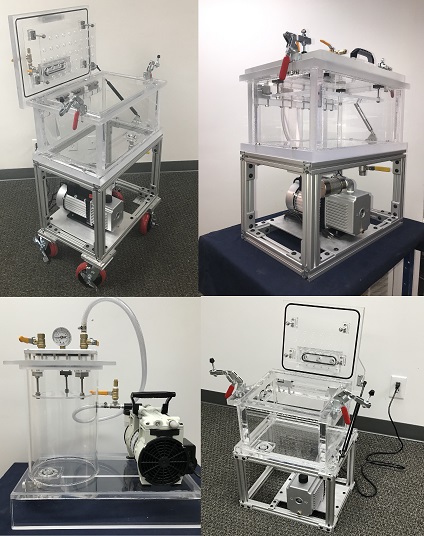

What you see here is a:

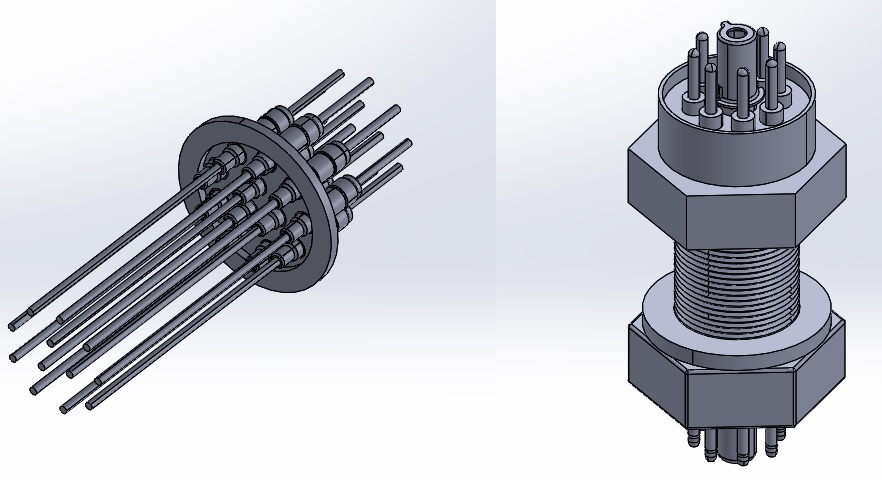

1. custom vacuum chamber which allows for plenty of space for electronic wires and widgets to be tested at high altitude.

2. A custom design vacuum chamber Lid which allows for flexible electronic connector changes enabling fast and reliable high altitude electronic equipment testing.

WAIT! Take a look at similar Items you may like…

Our clients prefer to work with us because we are Experts in Custom Fabrication (especially Polymer Fabrication). There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers