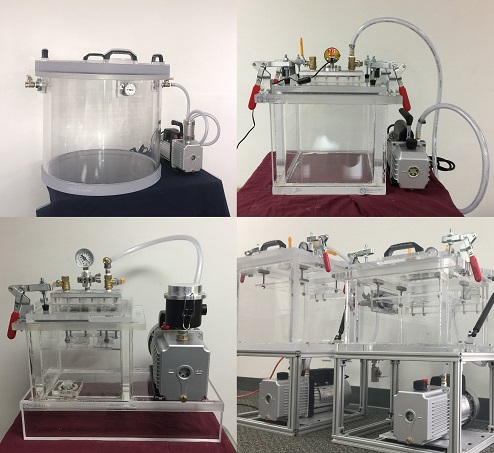

Acrylic vacuum chambers provide unparalleled versatility and customization, making them an ideal choice for a wide range of industrial, scientific, and research applications. One of their key advantages is the ability to integrate specialized components and modifications to suit precise operational needs.

At Team Sanatron, we have worked extensively with diverse industries, designing and engineering custom vacuum solutions tailored to rough-to-medium vacuum applications. Our expertise spans the development of turnkey systems that accommodate complex requirements, ensuring optimal performance, durability, and efficiency.

With acrylic vacuum chambers, the possibilities for customization are virtually limitless. From integrated sensors, feedthroughs, and automated controls to specialized coatings and structural reinforcements, we can incorporate nearly any feature to enhance functionality and meet stringent operational demands.

There is another website that shows more examples on how a vacuum chamber can be customized. Click here to see more Clear Acrylic Vacuum Chamber Custom Options

DO NOT MAKE Modifications

to your chamber without written approval from Sanatron

Purchase Our Acrylic Vacuum Chambers Here

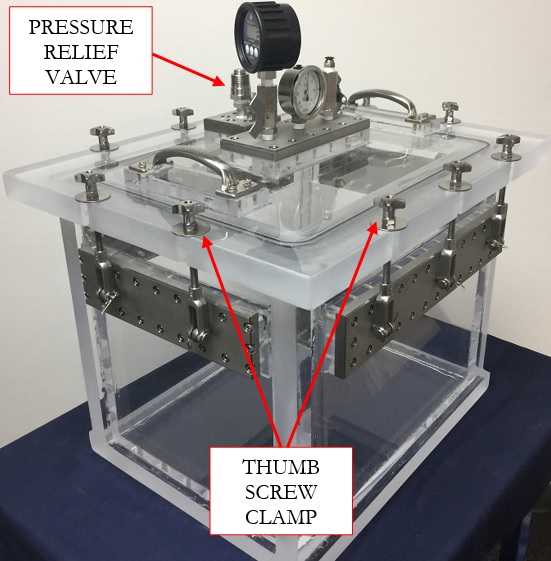

Over-Pressurization Option, Enhanced Versatility and Robust Safety

Our Acrylic Pressure Chambers are engineered for both vacuum and overpressure applications, offering exceptional adaptability across various industries. Designed with precision and structural integrity, these chambers can be pressurized to 5 psig, 10 psig, and 15 psig, expanding their functionality beyond standard vacuum operations.

To ensure robust safety and reliability, each over-pressurization configuration includes a vacuum-rated pressure relief valve, which is meticulously calibrated to activate at the rated pressure of 15 PSIG Max. This critical safeguard prevents excessive internal pressure buildup, effectively venting excess force to maintain system stability and operator safety.

Implementing the Over-Pressurization Option requires strategic modifications to the chamber’s design, including additional reinforcements and high-precision components. Every Acrylic Pressure Chamber in this configuration is equipped with multiple high-strength thumb screws, which must be securely tightened before pressurization. Proper sealing is paramount—ensuring that the O-ring is fully compressed minimizes leakage risks and maintains chamber integrity under elevated pressures.

For optimal performance and safety, always verify that all fastening mechanisms are properly engaged and that the integrated pressure relief valve is operational before initiating pressurization procedures. This meticulous approach guarantees a durable, high-performance system built to withstand the demands of both vacuum and pressure applications.

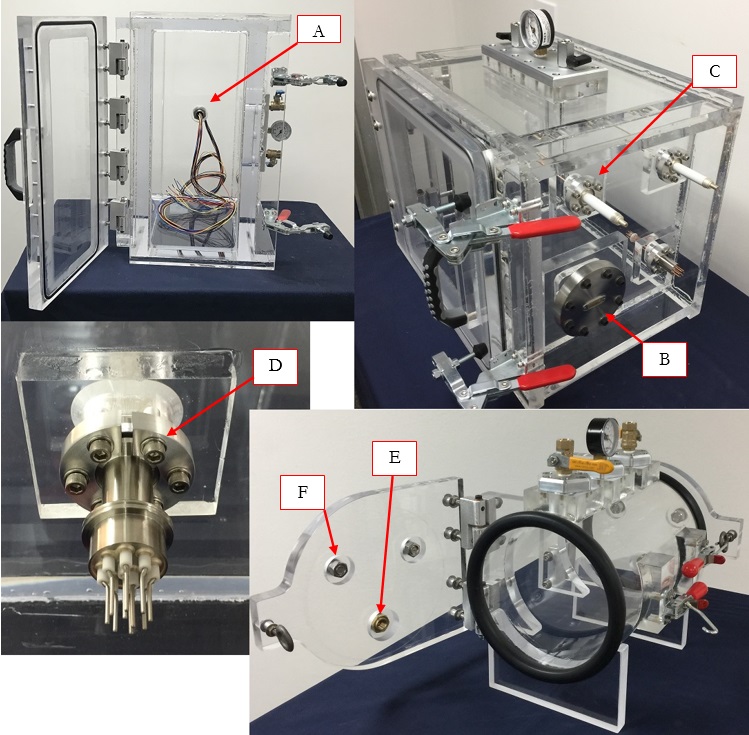

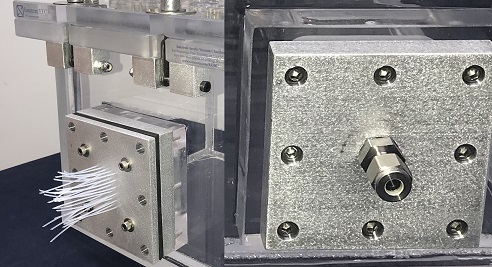

Electrical and Liquid Vacuum Feedthrough

Electrical Power, Data, Thermocouples, and other Electrical Signals can be installed on your acrylic vacuum chamber. Please see the images below to see some application examples

B. Data Vacuum Feedthrough such as: D-SUB (Subminiature D), USB, and Ethernet

C. High Amperage and High Voltage Vacuum Feedthrough

D. Thermocouple Vacuum Feedthrough

F. Pneumatic Vacuum Feedthrough

Wobble Sticks and Physical Actuators

We offer a large selection of Vacuum Wobble Stick and Physical Manipulators. These manipulators will enable you to move, rotate, and translate your specimen or objects inside your vacuum chamber while the vacuum chamber is under vacuum.

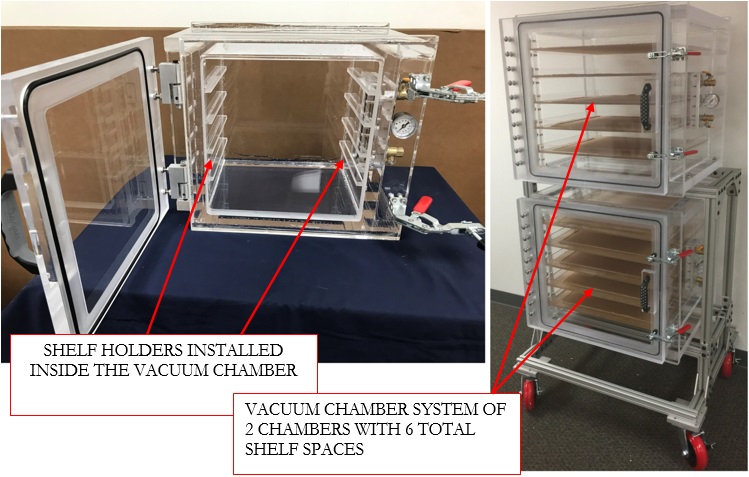

Shelving Solutions, Maximize Usability and Internal Space

Our Vacuum Chambers are engineered for maximum adaptability, allowing for seamless integration of additional shelving to enhance functionality and spatial efficiency. Each chamber can be retrofitted to accommodate multiple shelves, optimizing internal organization while maintaining structural integrity and vacuum performance.

Designed to increase usability and space, our shelving solutions can be tailored to your specific requirements. Whether you require precision-fabricated vacuum-rated shelves or prefer to use your own, we provide expertly installed shelf support systems that ensure effortless integration. Each shelf holder is strategically positioned to facilitate smooth insertion and removal while preserving the chamber’s operational reliability.

This modular shelving enhancement expands the chamber’s versatility, enabling multi-tiered processing and improved workflow efficiency within a high-performance Vacuum Chamber. Built for precision, durability, and customization, our chambers deliver an unparalleled combination of usability and optimized space management.

Here are some more examples on Adding Shelves to your Chamber

Purchase Our Acrylic Vacuum Chambers Here

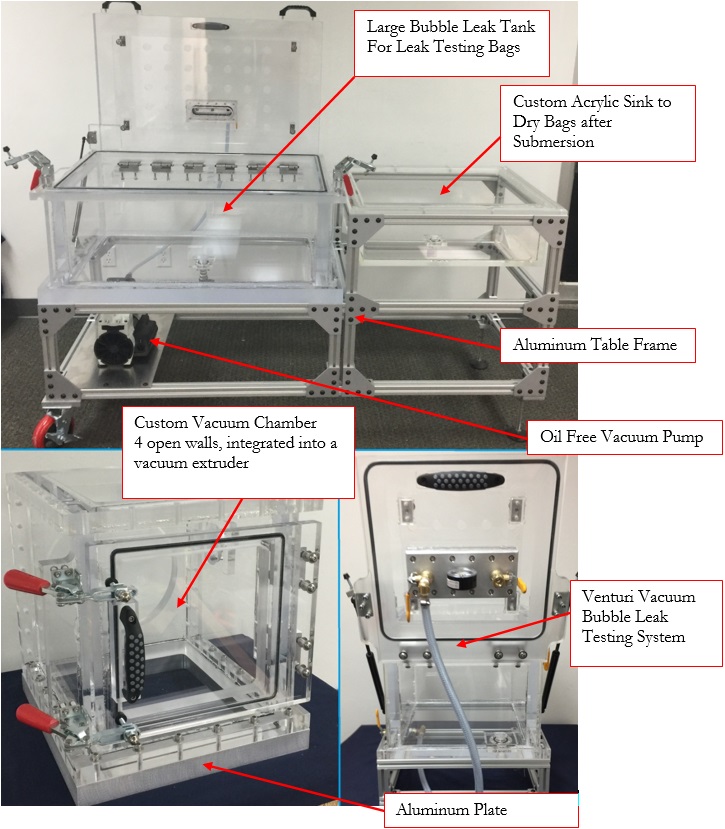

System Integration and Turnkey Solutions

Our vacuum chambers can be integrated and retrofitted into any system conceivable. You can either add our acrylic vacuum chamber to any of your systems or you can make the acrylic vacuum chamber a part of a complete turkey solution.

Check out a few examples on some of the work we did for our clients

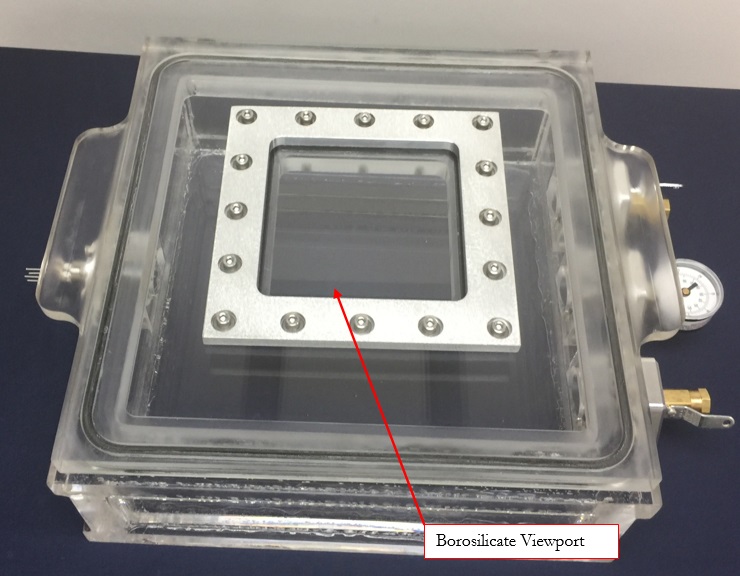

Precision Engineered Viewports for Enhanced Optical Performance

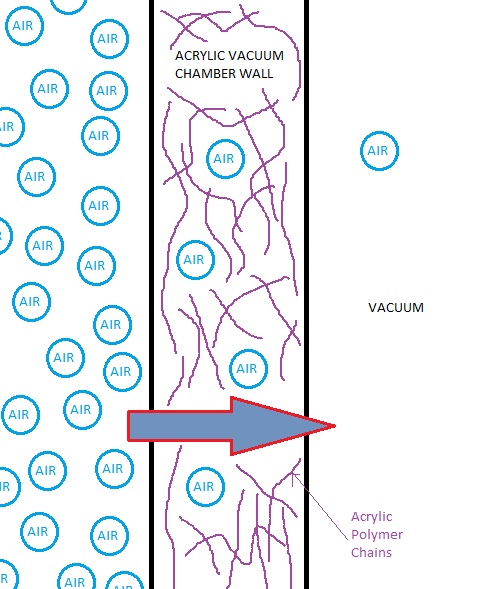

While acrylic provides excellent clarity for many applications, its transmission properties limit the passage of certain light frequencies, such as ultraviolet (UV) light, making it unsuitable for specialized optical applications. In industries requiring a broader light spectrum transmission, such as laser testing, solar power research, and photonics, integrating a high-performance Vacuum Viewport is essential.

Acrylic may appear transparent to the human eye, but it does not facilitate full-spectrum electromagnetic transmission. To overcome this limitation, we offer custom Vacuum Chamber Viewports engineered from a range of high-quality optical materials, including borosilicate glass, fused quartz, sapphire, and zinc sulfide glass. These excellent-quality viewports ensure optimal light transmission, precision control, and enhanced performance for demanding scientific and industrial applications.

Designed with precision and durability, our custom vacuum chamber viewports provide superior optical clarity while maintaining the structural integrity and vacuum performance of your system. Whether for high-energy laser experiments, spectroscopy, or advanced optical research, our tailored solutions deliver uncompromising quality and performance.

Vacuum Chamber with Heat Plates

There are instances where a heat plate must be placed into the chamber to heat up the specimen or part subjected onto a vacuum environment. Such applications include micro-fluidic experiments, vacuum heat sealing, and out-gassing, to name a few. A heat insulating plate is installed at the bottom with an electrical plug to power up the heat plate.

Purchase Our Acrylic Vacuum Chambers Here

WAIT! Take a look at similar Items you may like…

We make Robustly Designed and Quality Engineered Systems. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers