Top 5 Leak Testing Methods and Techniques Everyone Must Know

Leak Testing in Modern Manufacturing: Your Comprehensive Guide to Staying Ahead in Quality Control

Leak and Quality testing has never been more critical. Many industries such as automotive, aerospace, medical device, consumer electronics, food, R&D, and general manufacturing depend on precise, reliable leak testing methodologies to ensure seal integrity, product quality, and customer safety. As global supply chains grow increasingly complex, the margin for error gets smaller. Manufacturers, therefore, require the newest, efficient, and robust leak testing strategies to remain competitive.

This article offers a completely fresh perspective on the core principles of leak testing, along with new insights and modern best practices to help you stay updated and ahead. Whether you are an industry veteran, a quality engineer, or simply a curious reader, you will find valuable guidance on improving your processes, avoiding pitfalls, and ensuring excellence in manufacturing quality control.

Why Leak Testing Matters

Leak testing might sound like a niche procedure, but it is indispensable in every process which aims to maintain rigorous standards for product performance, safety, and compliance. Proper leak testing can prevent a range of complications, including product malfunctions, costly recalls, environmental damage, or customer hazards.

In the era of intense regulatory scrutiny and consumer vigilance, it is no longer sufficient to rely on outdated methods or inconsistent practices. Instead, companies must adopt strategies that accurately detect leaks in various conditions, from micro cracks in sealed medical devices to larger breaches in automotive fuel systems.

Advanced leak detection also brings extra benefits that go beyond simple PASS/FAIL outcomes. By systematically collecting and analyzing data, organizations can uncover deeper insights into process stability, material integrity, and production line efficiency. This will in turn enable proactive decision making and fosters a culture of continuous improvement.

If you understand how to apply the right leak testing technique, whether that may be Pressure Decay Testing, Vacuum Decay Testing, or another form of Non-Destructive Testing (NDT), or even a destructive leak testing method, you will be able to extend product lifecycles, improve brand reputation, and set higher benchmarks for overall manufacturing quality control and hence greatly improve long term profitability.

A Thorough Exploration of Top Leak Testing Methods

Modern leak testing has evolved considerably from the simple days of submerging a component in water and watching for bubbles. While Dunk Testing (Bubble Leak Testing) still holds a place in certain scenarios, the technology landscape now offers a range of sophisticated tools and processes.

We will explore some key methodologies, discuss their pros and cons in an entirely new way, and explore how they fit into the broader ecosystem of manufacturing quality control. Throughout this write up, you will also find references to emerging trends and actionable best practices you can immediately apply.

Method 1: Dunk Testing and Bubble Testing

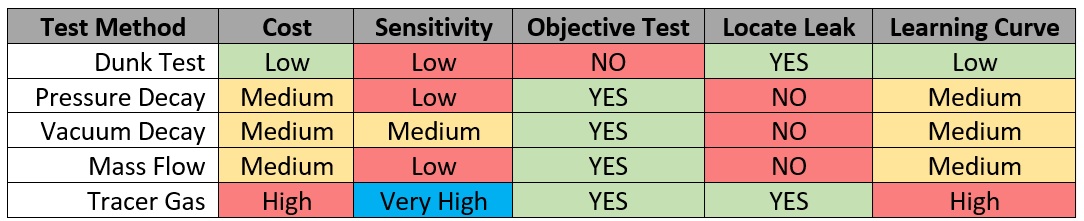

Dunk Testing, also known as Bubble Testing, has been a staple in leak detection for decades. Operators create a pressure differential (via internal pressure or vacuum), submerge test specimen in water, and visually watch for air bubbles that indicate leaks. While this approach may not offer the refined accuracy of methods like Helium Mass Spectrometry, it remains very cost effective, straightforward to implement, and fully capable of identifying gross leaks.

Dunk Testing is usually the first step as a dunk tester is fairly easy to setup, cost effective, and easy to use.

However, Dunk Testing has inherent limitations. It still relies heavily on the presence of a human operator. It is also inappropriate for components sensitive to water exposure or for situations requiring extremely tight leak thresholds that surpass the method’s detection capabilities. In short, Dunk Testing excels in basic, economic leak detection. Its modernization keeps it relevant, but for more advanced or sensitive products, organizations often need the precision of other methods.

Method 2: Pressure Decay Testing

Pressure Decay Testing remains among the most common forms of leak detection in manufacturing, largely due to its balance of simplicity, worthwhile, and accuracy. In this technique, an operator or automated system pressurizes a component, seals it off, and measures the change in internal pressure over time. A drop in pressure indicates a leak, which can be mathematically correlated to a specific flow rate. With recent advancements in sensor technology and data analytics, Pressure Decay Testing now achieves higher sensitivity than ever. Sophisticated controllers can factor in variations in environmental temperature, humidity, and even slight material deformations over time.

Many industries value this test for its quantitative results. Because the drop in pressure can be accurately converted to a volumetric leak rate, it facilitates compliance with standards that demand explicit numeric tolerances. Additionally, the testing cycle can be optimized for speed, making Pressure Decay Testing suitable for high volume production lines. However, one major drawback remains: this technique does not pinpoint the location of a leak, only confirms that one exists. Larger components requiring low leak thresholds also tend to yield smaller, more difficult to measure changes in pressure. Consequently, test durations may increase and productivity might be impacted.

Experts address some of these downsides by integrating Pressure Decay Testing with other leak detection methods, or by employing advanced calibration with a master part that quantifies leak rates within acceptable limits. In tandem with real time analytics, these strategies allow operators to flag anomalies quickly and intervene before defective products accumulate. Pressure Decay Testing thus remains a foundational approach, adaptable to many scenarios, yet still open to continuous improvement as technology evolves.

Method 3: Vacuum Decay Testing

Vacuum Decay Testing shares many characteristics with Pressure Decay Testing but inverts the pressure gradient. Rather than pressurizing a component, the system creates a vacuum inside (or outside) the Unit Under Test and measures how well that vacuum holds over time.

Vacuum Decay Testing is especially useful for applications involving enclosures that must remain sealed against external influences such as water, dust, or other contaminants. Medical equipment housings, underwater sensors, and outdoor electrical components commonly require this test to confirm resistance to external leaks

A key advantage of Vacuum Decay Testing is its resilience against environmental variables like temperature and humidity, which can impact test reliability when dealing with pressurized air. It’s also adept at detecting leaks that would otherwise remain unnoticed if the product only ever experiences external pressure differentials in its environment.

Another benefit is that it can complement Pressure Decay Testing by providing a more complete picture of a product’s leak integrity. On the downside, vacuum based techniques can be susceptible to internal moisture or evaporation. If a part contains small amounts of residual liquid, that liquid can evaporate under vacuum conditions, skewing the measured pressure changes.

Recent design enhancements include multistage vacuum profiles and outgassing controls that mitigate these issues, as well as advanced vacuum sensor arrays that deliver higher resolution readings. Such innovations allow Vacuum Decay Testing to integrate seamlessly into automated production lines that demand rapid, precise measurement. As manufacturing processes push toward smaller, more complex designs and lighter materials, vacuum testing solutions are likely to continue their ascent as a mainstream method.

Method 4: Mass Flow Testing and Functional Flow Testing

Mass Flow Testing has emerged as a standout approach when you need to measure not only leak integrity but also confirm functionality within fluid or airflow channels. In Mass Flow Testing or Functional Flow Testing, pressurized air enters a component, and the tester monitors the flow required to maintain a constant pressure.

If the measured flow exceeds acceptable thresholds, there is a leak. On the other hand, if the flow is abnormally low, an obstruction or blockage may exist. This attribute makes Mass Flow Testing especially valuable for manufacturers of medical tubing, automotive fuel lines, or any assembly with intricate internal pathways.

One significant advantage is that Mass Flow Testing is considered a form of Non-Destructive Testing (NDT), because it does not require destroying or altering the part. It can handle larger leaks relatively easily and does not rely on submersion in water or complex tracer gases.

However, the method struggles with detecting extremely small leaks. Sensitivity depends largely on the flow meter’s range and accuracy, as well as the stability of the pressurized air supply. Advances in digital flow meter technology are addressing some of these issues by offering improved measurement accuracy, while feedback loops in modern test controllers help maintain consistent test conditions.

Many manufacturing lines now employ Mass Flow Testing for both final product verification and in process checks. This integration allows engineers to rapidly identify blocked channels or excessive leakage early in the manufacturing cycle, reducing the waste of components that pass multiple steps before failing a final test.

Because it can deliver both leak integrity data and functional flow information, Mass Flow Testing is an excellent option in a variety of industries, making it one of the more flexible technologies in the modern testing portfolio.

Method 5: Tracer Gas Testing and Helium Leak Testing

Tracer Gas Testing, a broad category that includes methods like Sniff Leak Testing, Nitrogen Purge Leak Testing, Accumulation Leak Testing, and Helium Mass Spectrometry, stands at the cutting edge of leak detection.

These approaches introduce an inert or detectable gas, commonly helium, hydrogen, or nitrogen, into a component or system. Specialized sensors or mass spectrometers then analyze the surrounding atmosphere or the internal environment to identify the gas’s presence, thereby revealing leaks with very high precision.

Hard Vacuum Helium Mass Spectrometry, in particular, is favored for products requiring extremely tight leak thresholds, such as hermetically sealed electronic enclosures, high pressure fuel systems, or sensitive medical implants. By evacuating the air around the component and introducing helium, any escaping gas is detected by the mass spectrometer at trace levels.

This method offers superior sensitivity and can pinpoint even the smallest leaks, something that traditional Dunk Test, Pressure Decay, or Vacuum Decay Testing methods cannot achieve. Helium Leak testing is orders of magnitude more sensitive. Tracer gas techniques are also less affected by temperature fluctuations or atmospheric changes, making them ideal in uncontrolled or dynamic factory settings.

However, these methods involve a more complex test setup and higher equipment costs. Helium itself can be expensive, and certain tracer gas systems require specialized chambers or sniffer probes that add to capital expenses. Ongoing developments aim to tackle these drawbacks.

Helium recovery systems recapture and recycle gas to reduce operating costs, and advanced sniffers with real time feedback enable more efficient manual detection. For many precision applications in high stakes industries, such as aerospace or advanced medical devices, investing in Tracer Gas Testing pays off by significantly decreasing the risk of product failure in the field.

Selecting the Right Leak Testing Approach for Your Manufacturing Line

Choosing the best leak testing method for your products is a decision that depends on factors such as production volume, acceptable leak rate, part geometry, materials, and cost constraints.

A medical device manufacturer might favor Tracer Gas Testing for its ability to detect extremely small leaks that could compromise patient safety, whereas a high-volume automotive assembly line might rely on fast, efficient Pressure Decay Testing to keep up with daily throughput requirements. While a food manufacturing facility might go for the Dunk Leak Test for its simplicity and cost effectiveness. Mixed strategies are also common, where a broad, faster test like Mass Flow Testing is used as a preliminary screen, followed by a more targeted test like Helium Mass Spectrometry for borderline units.

In modern manufacturing quality control, combining different tests can yield better results than relying exclusively on one method. Companies typically start by defining the required leak rate threshold based on function and safety standards. They then conduct feasibility studies or pilot projects to compare the sensitivity, reliability, and cost effectiveness of various tests.

In parallel, there are often discussions with equipment vendors, testing labs, or internal research and development teams to configure the system precisely for unique product specifications.

Because no single technique is universally superior, the ideal solution often combines multiple methods and advanced analytics. For instance, a facility producing complex medical equipment might deploy Pressure Decay Testing for quick, routine checks and then run Helium Mass Spectrometry as a secondary check on a smaller percentage of units. Balancing time, budget, and accuracy demands a coordinated strategy, where each test aligns with the overall production workflow.

Elevate Your Leak Testing for a Resilient Future

Leak testing stands as a linchpin of modern manufacturing quality control, bridging the gap between product design and the reality of daily operation. Methods such as Dunk Testing, Pressure Decay Testing, Vacuum Decay Testing, Mass Flow Testing, and Tracer Gas Testing all play pivotal roles in ensuring products meet strict safety, regulatory, and performance requirements.

As this article has illustrated, these methods have undergone significant transformation, integrating new sensors, and various platforms, making them both more accessible and more powerful than ever.

The key takeaway is that successful leak testing is not merely about selecting the right equipment. It also involves understanding the intricacies of your product’s use cases, establishing defined leak rate criteria, and continuously reviewing your data to refine processes.

This holistic approach, bolstered by the latest insights in Helium Mass Spectrometry, Sniff Leak Testing, Nitrogen Purge Leak Testing, and Accumulation Leak Testing, positions manufacturers to anticipate and adapt to evolving market demands.

If you’re ready to optimize your leak testing processes, consider consulting with Sanatron, exploring the latest research in Non-Destructive Testing, or partnering with experienced professionals who can tailor a solution to your unique requirements. By doing so, you’ll not only meet today’s stringent quality standards but also future proof your operations against a competitive manufacturing landscape.

It’s an exciting time for leak testing, filled with possibilities to enhance reliability, efficiency, and overall product integrity in ways never before imagined. By adopting a strategic, technological, and forward perspective, you can ensure that your organization remains at the cutting edge of both innovation and excellence in manufacturing quality control.