Vacuum chambers are a great tool for the aerospace engineer because these enable her to simulate altitudes by converting it to absolute pressure. Another reason vacuum chambers are useful to the aerospace engineer is because a wide array of vacuum testing can be performed. A lot of these test are specific to the test protocol or the component to be tested. The test themselves are proprietary which is why sometimes we do not have a good handle on what exactly our clients are looking to do.

What we do know is that a vacuum chamber can be used to simulate Martian Atmospheres by purging the vacuum chamber and filling it up with the correct gas mixture. Mars atmosphere is mostly Carbon Dioxide with other trace gasses. The Martian atmospheric pressure is 5 Torr is more than 150 times thinner than Earth’s atmosphere.

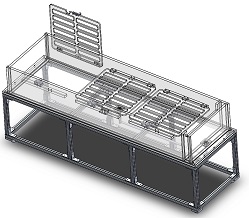

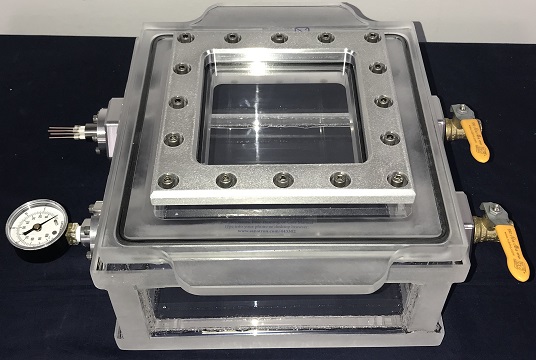

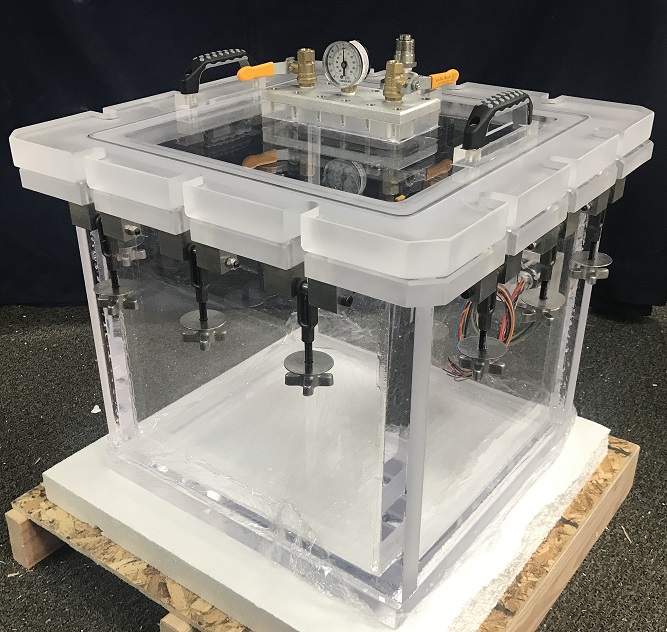

You are looking at a total of 4 Acrylic Vacuum Chambers, Front Loading, Hinged Side Door. There is one addition: an aluminum top access panel. This access panel is removable by removing the fasteners tied this panel down and compressing it to the O-Ring.

Are you working on complex aerospace applications?Contact Us and find out how we can help you build better vacuum systems.

WAIT! Take a look at similar Items you may like…

We make Robustly Designed and Quality Engineered Systems. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers