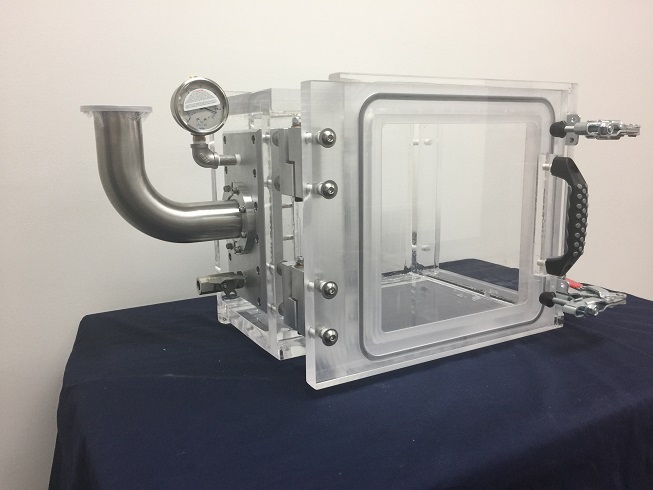

Did you know that canned food seam strength and integrity testing can be performed in an acrylic vacuum chamber? The setup is simple vacuum system; all you need is a vacuum pump with a vacuum chamber. We have made several of these systems before. As you can see, the elbow pointing upwards is a NW 50 vacuum connection which connects to a high CFM vacuum pump. We have done several of these types of chambers of the years.

We have a write up on: Quality Control of Seals and Seams of Canned Food or Food Containers you can read that article by clicking on the link above.

In this incident, our client had determined that seam strength of their food cans was inversely proportional to seam failures. Meaning that the stronger the seam of the food can was, the less failures occurred. In hindsight, this is a logical conclusion, however, sometimes this relationship between seam strength and seam failure must first be quantified.

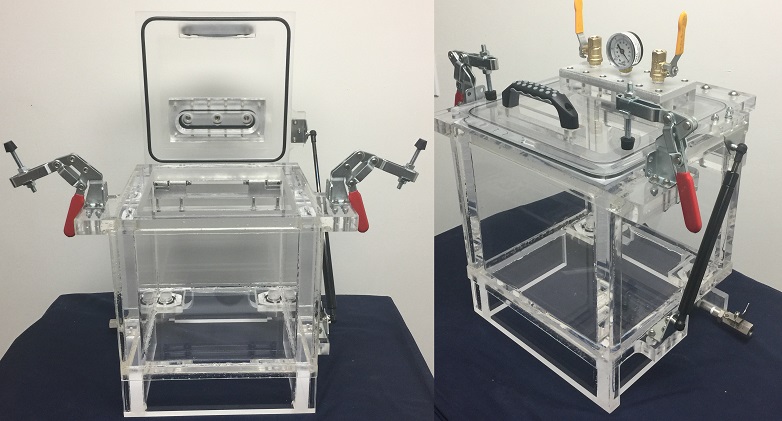

Armed with this knowledge, our client had opened the door for a more versatile and cost-effective leak testing options. They were not looking for a high-priced helium leak testing system, nor were they looking for another low throughput high priced leak tester. Since they knew that seam strength was inversely related to seam failures, they were able to come to us and have us design a seam strength testing system by utilizing an acrylic vacuum chamber.

Their requirements were to introduce as much structural stress as possible as fast as possible onto their food can in order to induce buckling of seam. What we suggested was to get a high volumetric flow vacuum pump along with our smallest acrylic vacuum chamber and connect these two with a NW50 valve. It would take 9 seconds to evacuate the vacuum chamber from atmosphere to 1 Torr from the moment the valve opened.

As a part of their testing procedure, they would film the behavior of their food can. Their testing process would repeat every 5 minutes. If the can failed, the production canning line would stop. The engineers would review the video and determine the failure mode. There is some really cool video footage of fish parts flying and bouncing around the inside of a vacuum chamber which can happen if you have a weak seam and you have applied about 500 pounds to the tuna can within 9 seconds. Stuff goes from “zero to a hunnit real quick”

We never asked them what their cleaning procedure was after the fish explosion incident...

But we will ask you to Contact Us if you are testing seams on your food can production. I think you should at least give us the opportunity to take a look at your project.

Did you know that we carry a many more products?

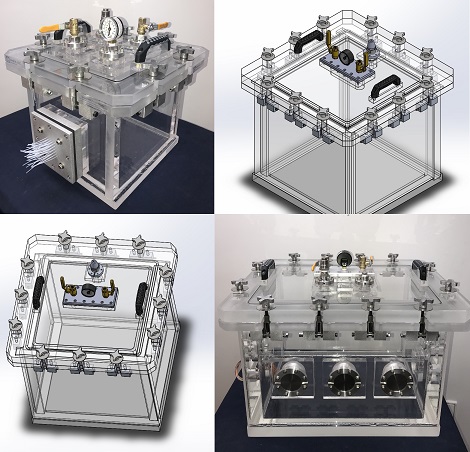

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers