Quality Control during Production runs is a very important procedure you must perform on your manufactured products. This is especially critical is you are an FDA manufacturer where regulatory compliance is important and necessary. Our Vacuum Chambers are specifically built to assist you meet your Quality Control and Regulatory compliance needs.

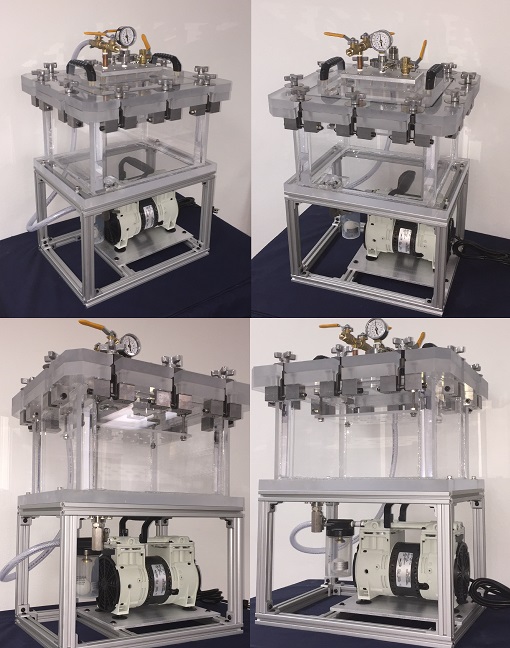

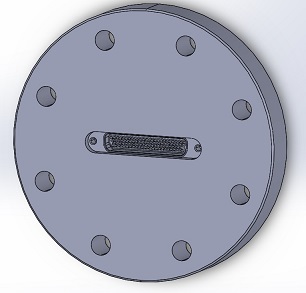

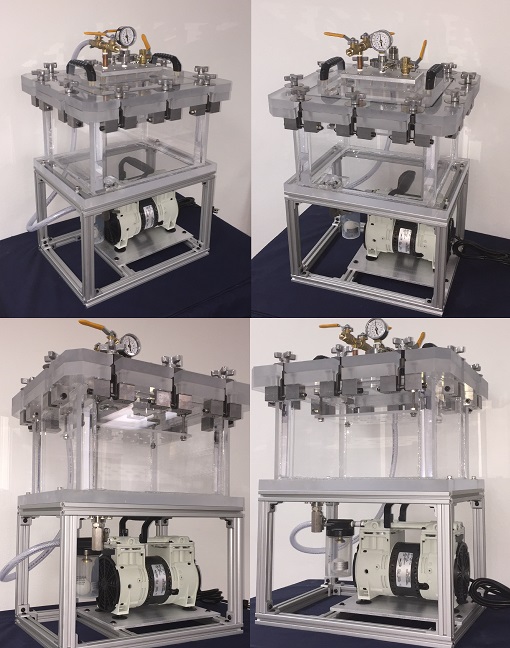

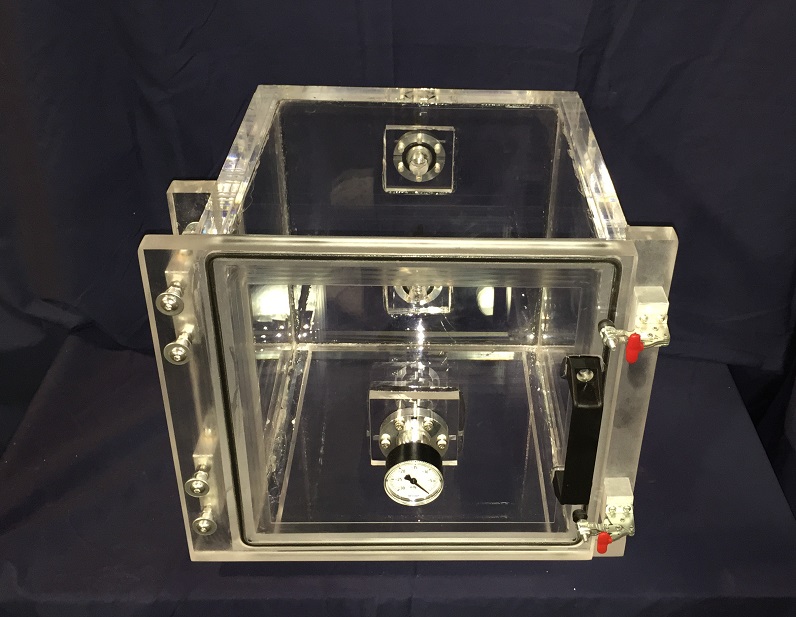

This is a custom Bubble Leak Testing System that has been converted to a vacuum and pressure chamber. There are several cool tests that can be performed with this system. The first test is a dry vacuum test which can be used to vacuum leak test products such as heat-sealed pouches or trays. The second test is a bubble leak test. This is performed by filling the acrylic vacuum tank with water and submersing the pouches underwater and looking for bubbles. The lid has a package restraining mesh which keeps inflated specimen from buoying upwards during the bubble emission test. The third test is a pressure test meaning that this chamber can be safely pressurized up to pressure between 5 to 15 PSIG. You do not have to think about adjusting your pressure in order to keep below the specified overpressure because this system has a safe pressure relief valve that will pop open if the pressure has reached more than 10 PSI Gauge Pressure. Of course, there is also a water drain valve located on the bottom wall of the chamber.

This system comes with an Oil Free Piston Vacuum Pump which does not emit oil mist into its surrounding. The vacuum pump does not require much maintenance either. You can see that the pump has a Vacuum Pump Protection Valve which will prevent any water from entering the vacuum pump. The Lid is fully removable and versatile. This is a table top system intended to be operated inside a clean laboratory or an FDA manufacturing facility as part of Quality Control.

Are you required to be regulatory compliant? You are an FDA approved manufacturer? Contact Us to learn how our products can help you with your FDA compliance.

Did you know that we carry a many more products?

We make Robustly Designed and Quality Engineered Systems. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers