There are countless chemicals and metals that interact with Steel or Stainless Steel. According to our investigation, Gallium, Cadmium, Beryllium, and Zinc are some examples of materials which will interact with Steel or Stainless Steel during vacuum Storage.

A leading manufacturer or X-Ray components contacted us because another happy client connected us. Their requirements were simple, they wanted to vacuum store some of their X-Ray assembly components inside vacuum chamber. Metallic Vacuum Chambers were out of question because there was a damaging chemical interaction between the X-Ray Components and the metallic walls of the vacuum chamber. At first, we had to investigate to confirm that acrylic was a good candidate.

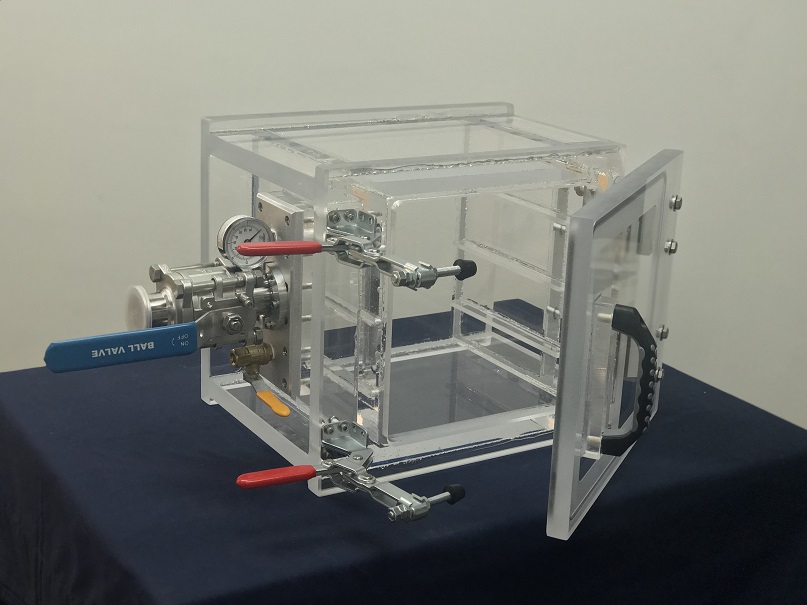

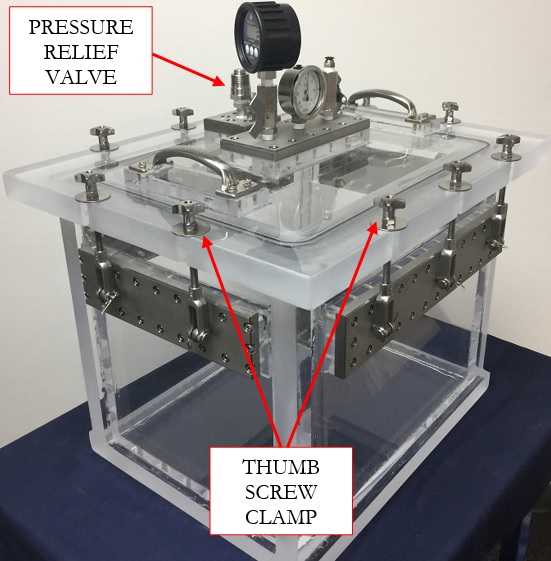

What you are looking at is a small Acrylic Vacuum Chamber, with shelve holders that will allow our client to place their X-Ray components onto shelves and store them in a vacuum environment. Additionally, they requested an NW40 Vacuum valve since their current vacuum connection was a NW40 vacuum hose that they could easily hook up.

If you are working on developing cutting edge X-Ray equipment and are in need of a vacuum chamber system, Contact Us to find out why so many clients are happy with our products.

We have many more resources on our website that you should check out

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers