Food cans which are hermetically sealed or seamed are the most consumed type of food in the United States. Fully 60% of all food consumed in a given day in the US is either canned food or food from containers. Food can seal failure can expose the consumer to an unnecessary amount of risk. Given that risk and the number of consumers present at any given day, it is very important to produce high quality seals and to test for seal integrity.

Helium Sniffer Test

There are several ways to test food cans for leaks, one of them is to perform a helium leak test by puncturing the can and injecting it with helium. If a leak is present helium will escape out of the can and will be detectable with a helium sniffer.

Helium Leak Test

A helium leak test is performed by flooding the food can with helium and by inducing a pressure differential, in most cases it is done inside a vacuum chamber, in order to force the helium through the orifice or leak path. A helium leak detector will detect presence of helium and therefore fail the part. This is a nice test as it can help quantify the size of the leak. More helium present inside the leak detector, means a greater leak.

Pressure Decay Test

This is done by applying pressure to the food can through a pressure probe. Once a set amount of pressure is reached, the pressure valve is closed and the pressure transducer begins recording the pressure drop over a time period. If a leak is present, the change in pressure will be greater than a non-leaking part. In that case, the can is rejected. Just with a Helium Leak Test, the leak size can be quantified based on the rate of change of pressure.

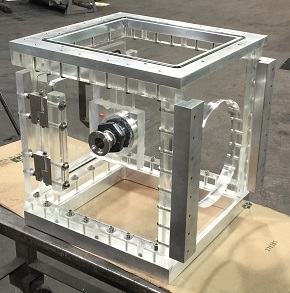

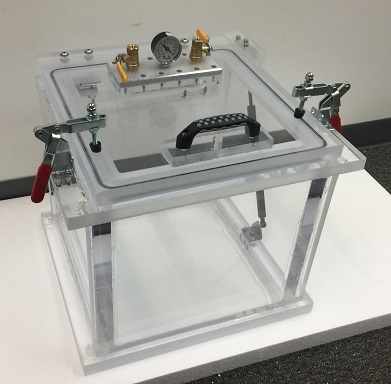

Vacuum Chamber

You can also use a vacuum chamber to quality test your food cans. The strength of a seam is inversely proportional to seam failures. You can therefore test for seam strength by subjecting the can to vacuum. If the seam is damaged, you can a weak seal and a leak failure. Conversely, a puncture will also be detectable by the fact that placing the food can into a vacuum chamber will create a pressure difference. The high pressure contents will press through the puncture and at that point can be visually inspected for.

So, there you have it, you can perform a helium sniffer test, a helium leak test, a pressure decay test, or a vacuum leak test to inspect for leaking food cans.

Some of our Popular Items

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). Check out some of our other items we carry that you can combine/integrate with your systems or projects.