The aforementioned ASTM 4169-16 test consists of: Shock / Drop, Compression, Vibration, Low Pressure Exposure, Impact. The acrylic vacuum chamber will be able to meet the Low-Pressure Exposure part of this test.

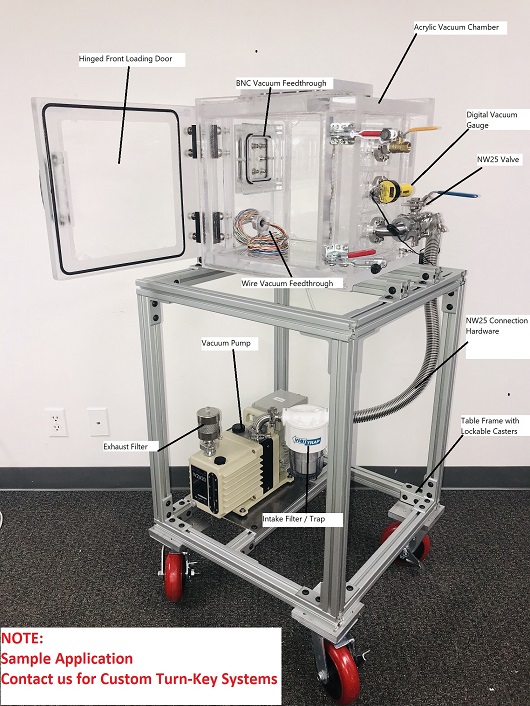

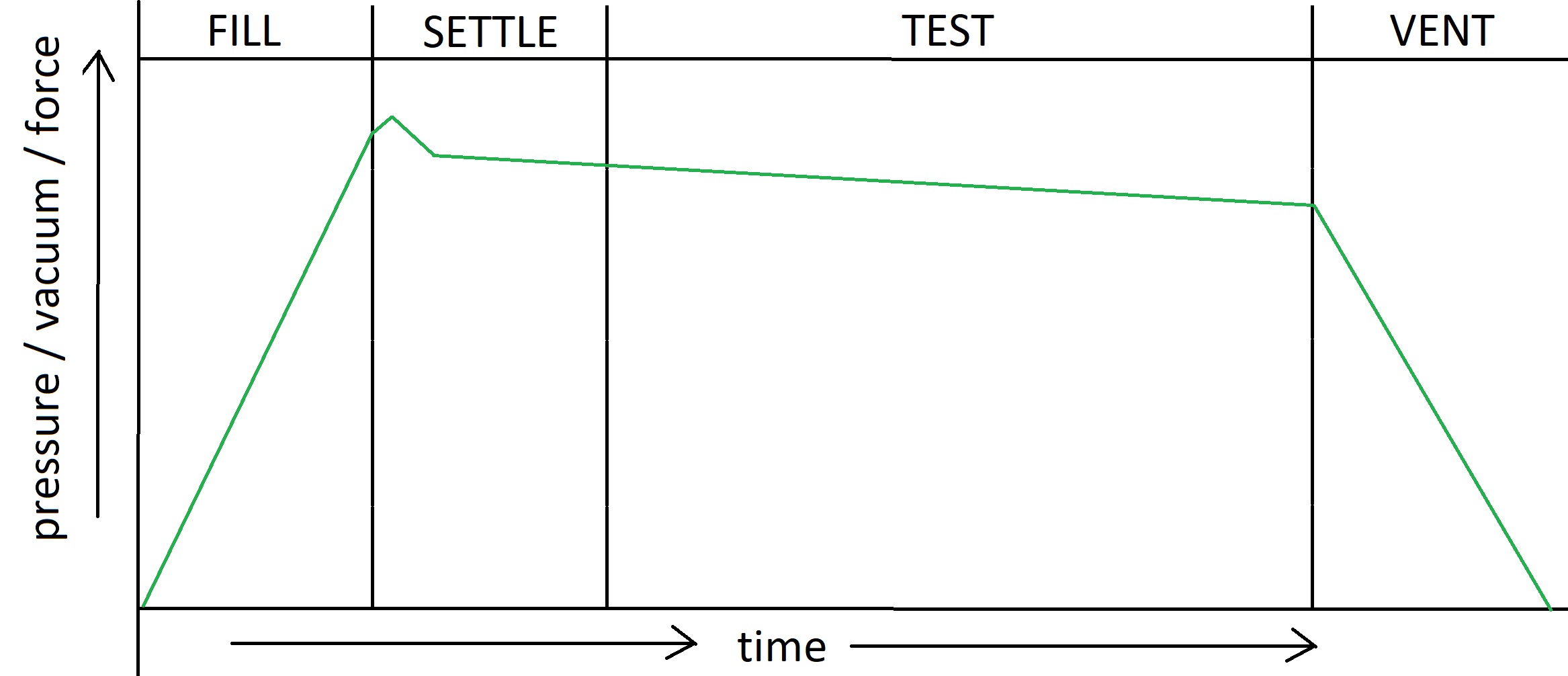

Keep in mind that we are talking about the Acrylic Vacuum Chamber only. The ASTM 6653 requires a pressure decrease of 1000 ft every 30 seconds to 60 seconds until the altitude equivalent of 16,000 ft or 400 Torr has been reached. You would need a vacuum controller in order to be able to achieve such vacuum increase/decrease and hold - which we do offer.

Many of our clients use our acrylic vacuum chambers to perform package quality testing. Many are package testing laboratories while others are package testing labs that the companies decided to bring in house in order to consolidate resources without having to contract out their package testing needs.

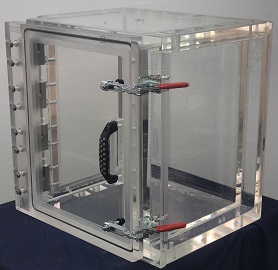

The most popular vacuum chamber used for the ASTM D4169, including the ASTM 6653 test is our acrylic vacuum chamber, hinged side door, front loading. As long as our customer tells us that they are looking to mount this chamber to a vibration table, we gladly add mounting holes onto the bottom wall of the chamber so that it can be mounted to a table.

Reach Out to us if you have any questions with regards to the ASTM D4169 Test.

Similar Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers