Microfluidic Testing using an acrylic vacuum chamber

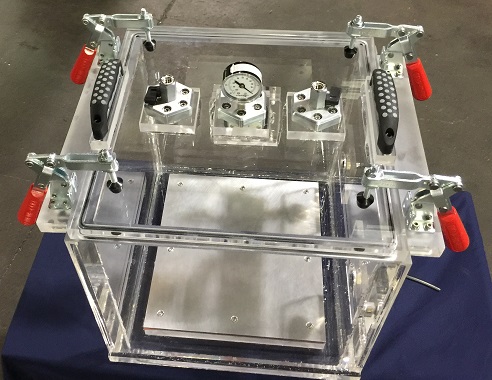

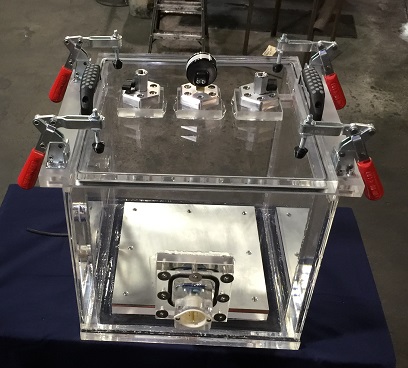

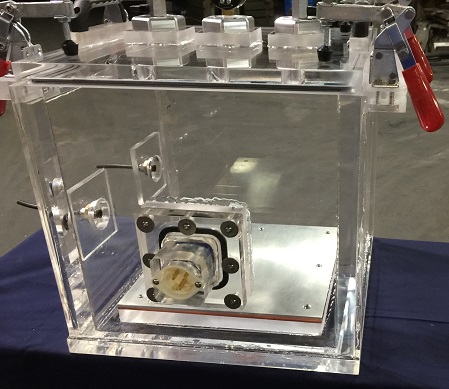

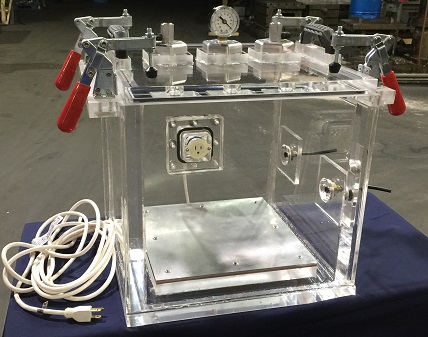

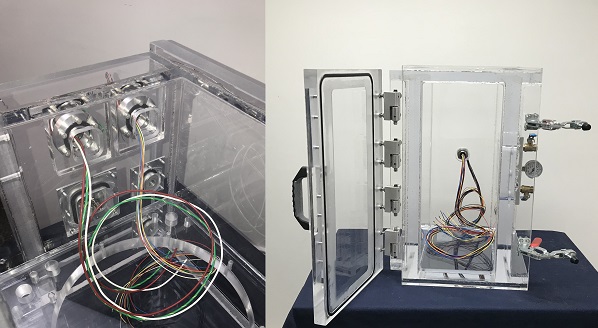

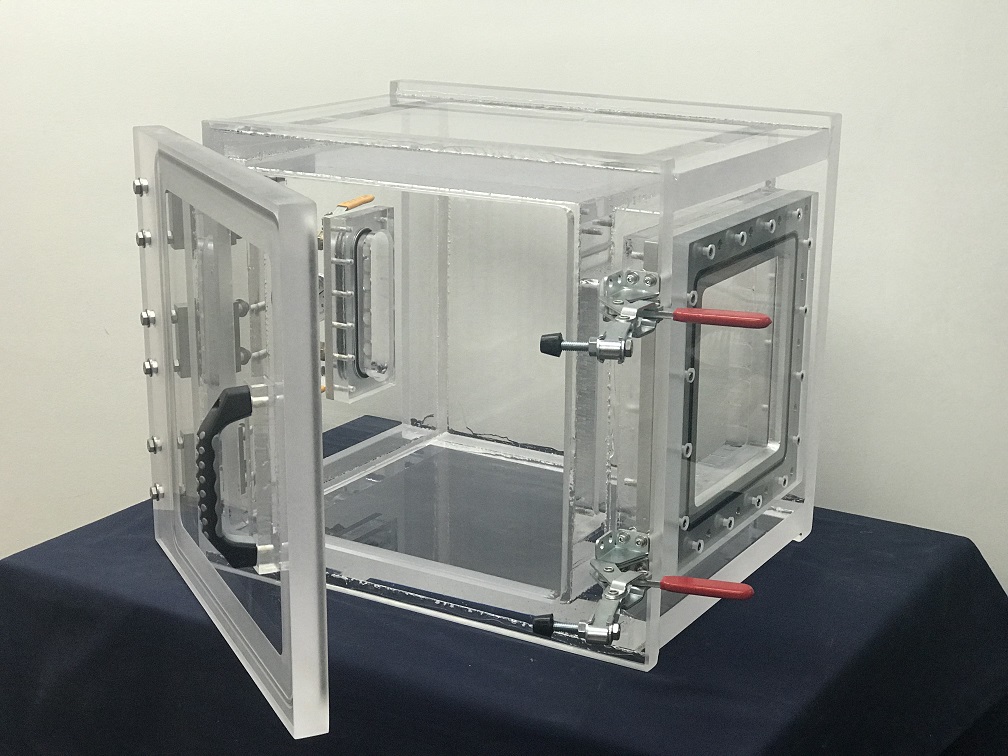

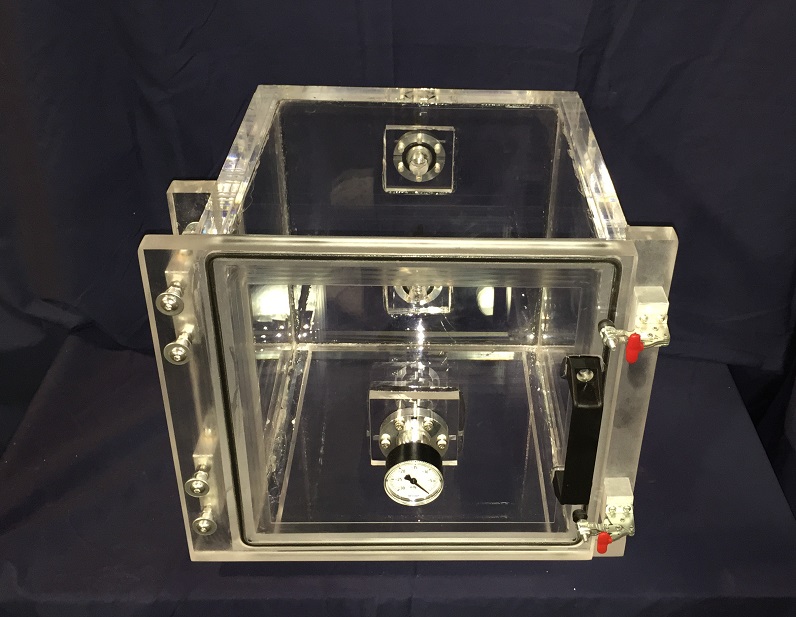

Our client performs a wide array of microfluidic testing in their laboratory. The requirements were 1. to install injection ports which are connected to a syringe pump outside of the chamber, 2. A gas port to pump gas such as carbon dioxide, helium, or argon into the specimen, 3. an electric feedthrough port in order to connect a heat plate and heat the sample inside the chamber during vacuum tests.

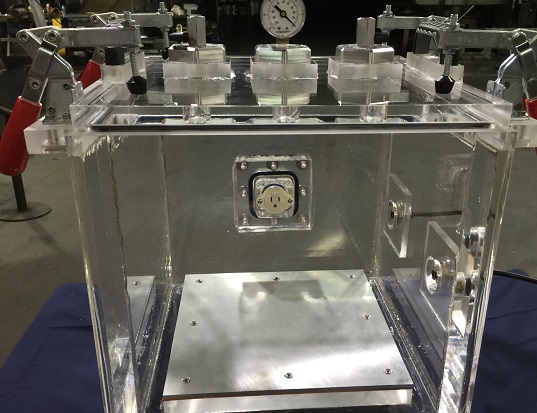

This was a custom chamber to which we added two feedthrough ports and an NEMA 5-15R power outlet (The same used in many US homes to power basic household appliances such as TV or a microwave)

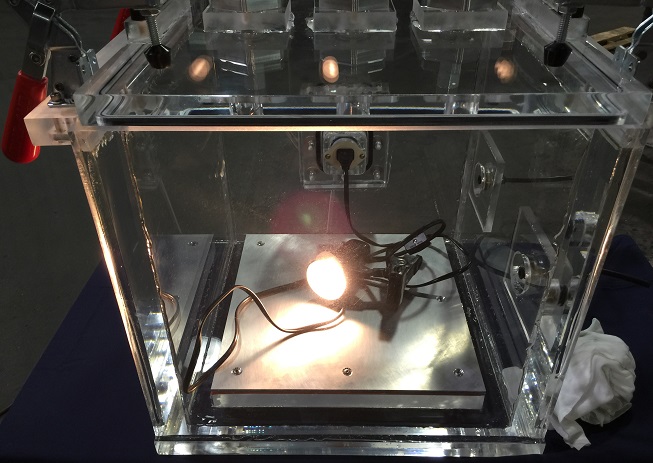

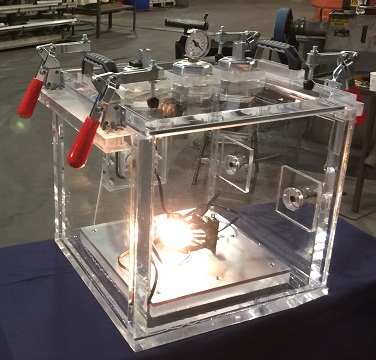

The final design also included an aluminum base plate along with a heat insulator beneath to protect the bottom chamber wall from heat damage. Take a look at the light bulb being turned on as we pull a full vacuum on this chamber.

We have many more resources on our website that you should check out

We are an Engineering Excellence Company. Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers