Vacuum sample preparation and laboratory testing

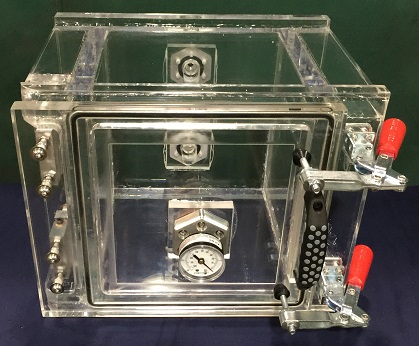

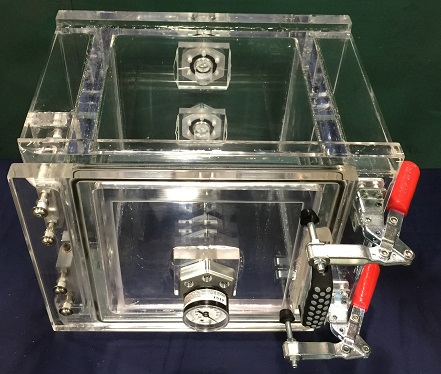

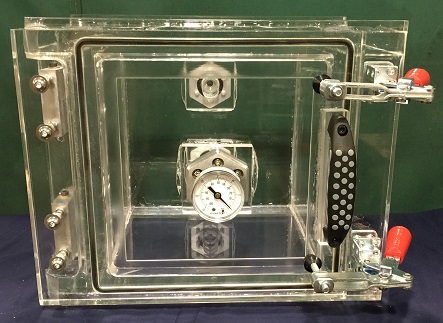

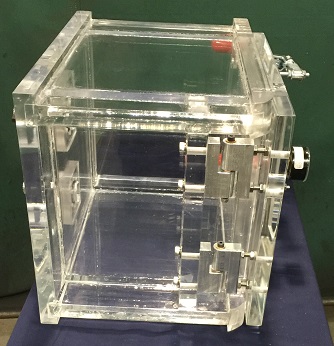

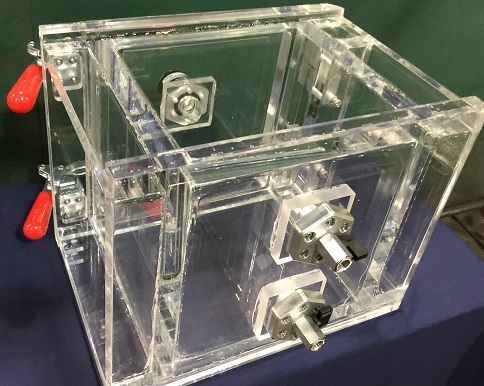

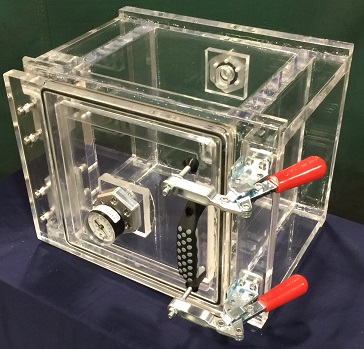

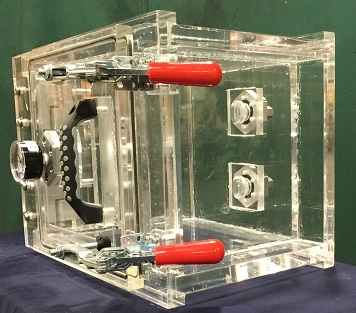

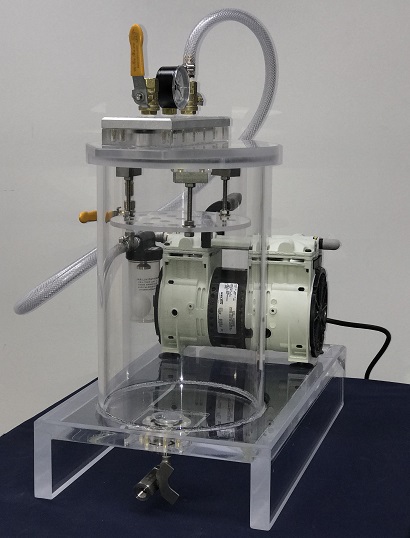

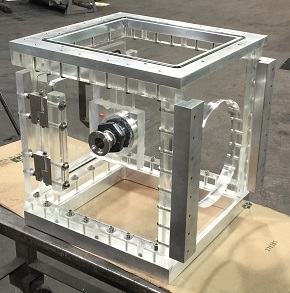

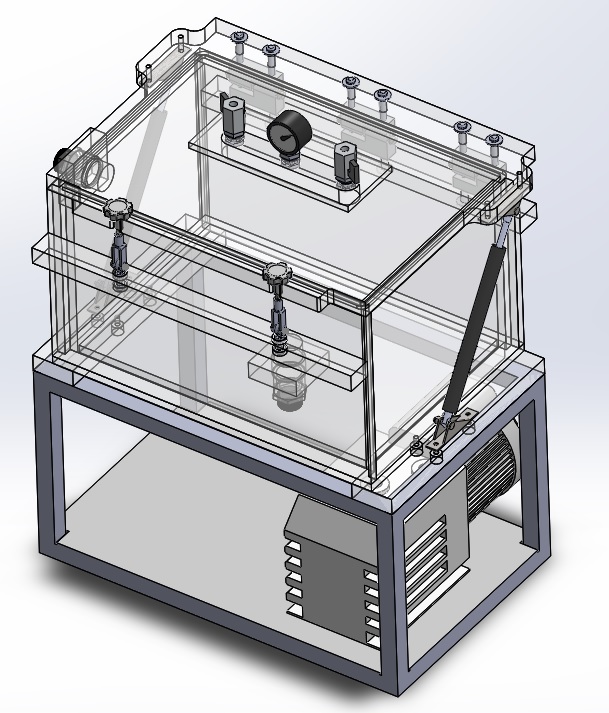

This is our standard 10 inch cube inside dimensions chamber made for vacuum sample preparation and laboratory testing. Our client needed a vacuum chamber that is high performing and robust which is why they came to us. This chamber has a vacuum rating of 250 microns absolute pressure. Included as a standard are: a vacuum valve, a vent valve, a vacuum gauge, two toggle clamps, two hinges, one handle.

The client�s samples are prepared through vacuum evaporation and vacuum degassing. A wide range of samples is used in this vacuum chamber. A hinged side door comes especially handy in laboratory environments because it can be placed onto the bench top. The door can then conveniently be opened where samples are placed allowing a high throughput rate.

Our chambers are the only chambers designed robustly and quality built to perform even in the most demanding laboratory environments!

Similar Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers