Coffee is one of the most popular refreshment drinks of the world. There seems to be no end to its popularity growth. If you are a coffee processor, manufacturer, or packager, it is imperative for you to test the seal integrity of your coffee bags. The main reason is that improperly sealed coffee bags are at risk of mold development. Another reason is that a fault seal can cause the coffee to become stale.

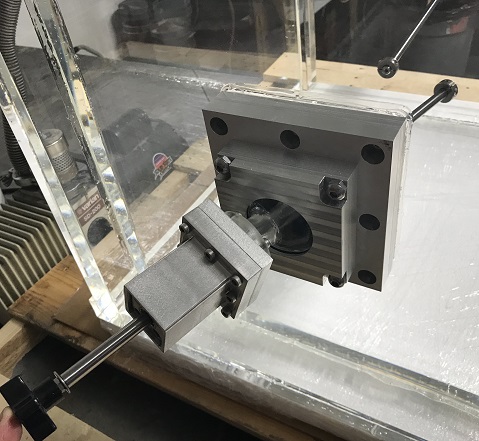

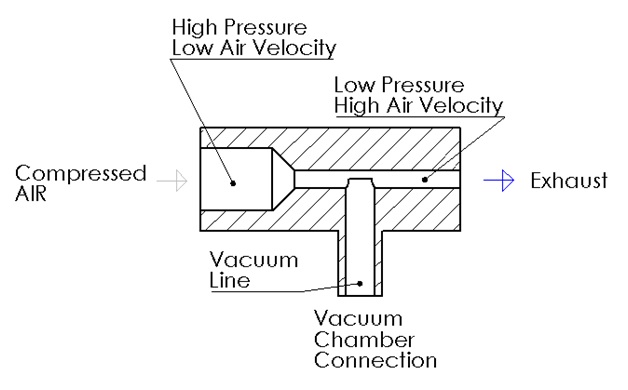

Fortunately, there is a simple way to test for heat seal quality of your coffee bags by using a Bubble Leak Tester. This is a simple seal integrity testing unit that will allow you to perform a dry test and a wet test. The dry test is performed by pulling a vacuum and watching the coffee bags inflate. If the bag explodes, you may have a weak seal. The wet test is performed by dunking the coffee bags underwater, pulling a vacuum, and looking for bubbles emitting from the test specimen. If you observe bubbles, you have a leak.

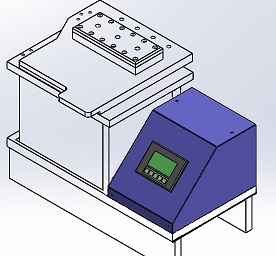

This chamber size of the system is 12 inches diameter and 15 inch high. The vacuum pump is an Oil Free Gast Vacuum Pump capable of pulling about 22 inHg of Vacuum – this is enough in most cases to perform a dry or wet package leak test. Below the chamber is a drain valve which will enable you to drain the water from your tank without having to tip it. Next to the chamber is a Vacuum Pump that does not require much maintenance since it is oil free. This is a complete system, it is fully setup and ready to go all you need is to plug the vacuum pump in and just add water to start bubble leak testing.

Are you packaging Coffee Bags, Tea Bags, or other types of consumable products? If you are, Get in Touch with us to find out how you can produce the highest quality heat seals.

You may be interested in some of our other items

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers