Did you know that you can quality test your pet food by using our bubble leak testing system? I am not sure if pet food is subject to FDA regulation. As far as a quick google search goes, FDA ensures that pet food is safe and that it serves the intended function. In order to for the manufacturer to produce safe pet food, it must be tested for seal quality and container closure. We don’t want our newly adopted best friend to be eating spoiled food. The question is: would your newly adopted dog tell you that the food she’s eating tastes spoiled? And two, let’s be real here, who do you think adopted who in the first place :)?

Just as our Bubble Emission Testing System can be used to test for seal integrity on food made for human consumption, medical packaging, and nitrogen filled pouches, it can also be used to test for seal and closure integrity of pet food.

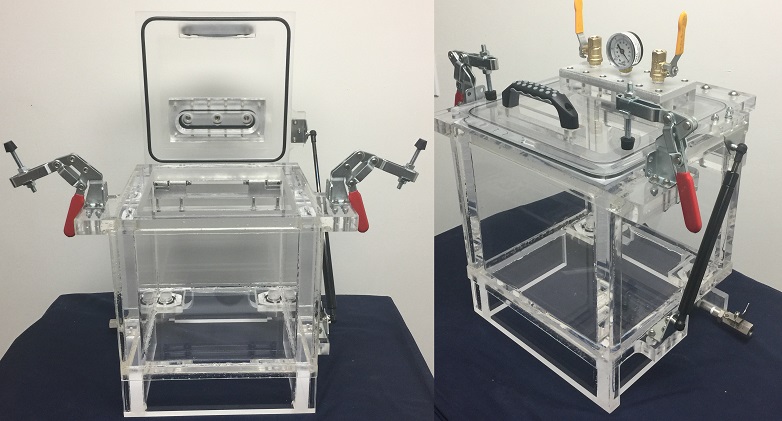

What you are looking at is our standard 12 inch Wide, 10 inch Deep, and 8 inch high bubble leak testing system with a rotary vane pump placed on an aluminum frame structure. This system is fully setup and ready to go, just add water.

Are you quality testing your pet food products? If you are, contact us to see how we can be of service.

We have many more resources on our website that you should check out

We are an Engineering Excellence Company. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers