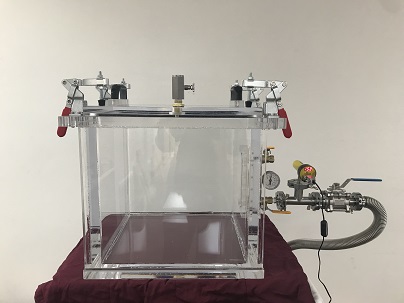

Custom Leak Test Chamber for Power and Energy Applications

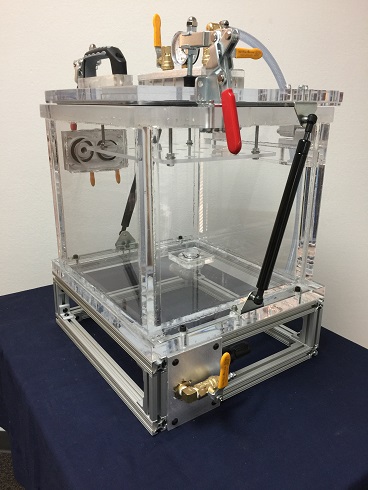

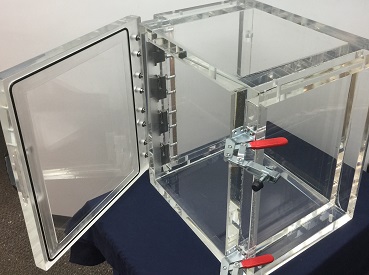

Additional Images of Sanatron Custom Engineered Systems

A showcase of images presents our masterfully engineered Standard and Custom Engineered Systems, each designed with an uncompromising focus on resilience, accuracy, and peak functionality. Whether your project necessitates a pre-configured vacuum chamber or a fully customized, end-to-end solution, our expertise guarantees seamless integration with your precise specifications. Contact us today to tap into our wealth of knowledge and develop a solution meticulously crafted to meet your exact demands.

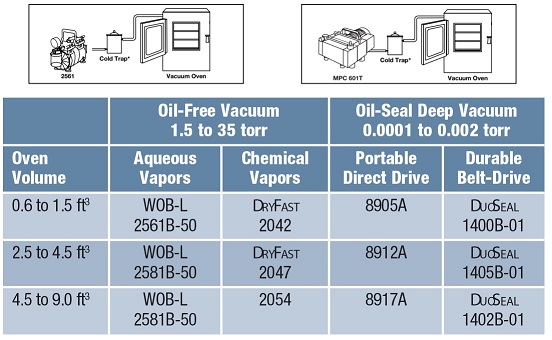

Product Specifications

Features

Description

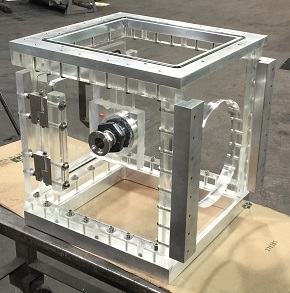

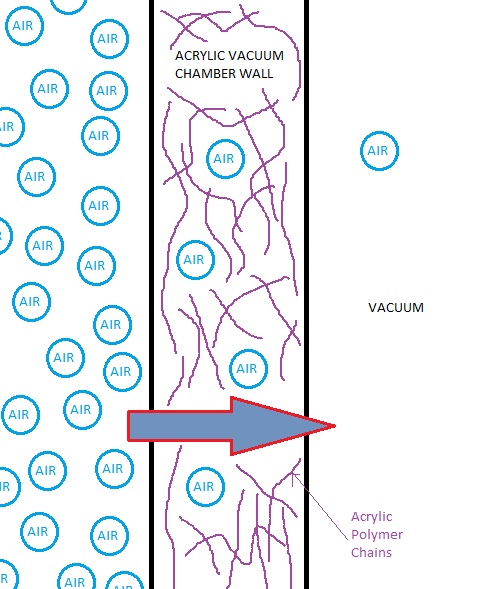

Introducing the Sanatron high-performance leak test chamber, expertly constructed to address the requirements of the power and energy industry. This custom-engineered solution is designed to deliver reliable and precise testing, ensuring the structural integrity of essential components. Built with crystal clear acrylic, this chamber offers exceptional durability and functionality for demanding industrial applications. The horizontal cylindrical design, complete with a front-loading mechanism and hinged door, streamlines the testing process while maintaining superior efficiency. Its dependable Viton O-ring Groove creates an airtight vacuum seal, making it an excellent choice for leak detection in even the most challenging conditions.

This table top leak test chamber features a 10 inch inside diameter and a 10 inch depth. A dial vacuum gauge placed on top. It comes with four NW25 ports two ports are featuring a 1-pin 500V, 5 Amp Power Feedthrough. The other two NW25 ports featuring a 0.5 inch NPT with plugs to accommodate diverse testing.

Compact yet powerful while ensuring compatibility with various testing setups. Specifically tailored for leak detection applications, this chamber exemplifies precision engineering for businesses seeking dependable solutions. Whether you’re testing small parts or larger assemblies, this vacuum leak testing chamber delivers industry-leading performance for power and energy suppliers worldwide. Contact us if you are looking for a leak test chamber.

We have many more resources on our website that you should check out

We make Robustly Designed and Quality Engineered Systems. What are you building? Take a look at the links below and discover some of the cool things we make.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.