Automotive Manufacturing and Emissions Testing Vacuum Chamber Solutions

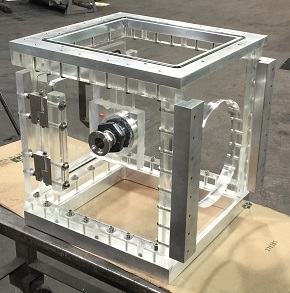

Additional Images of Sanatron Custom Engineered Systems

Explore additional images of our Standard and Custom Engineered Systems, each meticulously designed and built to meet unique specifications. Whether you need a standard vacuum chamber or a fully customized turnkey solution, we tailor our products to fit your exact requirements. Contact us today to discuss your project and discover how our expertise can deliver the perfect solution for you.

Product Specifications

Features

Description

Sanatron vacuum chambers are designed specifically for the automotive industry in order to deliver exceptional reliability and precision for critical processes. Whether for emissions testing, material testing, component manufacturing, or research and development, our chambers provide the accuracy and durability needed for modern automotive applications.

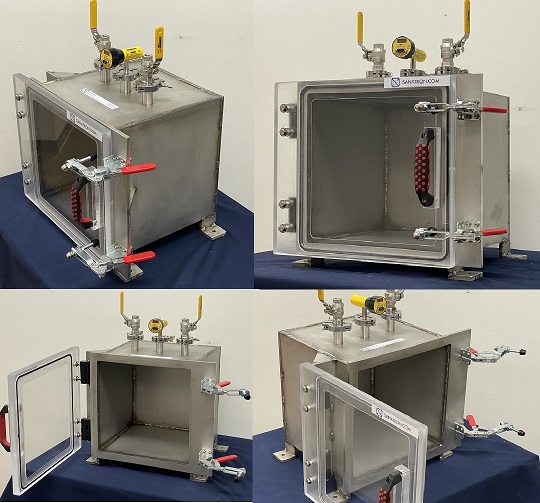

This project is a special design featuring a pressure and vacuum chamber with 12-inch cube inside dimensions. The pressure rating is 5 psig positive and fully vacuum of at least 0.075 Torr absolute. There are two USB Vacuum Feedthroughs on the front wall that allow for running signals into the chamber during emissions tests. There is also another spare port on the Right Wall installed for future expansions. The lid comes as a standard with a pressure relief valve, two valves and a dial vacuum gauge. This vacuum chamber is optimized for use as automotive testing chamber, enabling you to evaluate components under simulated real-world conditions such as pressure and vacuum and ensure compliance with industry standards.

Sanatron automotive manufacturing vacuum chambers streamline production workflows while maintaining peak performance. From prototyping to mass production, our systems help automotive manufacturers achieve consistent, high-quality results. With a focus on innovation and efficiency, we provide cutting-edge vacuum chamber solutions tailored to the unique needs of the automotive sector. Trusted by thousands of companies, our chambers set the standard for robust design, reliability, and quality manufacturing.

Some of our Popular Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. You should check out some of our other items we carry; click on the links below.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.