Semiconductor Vacuum Chamber with Advanced Vacuum Processing Capabilities

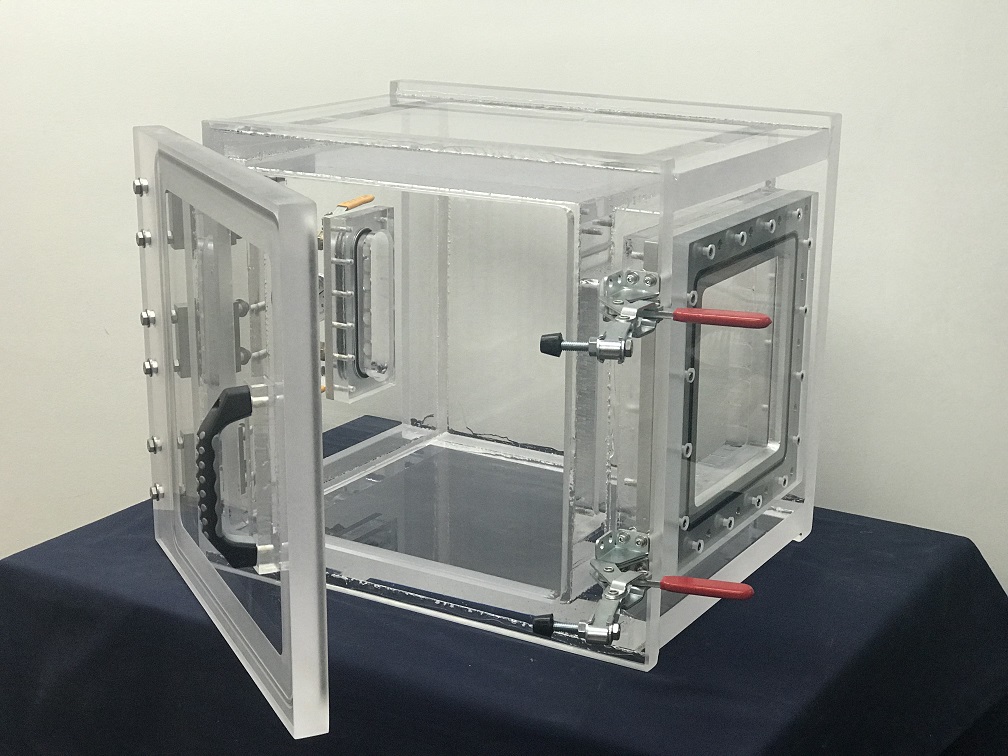

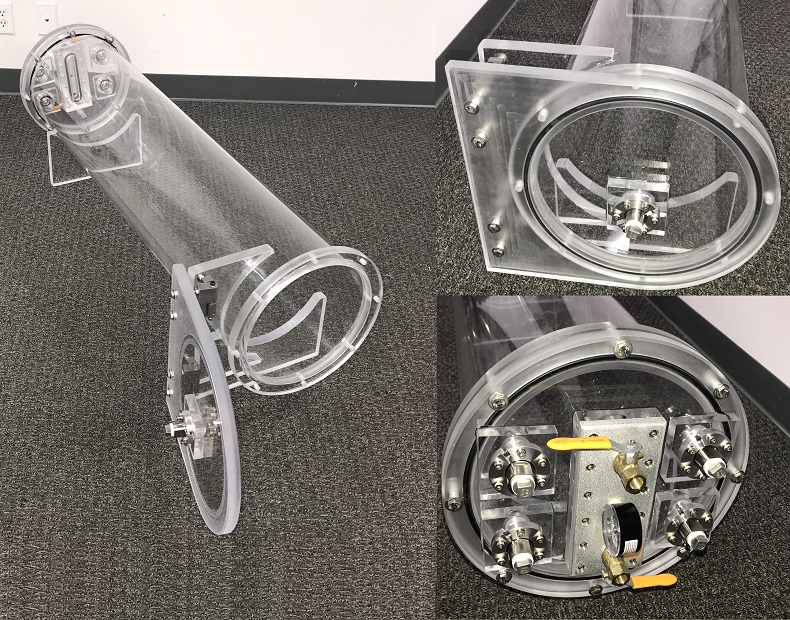

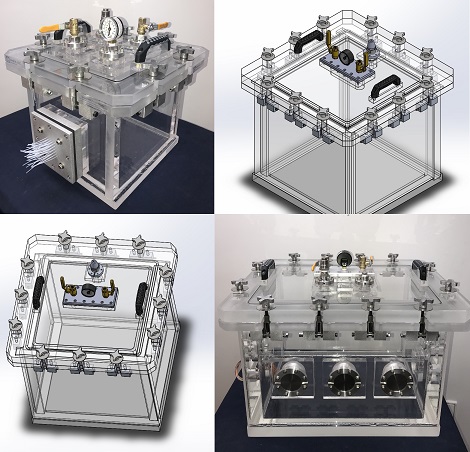

Additional Images of Sanatron Custom Engineered Systems

Check out a selection of images showcasing our precisely engineered Standard and Custom Engineered Systems, each built with an unrelenting focus on strength, accuracy, and peak efficiency. Whether your project demands a pre-configured vacuum chamber or a fully customized, start-to-finish solution, our expertise ensures seamless compatibility with your exact specifications. Contact us today to harness our deep industry insight and craft a solution designed with meticulous attention to your unique requirements.

Product Specifications

Features

Description

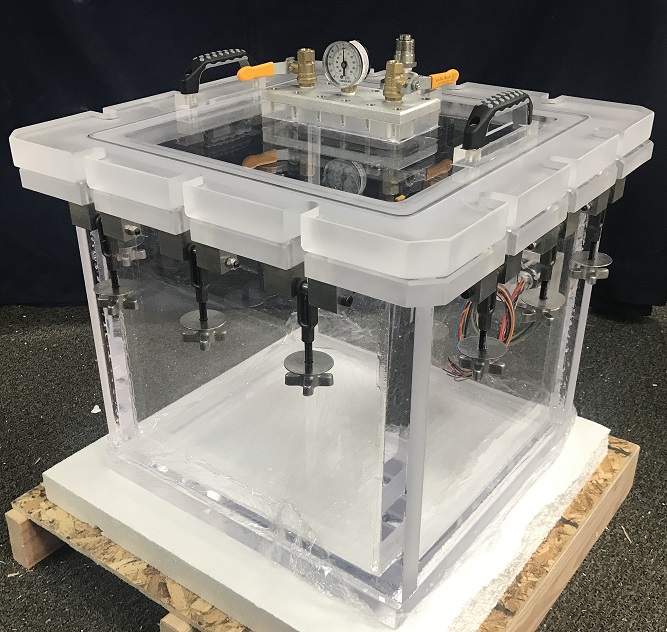

The semiconductor vacuum chamber is engineered to meet the demanding needs of the advanced semiconductor manufacturing process. A 16-inch cubic chamber made from clear acrylic, providing excellent visibility for monitoring chamber interior during vacuum operations. Designed with quality in mind, the front-loading configuration ensures ease of access, allowing efficient sample placement and removal. With its cutting-edge USB vacuum feedthrough, the chamber seamlessly integrates with modern data acquisition and control systems, enabling real-time process monitoring and control.

Incorporating three flexible and robust vacuum hinges, this semiconductor industry chamber guarantees smooth operation. The robust hinges enhance reliability while maintaining vacuum integrity, making it ideal for continuous use in a laboratory or industrial setting. The chamber features eight coaxial vacuum feedthroughs, allowing versatile connectivity for power, signals, or data transmission. This configuration is particularly beneficial for complex semiconductor experiments and production processes requiring multiple connections without compromising the vacuum environment.

This vacuum chamber stands out as a critical tool for the semiconductor industry, bridging precision and performance in a compact, reliable design. Its advanced vacuum processing capabilities make it suitable for applications such as thin-film deposition, plasma etching, or quality testing and control of semiconductor materials. The clear acrylic construction, combined with intuitive features like front loading door and seamless connectivity options, ensures that users can optimize workflow efficiency while achieving high-quality results.

WAIT! Take a look at similar Items you may like…

We are an Engineering Excellence Company. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.