Ethernet Vacuum Feedthrough, CAT5,CAT6, RJ45, Panel Hole, Dual Sided Connector

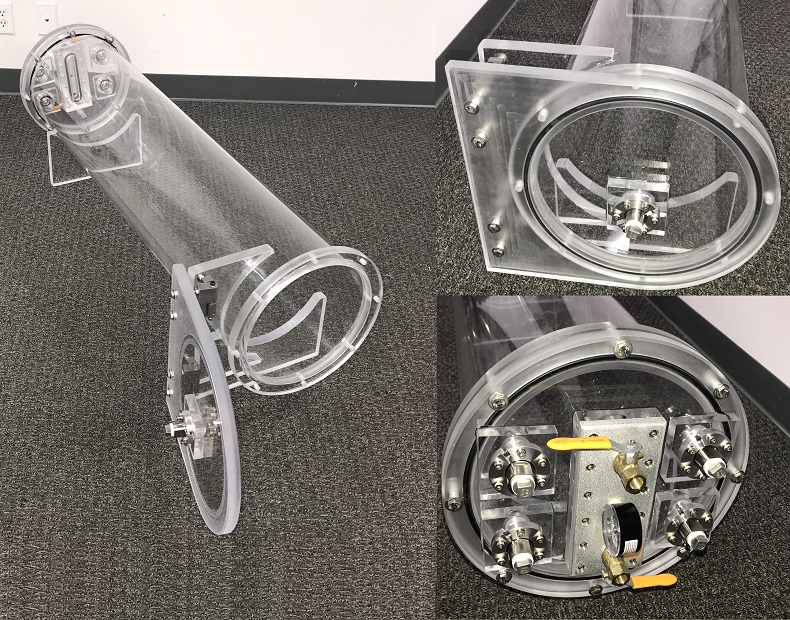

Additional Images of Ethernet Vacuum Feedthrough

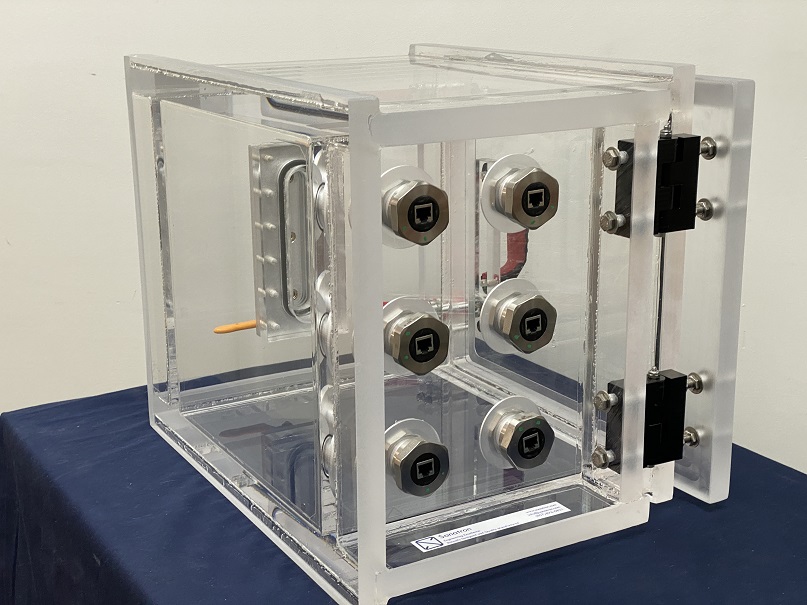

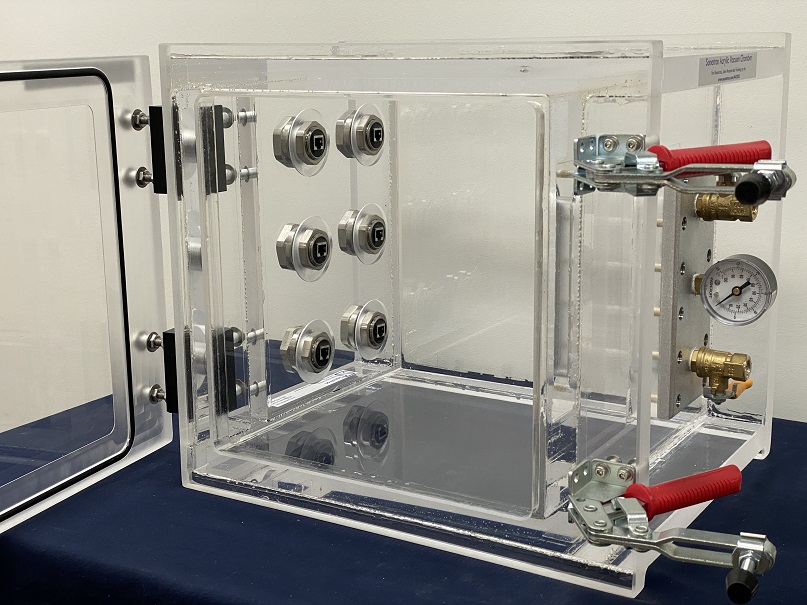

Our Ethernet Vacuum Feedthroughs can be customized and applied in any way imaginable. Please take a look at additional images of our Ethernet Vacuum Feedthroughs and it application examples.

Supporting Resources

Product Specifications

Features

Description

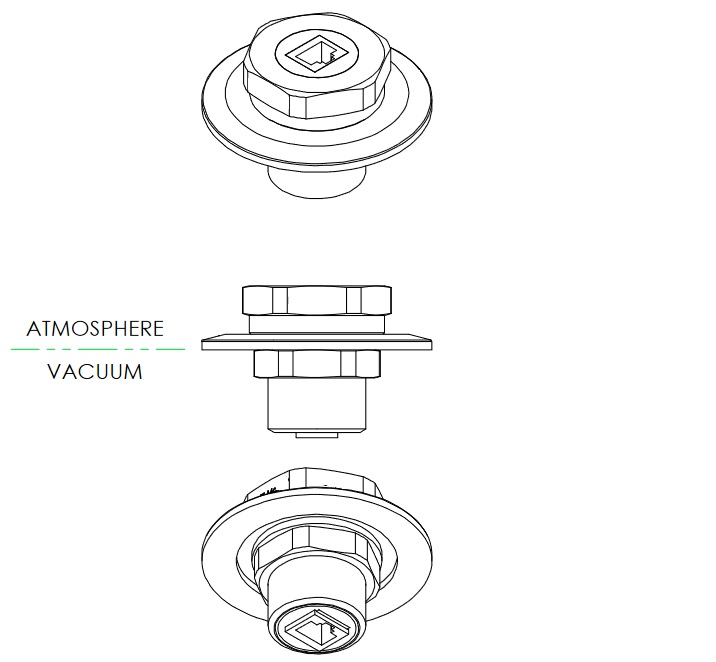

An Ethernet Vacuum Feedthrough is a component that will enable you to run ethernet cables into the vacuum chamber from the outside to the inside of the chamber during vacuum operations without compromising the vacuum.

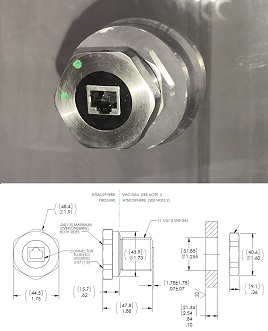

This particular ethernet vacuum feedthrough connects through a panel hole onto your vacuum chamber. The inside diameter of the panel hole is 1.25 inch while the panel depth must be between 0.10 inch and 0.84 inch. Once the feedthrough is placed into the hole, a locknut is used to tighten this component and to compress the O-Ring present on the inside of the flange to create an air tight seal.

This vacuum feedthrough is compatible with RJ45, CAT5, CAT6, and ethernet LAN connections. Feel free to contact us if you have any more questions.

Did you know that we carry a many more products?

Our clients prefer to work with us because we are Experts in Custom Fabrication (especially Polymer Fabrication). There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.