Vacuum Pump and Custom Chamber

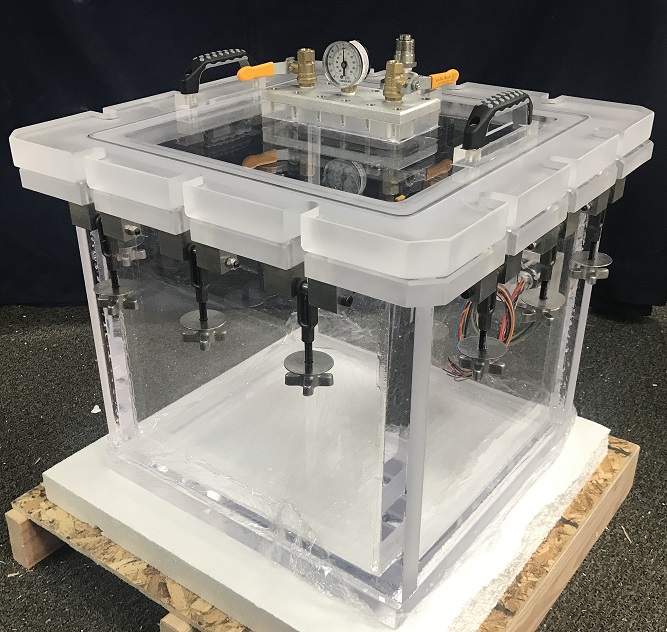

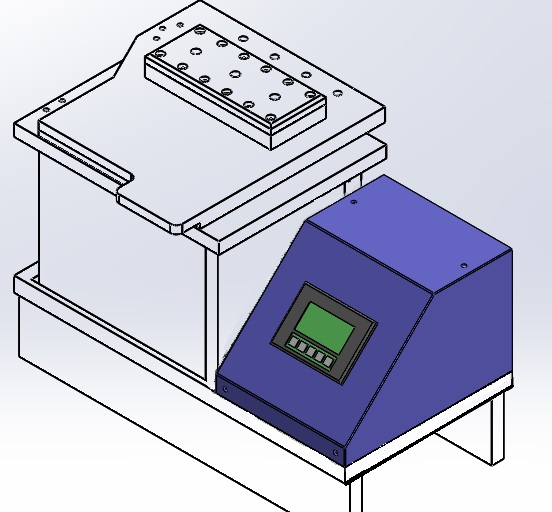

Additional Images of Sanatron Custom Engineered Systems

Explore an array of images presenting our masterfully engineered Standard and Custom Engineered Systems, each built with uncompromising attention to durability, precision, and peak performance. Whether your application calls for a pre-assembled vacuum chamber or a fully bespoke, concept-to-completion solution, our technical expertise ensures absolute synergy with your exact specifications. Reach out today and tap into our deep industry knowledge to develop a solution crafted with meticulous attention to your distinct needs.

Product Specifications

Features

Description

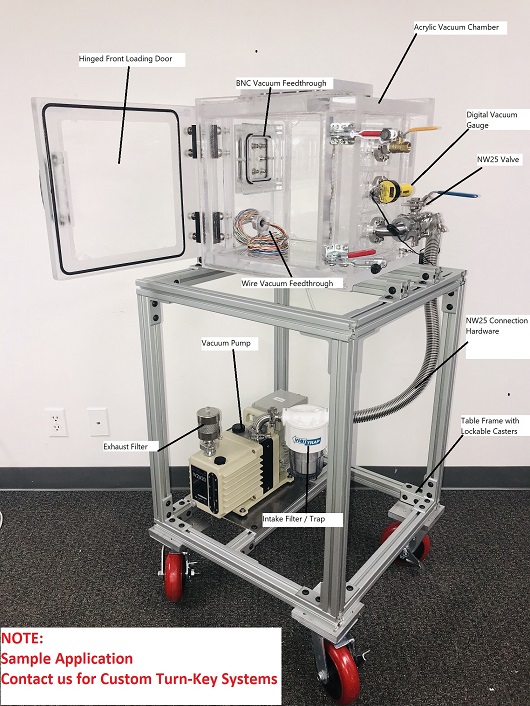

Sanatron Vacuum Pump and Custom Chamber is a purpose-built, table top, front-loading vacuum chamber with pump system. At 14-inch cubic interior, it provides a great platform for vacuum applications such as leak quality testing, material processing, and biotech or lab experiments. Quality engineered by Sanatron, with decades of experience in vacuum chamber manufacturing, this system delivers exceptional reliability and performance, reflecting the highest standards in precision craftsmanship. The Oil Free Piston Pump has been placed on top of the chamber in order to safe space.

Built to perform and last, this custom vacuum chamber boasts a robust design that withstands rigorous use while maintaining optimal performance. Its front-loading configuration ensures convenient access and efficient handling of sensitive components during operations. Designed as a custom-engineered solution, it caters to specialized fields such as biotech, medical device manufacturing, and advanced material testing. The seamless integration of a high-performance vacuum pump delivers consistent pressure control, empowering users to achieve precise and repeatable results across critical applications.

Sanatron unparalleled craftsmanship ensures durability, vacuum engineering, and exceptional performance in challenging environments. This vacuum chamber with pump is constructed with crystal clear acrylic and quality machined components, ensuring long-term dependability. We do offer smaller or lager vacuum chambers and pumps and if you are looking for a custom solution, feel free to contact us.

WAIT! Take a look at similar Items you may like…

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). What are you building? Take a look at the links below and discover some of the cool things we make.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.