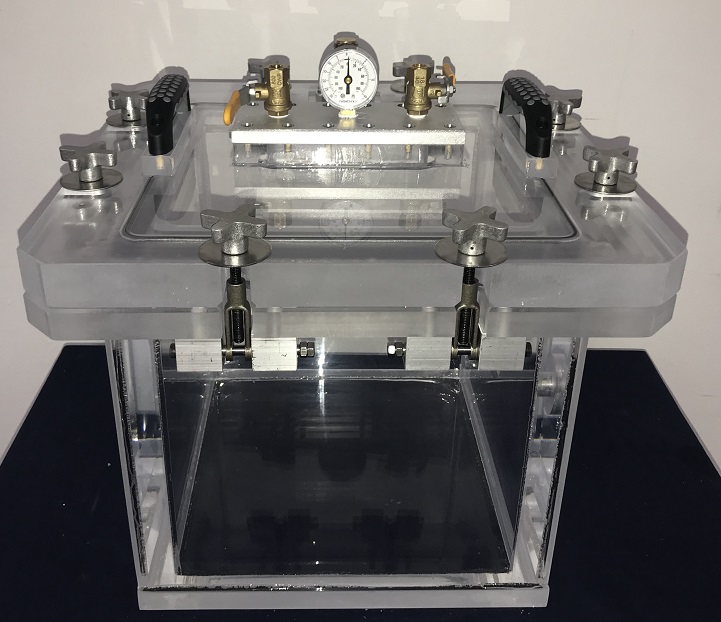

Pressure and Vacuum Chamber, Clear Acrylic, 10 inch Cube, Full Vacuum to 10 PSIG

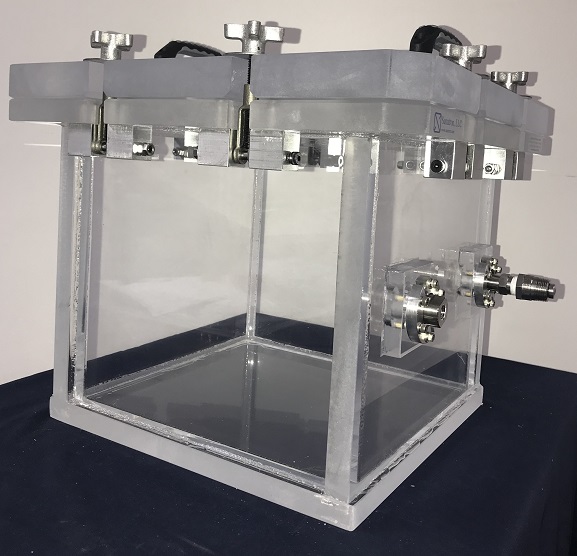

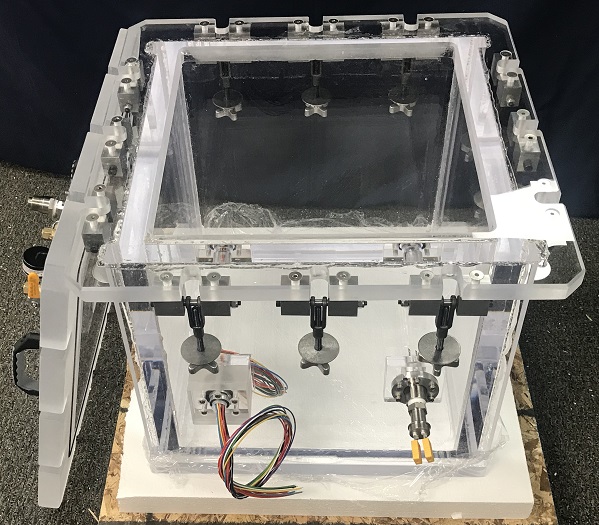

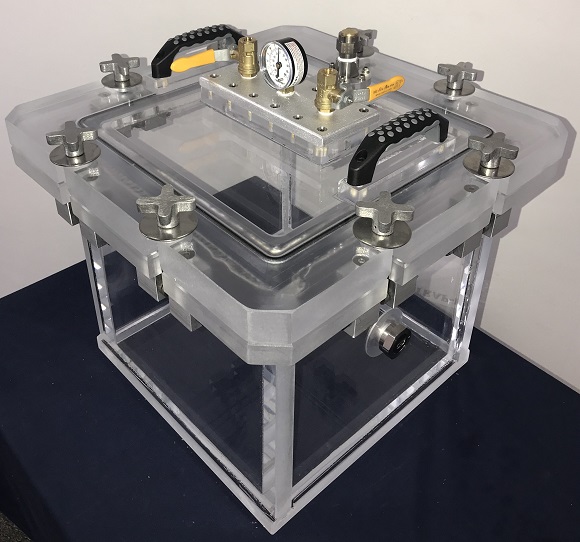

Additional Vacuum Chamber Images

Please take a look of some of the work we had the pleasure of doing for our clients. All our systems can be customized to your request. Feel free to contact us to see how we can help you design and build a good custom pressure and vacuum system.

Supporting Resources

Product Specifications

Features

Description

This is our pressure and vacuum chamber made from crystal clear acrylic capable of full vacuum (Torr Rating) and 10 psi gauge pressure. The inside dimensions of this chamber are 10 inch cube. This acrylic chamber comes with two (2) 1/4 inch NPT valves. One valve is used to supply vacuum or pressure to your chamber, the other is used for venting your chamber. You are also supplied with a dial vacuum and pressure gauge which will indicate either vacuum or pressure in dual scale in kilopascal (kPa) and PSI. Additionally, there are two handles that are placed on the fully removable lid. The lid is clamped down by thumb clamps during pressure operations.

This chamber also comes with a vacuum rated pressure relief valve that will pop open and release excess pressure if the pressure inside exceeds 10PSI so you never have to worry about inadvertently over pressurizing your chamber. There is also a 5PSIG and 15PSIG option available, please contact us to inquire more.

Fortunately, this chamber can be customized, many of our clients do so because they have specific project needs. Please reach out to us and we will be happy to have the opportunity to look at your requirements and customization needs.

Some of our Popular Items

Our clients prefer to work with us because we are Experts in Custom Fabrication (especially Polymer Fabrication). What are you building? Take a look at the links below and discover some of the cool things we make.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.