Pharmaceutical Manufacturing Vacuum System, Drying Solutions

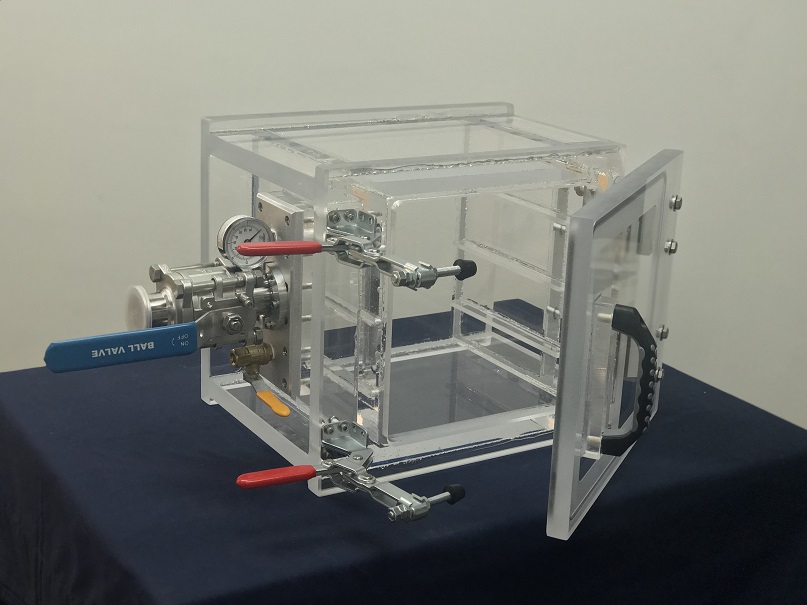

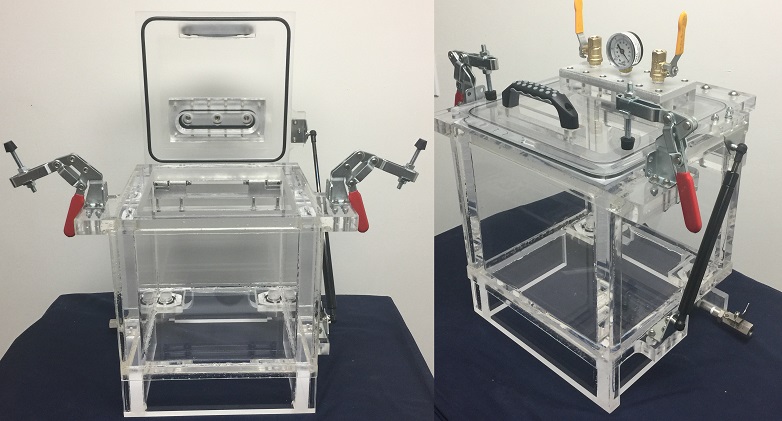

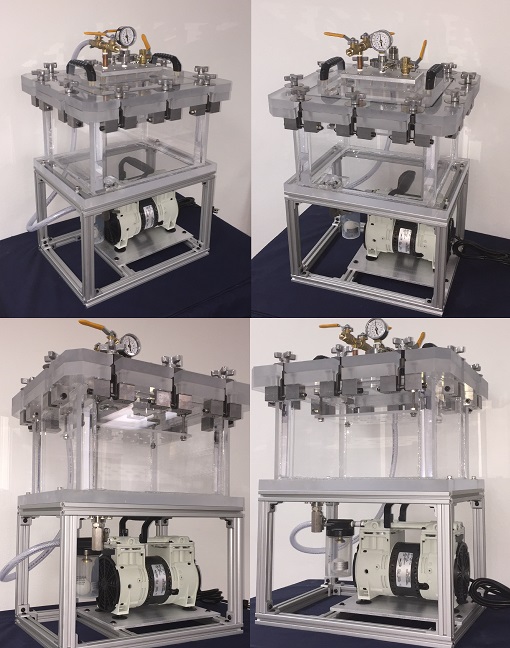

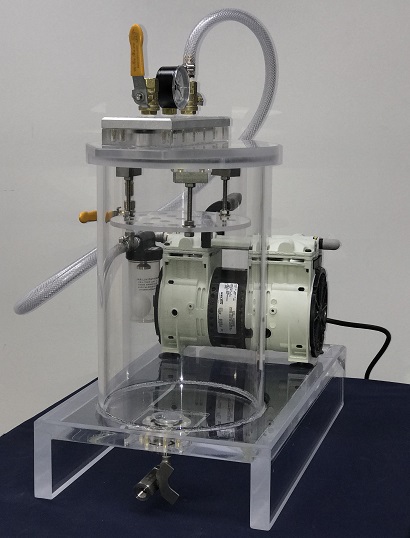

Additional Images of Sanatron Custom Engineered Systems

Explore a collection of images featuring our expertly crafted Standard and Custom Engineered Systems, each built with steadfast dedication to strength, precision, and peak efficiency. Whether your application calls for a pre-designed vacuum chamber or a fully tailored, concept-through-completion solution, our engineering expertise ensures impeccable alignment with your unique specifications. Connect with us today to leverage our extensive knowledge and create a solution meticulously refined to fulfill your exact requirements.

Product Specifications

Features

Description

The Stainless-Steel Vacuum Chamber engineered and locally manufactures by Sanatron for Pharmaceutical Processing Applications. The Quality Constructed stainless steel Vacuum Chamber is designed to meet the most rigorous standards of the pharmaceutical industry, ensuring reliable performance in critical applications where it absolutely matters. Its robust construction and advanced system capabilities make it ideal for maintaining contamination-free environments during testing and production.

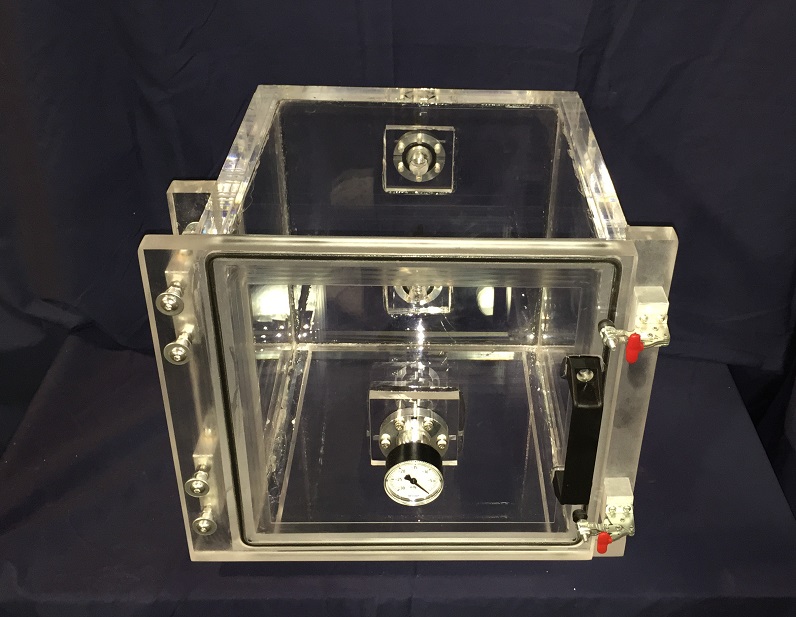

The stainless steel vacuum chamber has inside dimensions of 20 inch cube with a front loading clear acrylic door. The chamber has four additional and fully removable stainless steel shelves. The door hinges are specifically designed for vacuum application and adjustable for full compatibility and o-ring compression. Included with the chamber is a digital vacuum gauge capable of Torr and millitorr output. The vacuum valve is a KF25 size which is connected to a visi trap carbon activated inline filter and an Agilent Dry Scroll Vacuum Pump. There is a 0.25 inch NPT Vent Valve and a 0.25 inch NPT Plug for future expansion. The whole system is placed onto table frame structure with lockable swivel casters making this a fully portable vacuum system optimized for pharma applications.

This versatile system features four vacuum chamber shelves that allows for efficient organization and optimization of materials during operation. Paired with a dry scroll vacuum pump and chamber, the system ensures consistent and oil-free vacuum performance, minimizing maintenance requirements and enhancing overall reliability. Whether for drying, testing, or processing, this vacuum drying system delivers unparalleled efficiency and precision for pharmaceutical applications. If you have something in mind that is similar to what you are seeing but not quite like it, feel free to reach out and see what we can make for you.

You may be interested in some of our other items

Our clients prefer to work with us because we are Experts in Custom Fabrication (especially Polymer Fabrication). Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Additional Comments

1. Depiction: We go above and beyond to represent our products the best we can, but all images are for reference only. If you want the exact dimensions of a product, please refer to the product drawing. If the drawing is not present, please contact us.2. Discount: If you are ordering more than one item you will qualify for a discount, contact us for more details. No discount will be given after you have ordered and then realized you can get a discount. We put in a lot of effort writing this and we don`t reward failure to read our descriptions. However, since we are nice guys, we will give you a discount on your next order.

3. Shipping: The shipping rates are for the lower 48 states only; additional shipping charges apply to Alaska, Hawaii, and international orders. Keep in mind that international order will also be subject to duty and other charges.

4. Products: Our products are built-to-order; therefore, your product can be customized, but you must let us know beforehand. The pricing, shipping terms, and lead time apply to orders of less than three (3) items. If you are ordering more than 3 items, you should contact us to discuss your quote.

5. Return Policy: 14 days on all standard products. We stand 100% behind our products. If there was a mistake on our part, you will be refunded 100% of your money including shipping. If the mistake was on your part or you decided that you didn`t want it after all, you will pay for shipping and we will fully refund rest of your money. Chamber must be insured during return shipping for the price that you paid for and in a non-damaged condition. Return Policy does NOT apply to custom items, jobs, or products. If you have asked us to modify any of our standard products, you will not be able to return your item.