Degassing of Biotech Devices incorporating Custom Quality Products

A degassing system consists of a vacuum chamber, a vacuum pump, and vacuum pump connection hardware. Such system is used to remove entrapped gasses from a liquid. A biotech customer of ours contacted us to design, manufacture, and deliver a custom vacuum degassing system which included a custom tray, wire feedthroughs, and BNC Vacuum feedthroughs.

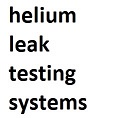

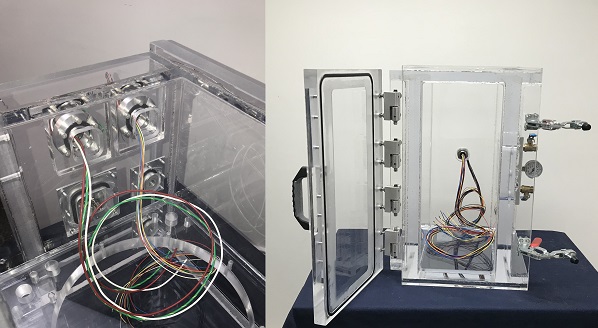

Due to being a cGMP facility, our customer had stringent requirements which had to follow strict FDA Guidelines. The degassing process had to be recorded, monitored, validated, and repeatable across batches. The system we provided for them was an acrylic vacuum chamber with 14 inch Inside dimensions. This was a fully assembled system – once they received this, all they had to do is plug it in, no additional assembly was necessary. The vacuum pump we provided to them was a piston pump. Although not ideal, since the maximum achievable vacuum is not as high as compared to the rotary vane vacuum pump, it was chosen due to the fact that a piston pump is an oil free pump and does not emit oil mist. Furthermore, an oil free pump will not have the risk of oil contamination thru product degassing. This was a table top chamber meaning only a vacuum pump and vacuum pump was provided.

The vacuum chamber customization included, a QTY: 3 x #14 Gauge wires, a QTY: 9 x #22 Gauge wires, QTY: 2 x BNC Coaxial Feedthrough, and a vacuum pump 0.25 inch NPT Feedthrough. Each feedthrough is fully vacuum sealed where they can be operated during full vacuum degassing operation without the loss of vacuum performance. A digital Vacuum gauge was also provided so that the degassing process can follow cGMP guidelines such as being recordable and reputable due to the fact that a digital vacuum gauge has a much higher accuracy and precision as compared to a dial vacuum gauge. If you are looking for a degassing system, please take a look at our vacuum degassing systems made by Sanatron. There are several standard systems available and we will be happy to customize these for you as per your requirements. Contact us for more information.

We have many more resources on our website that you should check out

We are an Engineering Excellence Company. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers