Product Quality Testing of Waste Management Components by utilizing Sanatron Chambers

One of the most important and thankless jobs are jobs in the waste management industry. This is one of the few industries that would be dearly missed if they disappeared. There is a reason why we have mostly clean water, clean air, and clean environment where we live. And that is because the people in the waste management industry do one hell of a job.

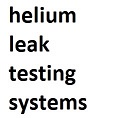

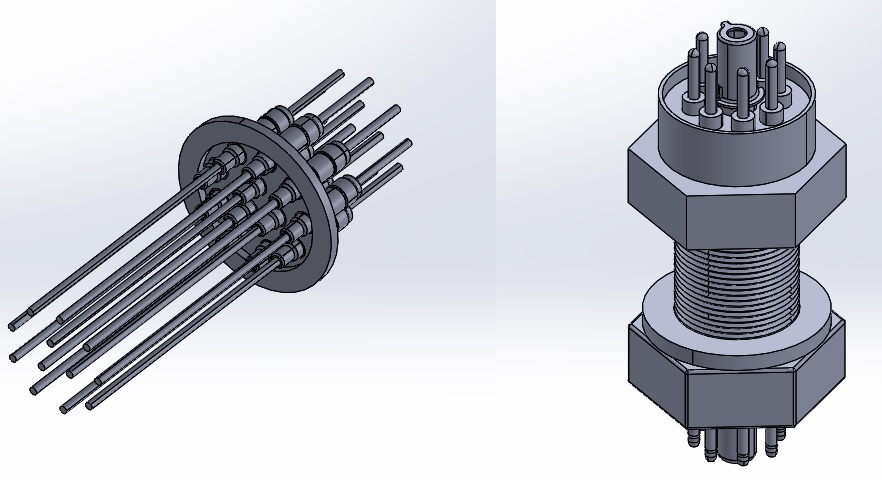

Our client, who is in the Waste Management Components industry contacted us to design and manufacture a total quantity of eight, acrylic pressure and vacuum chambers including a couple of feedthroughs on each wall. These chambers were to be used to product quality test the Waste Management components. The inside dimensions of these chambers are 14 inch Wide, 14 inch Deep, and 14 inch High. As a standard, each pressure and vacuum chamber comes with two 0.25 inch valves, one dial vacuum and pressure gauge, and one 15 psig safety pressure relief valve. Further customizations included a UBS port feedthrough and an SMA feedthrough and a wire feedthrough. A vacuum feedthrough is a component which allows you to connect and run, say USB from the outside of the chamber, to the inside of the chamber without loss of vacuum quality during operation. The lid also comes with a total of eight thumb clamps, these swing out of the way when the lid needs to be removed. Keep in mind that these clamps are not necessary required to be tightened during vacuum operation since the lid will provide sufficient weight to compress the O-Ring for air tightness. However, during pressurization operation, when the pressure is pushing the lid away from the chamber, these thumb clamps are vital as they compress the O-Ring and hold it in place to keep the pressure constant. A question that comes up frequently is: “What is the highest pressure a chamber made from acrylic can withstand?” The answer is 15 PSIG. Acrylic should not be frequently pressurized and operated beyond 15 psig. And that is what we here at Sanatron make – we do not design and build pressure chambers that are intended to be used for pressures beyond 15 psig. Is it possible to go beyond 15 psig? Yes, absolutely, we have seen acrylic be used in pressures at 500 psig. However, at these pressures, and above these pressures, the acrylic walls will be saturated with air molecules, these molecules will grow and bubbles will form. The formed bubble cavitations will expand and material defects will form which will degrade the acrylic resulting in uninvited consequences, if you know what we mean. Also, keep in mind that acrylic has been successfully used as a submarine material where it is subjected to 5000 psi of water pressure. So yes, it is possible to subject the acrylic to more that 15 psig, it is just something that is not a focus of ours currently.

Going back to our pressure and vacuum chambers, I am not sure what exactly our chambers have been used for. I am as curious as you are to find out. What we do know is that our client is extremely happy with the work we have done for them. These are not the only chambers we have made for them. Over the years, we have designed and built many more vacuum chambers, portable vacuum chamber and pump systems, and a pressure decay leak testing system (to test one of their pump valves). But this is a story for another time. If you are in the market for pressure and vacuum chambers, contact us to find out why we are the preferred chamber manufacturer.

You may be interested in some of our other items

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers