Vacuum Calibration of Automotive Parts incorporating Our Products

Have you heard people say that the newer cars produced today are actually computers on wheels? Well, don’t mean to scare you, it’s still a car, but it has a plethora of countless computer components and systems that are currently a part of every new car that comes of the production line. This is why, the last time we checked, a 2.4 liter naturally aspirated engine is able produce about 300 horsepower with an incredible fuel economy of about 25 mpg driving around the city.

If you haven’t been paying attention, cars have gotten quite more powerful over the past few decades without much increase in engine size. This is largely due to the better quality manufacturing technology. Every automotive part that is produced today has to be quality tested and properly calibrated. No longer is “good enough” really “good enough”. It has to meet the specs set forth by the car manufacturer to an incredible precision. Fortunately, automotive parts manufacturers and builders have Our Products to help them achieve their goals by producing the highest quality automotive parts they possibly can.

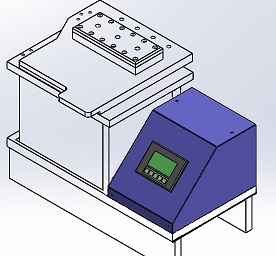

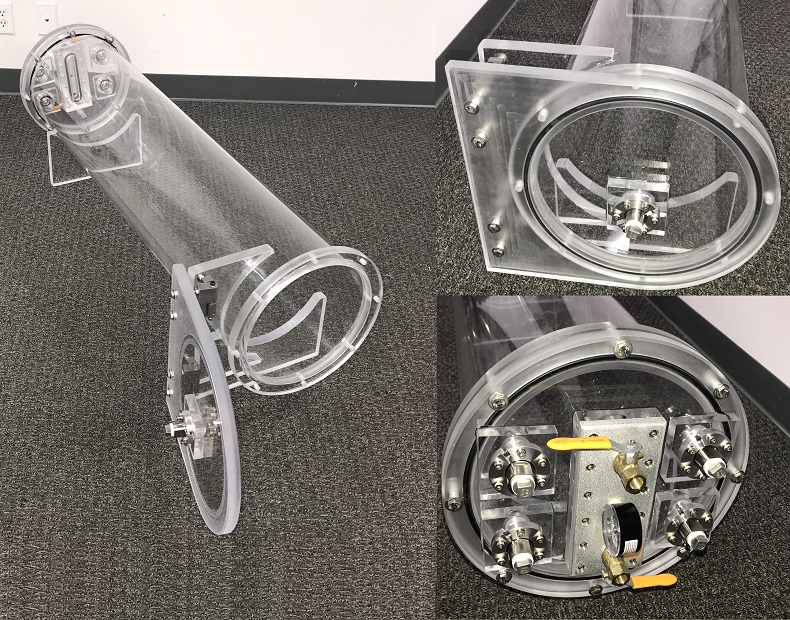

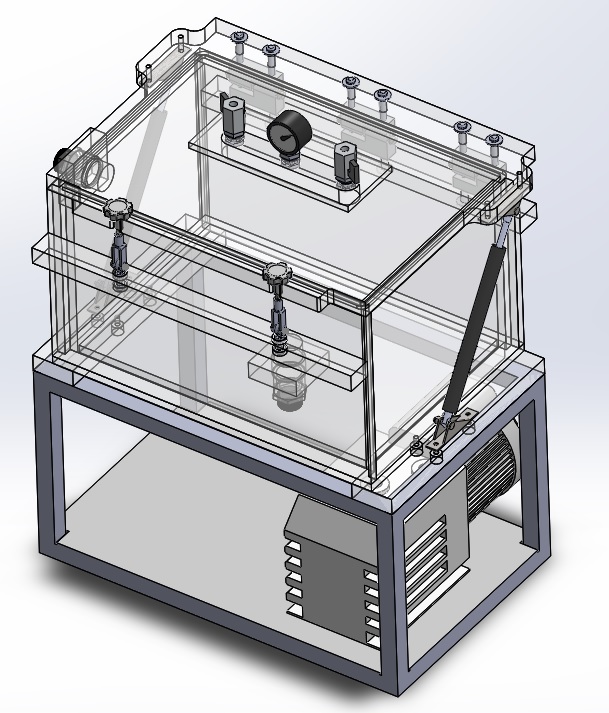

A large automotive parts manufacturer reached out to us to help them build a Vacuum Calibration Chamber so that they can test small to vary large sized automotive products they mass-produced. The system shown is a large acrylic vacuum chamber system with inside dimensions of 42 inch wide, 24 inch deep, and 12 inch high. This was a complete system which was placed on a custom built 80-20 Inc. table frame structure with lockable swivel casters. Their high thruput and output manufacturing operation requirements called for a fully automated vacuum calibration system. We therefore provided them with our Vacuum Controller which has the ability to reach their set vacuum level, hold it for a selected dwell time, and vent the chamber after dwell time has completed. The vacuum controller is connected to a digital vacuum gauge and two solenoid valves. One Solenoid valve is connected to the vacuum pump, the other is used for venting the chamber. By carefully monitoring the vacuum level inside the vacuum calibration chamber, the vacuum controller decides when to open each valve and when to run the vacuum pump. This system is fully assembled and quality tested and all our customer had to do is plug the vacuum pump and vacuum controller into their electrical outlet once they received our system and uncrated it. We make sure that there is no assembly nor additional work required by our customer when they receive our products – we want our customers to do what they are good at: make quality automotive parts. While at the same time, we want to do what we are really good at: making quality vacuum calibration systems. If you have a need for a vacuum calibration system, feel free to reach out to us. We always strive to be the experts in the field of vacuum technology and will be happy to look at your requirements to see if this is something that we can do for you.

Some of our Popular Items

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). Check out some of our other items we carry that you can combine/integrate with your systems or projects.

Complete List of Articles Related to Acrylic Vacuum Chambers