Aerospace Custom Vacuum Chamber

An aerospace company reached out to us because the needed someone to make a custom vacuum chamber for them. We are always happy to look at what we can do for them to make it happen. They did not tell us much about the details of their projects. This is sometimes the case because when work is done on proprietary technology, we do not expect to know every single detail.

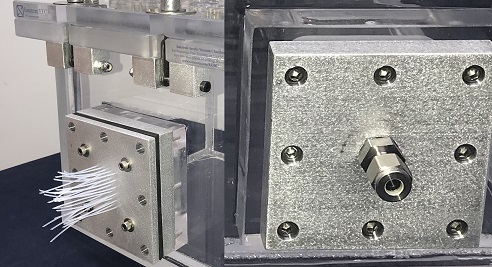

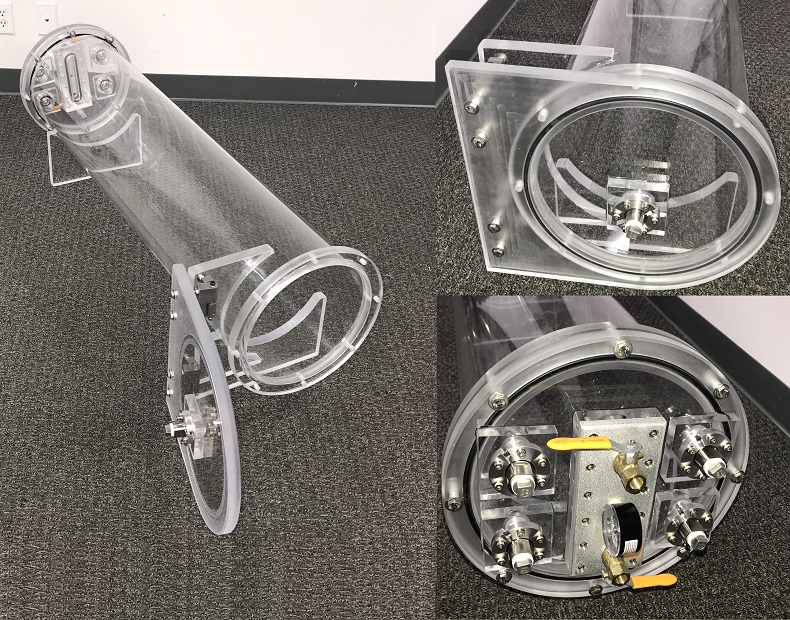

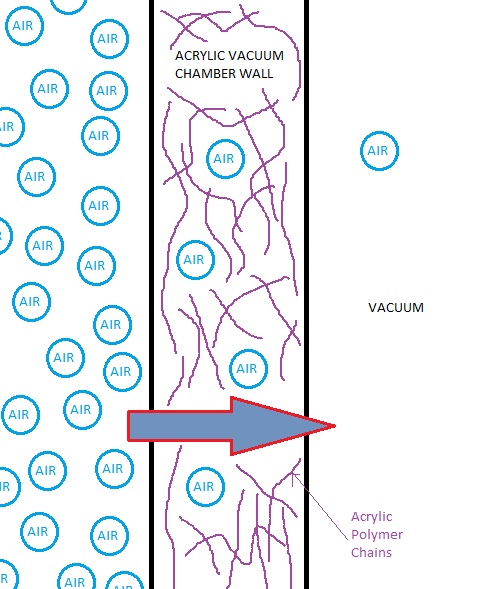

They had a need for a vacuum chamber with inside dimensions of 42 inch Wide, 42 inch inch Deep, by 12 inch High. Furthermore, the vacuum chamber would need to have O-Rings on both sides of the large 42x42 wall openings. What we came up with was on O-Ring groove present inside the flange. Our O-Ring groove is precision routed and dove tailed. The Dovetail will hold the O-Ring in place even if it is flipped upside down. This is not something our competitors do which is why their O-Ring will fall out if the lid is either turned outside down or if the lid is shaken; sometimes the O-Ring will pop out randomly. This is why it is vital to have the dovetail O-Ring Groove. Another critical feature is precision routing. When routing an O-Ring used for vacuum applications, router bit, feed, speed, cooling, and vibration are of utmost importance. We have spent more than 14 years perfecting our process which is why our acrylic vacuum chambers yield superior vacuum performance rivaling our competitors chambers made from stainless steel. Our acrylic is stronger than their steel!

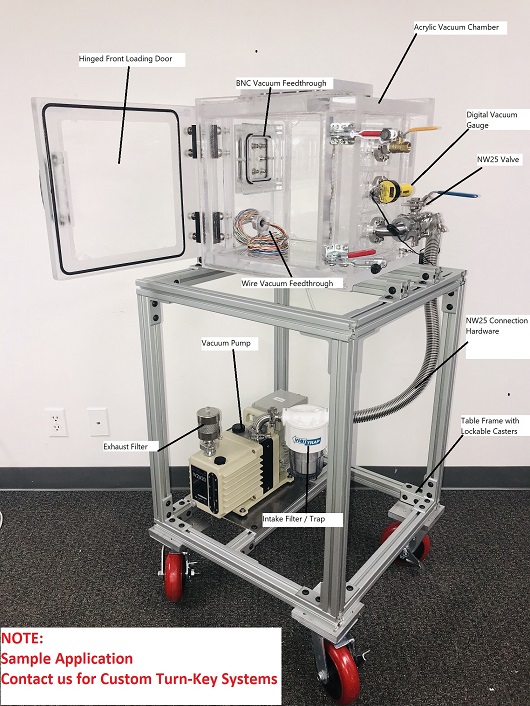

The Sidewalls are 12 inch High and were made from 2-inch Thick Acrylic. If you look to the Left of the chamber, you will notice a vacuum gauge and two valves. You will also notice that the top and bottom walls are flanged and slotted which will allow our customer to easily attach their top and bottom wall to our custom-made chamber. Do you need to make a custom vacuum chamber? Are you looking for great quality and robustness? Reach out to us to see what we can do for you.

Did you know that we carry a many more products?

We are an Engineering Excellence Company. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers