Electronic Integrity Testing inside Custom Pressure and Vacuum Chamber

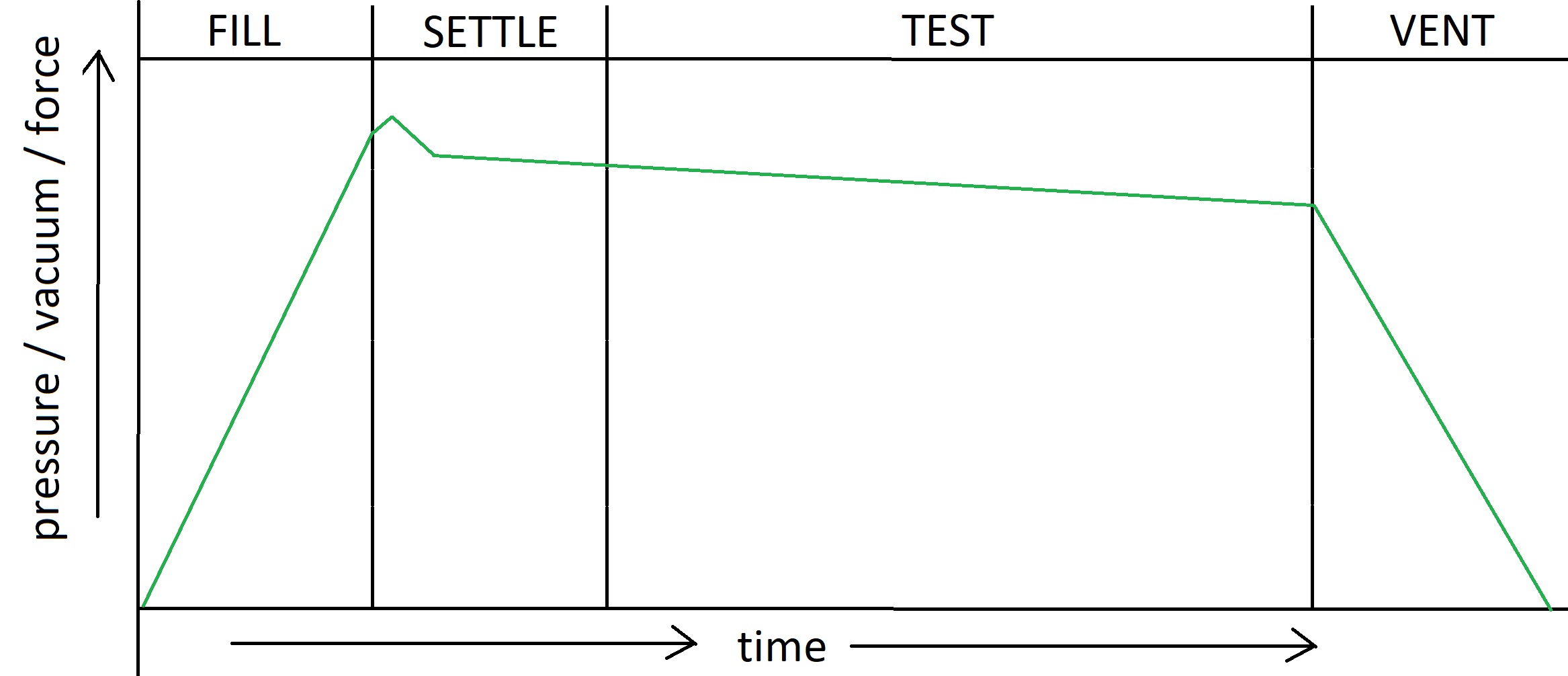

One of our customers who designs and builds Electronic and Electrical Equipment reached out to us because they had a need for a custom acrylic pressure and vacuum chamber. They needed to subject their electrical components to a vacuum or pressure environments in order to test the performance of their electrical equipment.

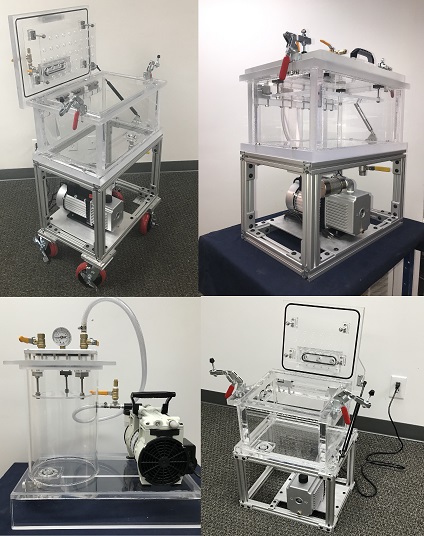

What you are seeing is an acrylic pressure and vacuum chamber. We are looking at the chamber from the right wall. The right wall has a USB vacuum feedthrough and an 8 pin, 5 amp, power feedthrough. The rear wall has an electronic board installed towards the top. The left wall has QTY: 2 x Swagelok Type tube feedthrough, so-called liquid and gas feedthroughs, for a 0.25 inch OD tube. This is intended to be used to run coolant into the chamber during vacuum and pressure operations without compromising the vacuum or pressure operations. The reason there are two liquid and gas feedthroughs is because one tube is used to run the coolant into the chamber while the other is used to run the coolant out of the chamber.

The chamber dimensions are 12 inch Wide, 12 inch Deep, and 18 inch High. There are a total of QTY: 8 Thumb screws which are used to bolt the lid down during pressurization. The lid contains two valves, one dual pressure and vacuum gauge and one safety pressure relief valve that will pop open at 15 psig (the maximum allowable pressure for such chamber. The lid also has two lid handles. You will notice that the bottom wall has interesting design where there are a total of QTY: 8 x slots, 2 on each side. These are used to fasten this whole assembly onto a work table. Are you looking for a pressure or vacuum chamber? Do you need to customize it? Does it need to be robustly designed and quality manufactured to consistently perform and meet your needs? Contact us!

Did you know that we carry a many more products?

We are an Engineering Excellence Company. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers