Vacuum Soil Sampling and Extraction for Geological Research

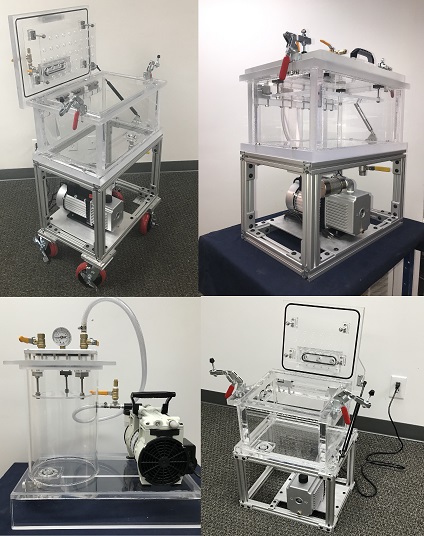

What you see here are two identical vacuum chambers with a spring supported lid which are used in vacuum soil testing and extraction methods. Our client asked us to provide them with two vacuum chambers capable of reaching vacuums below 1 Torr absolute.

Since the test specimen preparation time is much shorter than the vacuum sampling time, it makes much more sense from an efficiency standpoint to use two vacuum chambers. In addition, the test is done in two stages using one chamber as a staging chamber and the other one as the sampling and extraction chamber.

A spring support lid chamber is the ideal choice for such applications. The lid stays open as the samples are loaded into the chamber. Then, after the chamber is loaded with the test specimen, the lid is closed and clamped and vacuum can be applied to the chamber. This chamber also comes as a standard with a vacuum valve, a venting valve, and vacuum gauge, a handle, two clamps, and two spring to support the lid.

WAIT! Take a look at similar Items you may like…

We make Robustly Designed and Quality Engineered Systems. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers