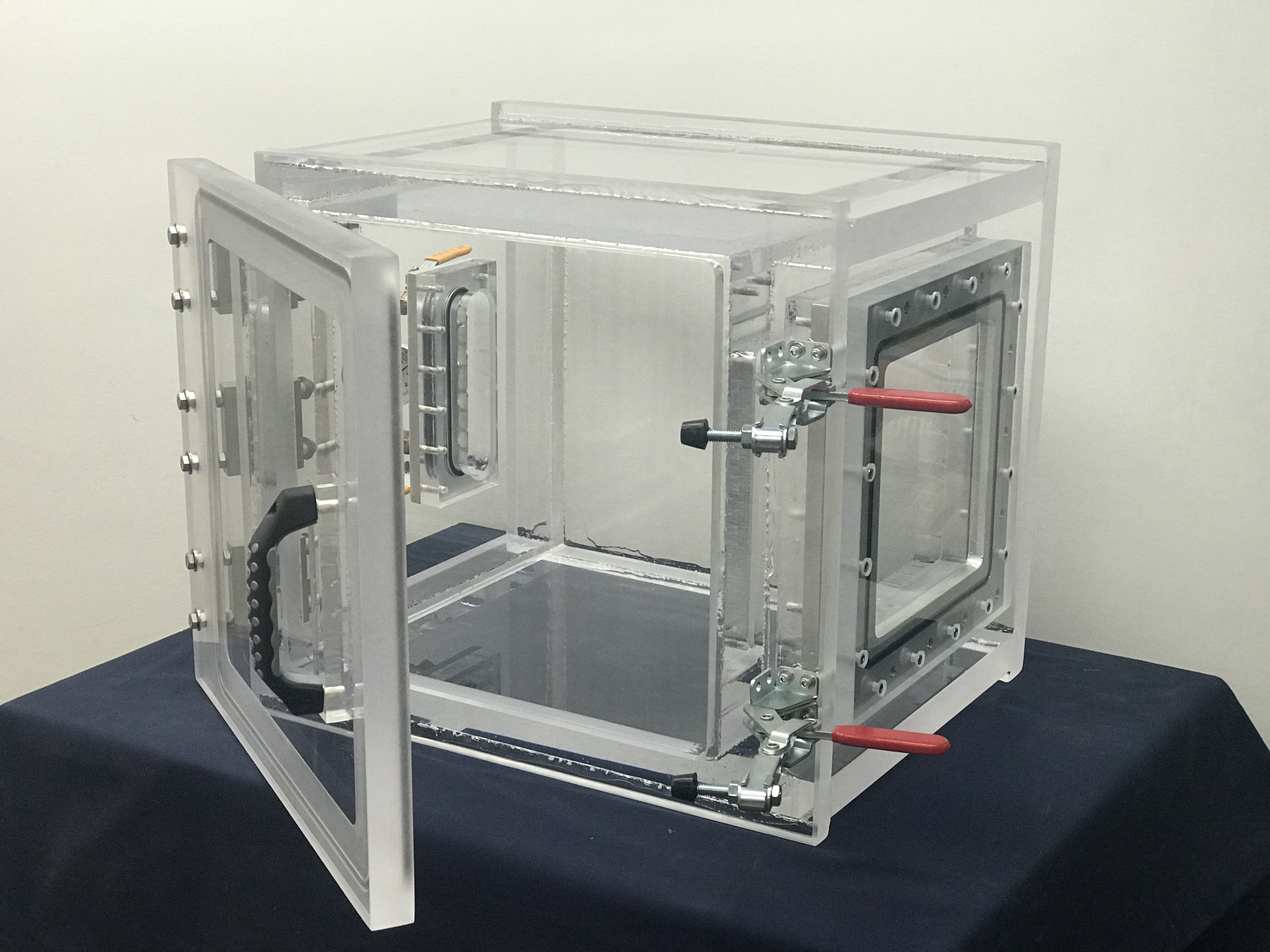

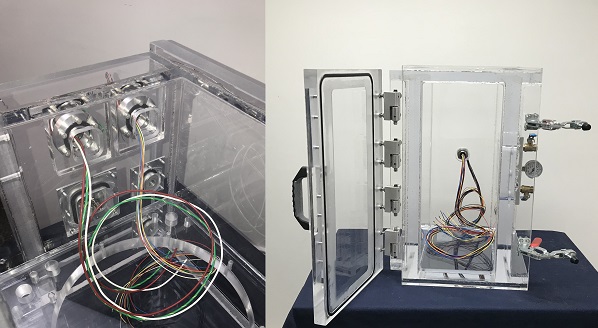

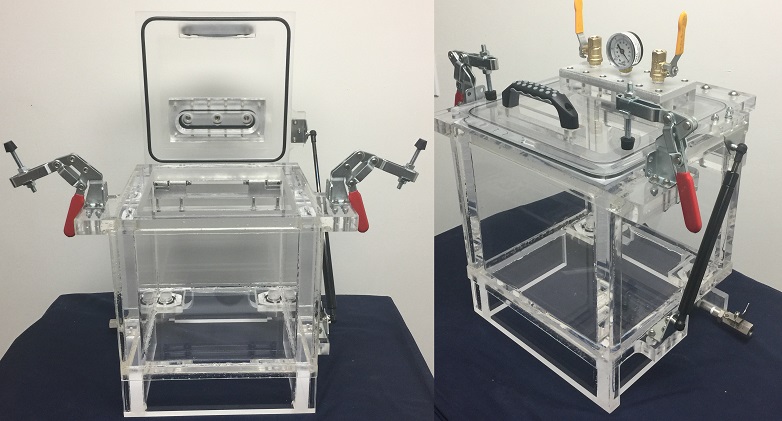

You are looking at our standard Acrylic Vacuum Chamber, Hinged Door with Clamps. There is only one difference; this vacuum chamber has a blank acrylic plate that is connected to and aluminum plate which in turn is anchored to the side wall of the acrylic vacuum chamber. This blank plate is there to enable our client to add vacuum feedthroughs to the side wall in the future. During the fabrication phase, our client did not know what vacuum feedthroughs they would need in the future. We decided that it was best to simply add a blank acrylic plate which can be removed, customized, and fastened back to the acrylic vacuum chamber. Additionally, our client would have the option to envision, design, and fabricated their own additional custom vacuum plates should that need arise in the near future.

Now to the Aluminum Part, why is there an aluminum plate anchored to the acrylic side wall? Well, the aluminum plate is there to increase the service life of the threads. We do not like to thread into the acrylic walls of our vacuum chamber, what we do instead is we press threaded inserts into pre-drilled holes. When a bolt is being fastened into the threaded insert, the insert will slightly expand and grab onto the hole wall; hence anchor. The threaded insert creates a compression force on the acrylic walls instead of a shear force had we threaded the hole instead. Acrylic is able to handle compressive forces of the insert a lot better, it does not does not do too well during shearing forces. If the shear force is too high, the walls will begin to craze.

So, there you have it, this is why we have the aluminum plate there. Our customer will fasten the blank plate to the aluminum instead of threading into the acrylic.

If you would like to find out more about how to get a similar vacuum chamber, fell free to Contact Us

Similar Items

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers