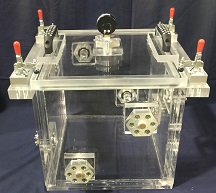

An acrylic vacuum and pressure chamber can also be used for water resistance testing as well. If you fill up your vacuum chamber with water and then submerge a testing device into water. If you then pressurize this chamber by applying up to 15psi of pressure, you have now simulated a water depth of 33 feet, or 10 meters, or 1 ATM. Congratulations, you have enabled yourself a wide array of water resistance testing procedures such as the IP65, IP67, IPx7, IPx8, and 1 ATM. How about some bubble emission testing? Yes, it can do that too.

With this client, we cannot go into much detail on what exactly they were doing with this system. However, what we can do is to show off our engineering nerdiness.

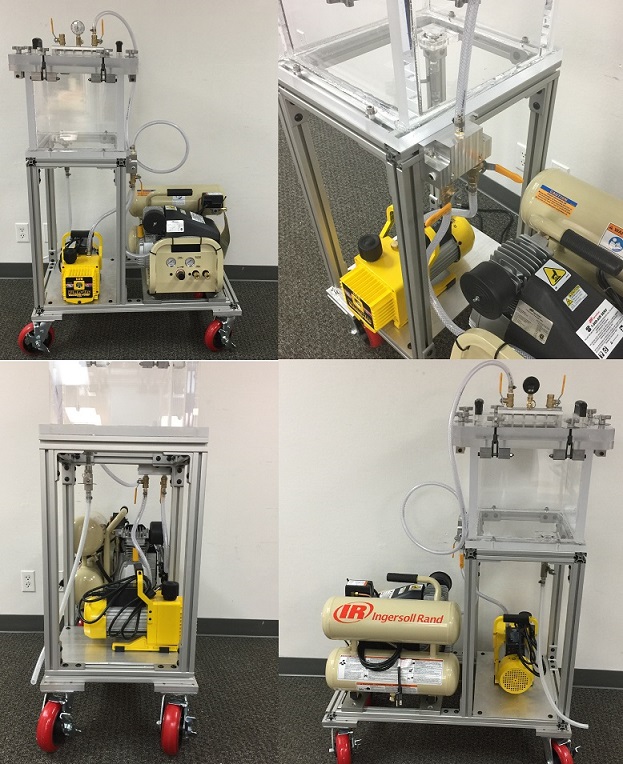

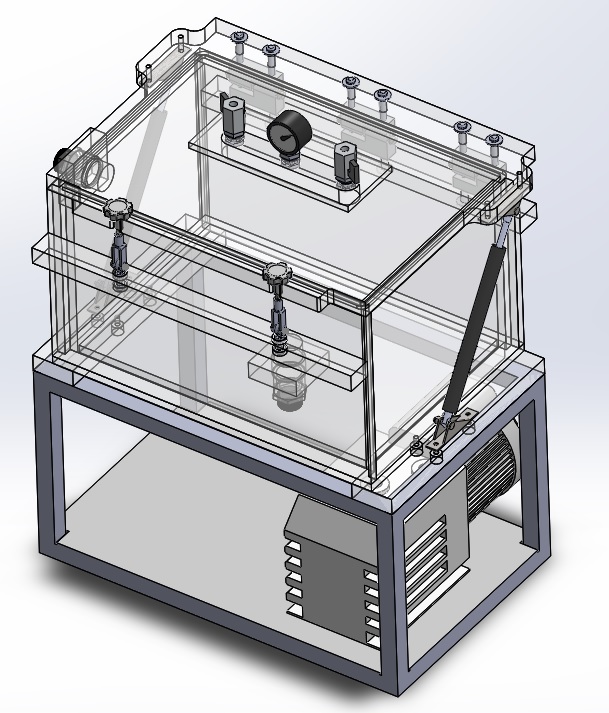

What you are looking at is a portable acrylic vacuum and pressure chamber. This is a complete Turn-Key system capable to be deployed anywhere as long as you can connect it to a power cord. This system will enable three kinds of tests such as the vacuum dry test, the bubble leak test, and the simulated water depth test. This chamber can go from 200,000 feet air altitude to a depth of 33 feet of water.

Below the vacuum chamber is a vacuum pump. Right next to the vacuum pump is a compressor. Both are connected to a manual manifold which can be toggled to enable the vacuum chamber to be either evacuated or pressurized depending on the type of test the user wants to perform. All assembly components are bolted down to the frame structure into place. You can also see that this Turn-Key System has lockable swivel casters.

The lid is clamped down by thumb screws during the pressurization phase to keep the Lid compressed against the O-Ring. It is not necessary to compress the lid during evacuation phase since the weight of the lid already provides sufficient sealing to initiate the vacuum. Of course, with every pressurized system, we add a pressure relief valve which pops open if the pressure reaches 15 psig.

Before I forget, this system has a drain valve of course. If you think about it, how else would you drain that chamber? You would be forced to tilt it or scoop the water out. The drain valve is connected to a drain hose which runs down past the vacuum pump. This was something our client suggested, it was a smart and obvious idea because this way, the risk of splashing water onto the vacuum pump during the drain process is eliminated – the water now exits not at the valve but at the end of the hose where the operator can simply place a bucket and drain the tank.

Are you performing a wide range of tests which could utilize a vacuum chamber? Do you need a custom vacuum system? Let us help you make a difference, Contact Us.

WAIT! Take a look at similar Items you may like…

We treat our customers well by Over-Delivering on our Promises (reason why we are Highly Rated on Google My Business). There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers