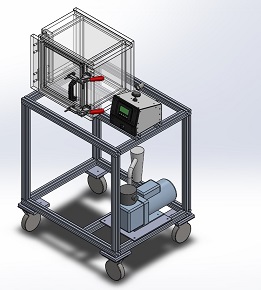

Custom Vacuum System consisting of Multiple Interconnected Vacuum Chambers

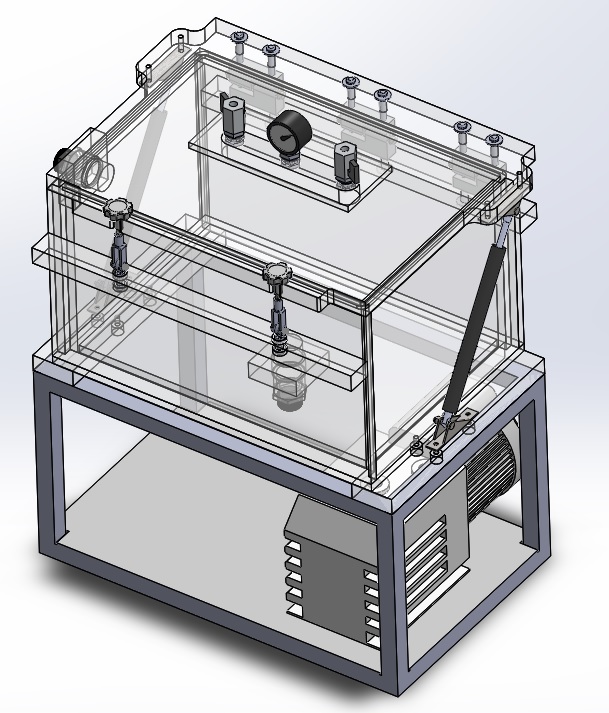

You are looking at a QTY: 2 x Acrylic Vacuum Chambers with inside dimensions of 20 inch Wide, 20 inch Deep, and 20-inch High. Both chambers are connected via a Cylindrical Acrylic Vacuum Chamber, the cylinder is 12 inch Deep and 24-inch High. The cylinder has a 320 ISO port connection on both sides. Making this a complete Multi-Chamber Vacuum System consisting of a total of 3 (three) interconnected and vacuum leak tight chambers.

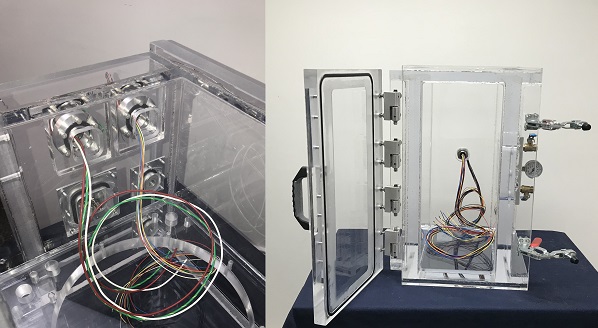

The two square vacuum chambers are slightly different when it comes to its arrangement of custom ports. The chamber on the left has a total of QTY: 4 x 275 ConFlat Bulkhead Ports, a QTY: 2 x 450 ConFlat Bulkhead Ports, and one 800 Conflat Bulkhead Port. Each Bulkhead port is blaked off with it’s respective blank; square O-Ring included. The Chamber on the right has a total of QTY: 5 x 275 ConFlat Bulkhead Port and a QTY: 2 x 450 ConFlat Bulkhead Ports. Both Chamber have an Optical Breadboard that is 18 inch Wide by 18 inch Deep anchored to the bottom Wall. Both Chambers also have four lid clamps, two 1/4 inch NPT Valves, One Dial Vacuum Gauge, and Two Lid Handles. The lids are fully removable and so are the ConFlat Blanks on each port present on the sidewall.

If you would like to check out our other work and the cool stuff that we make, check out our work: If you are looking to make a custom vacuum system consisting of Multiple Interconnected Vacuum Chambers, contact us.

You may be interested in some of our other items

We are an Engineering Excellence Company. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers