Force decay Testing of Medical Devices using Custom Vacuum Chambers

Medical Devices are subject to much regulatory scrutiny and compliance and therefore must perform as intended and as specified. Furthermore, device or product failure is not an option when it comes to medical devices. This is why performance and product quality are of utmost importance.

A medical device manufacturer, and we are talking about the largest medical device manufacturer in the work, reached out to us looking for a non-destructive leak testing solution to their surgical balloons. These balloon type of catheters are devices which are inserted into the veins or arteries of a patient and ran towards a target location. Once this balloon type device reaches it’s destination, the balloon is inflated causing an expansion of whatever needs to be expanded on that location. Sometimes it is a mesh which is inserted and expanded into arteries in order to open up a clogged artery and improve blook flow. Other times, it is something else. As you can see, it is critical that the balloon does not leak, because a leaking balloon will put the patient at risk as air will be filling the vanes of the patient and therefore putting them at great risk. Some approaches have mitigated the risk of balloon failure by inflating the balloon with saline solution which would not put the patient at risk if balloon failure occurs. However, there is still of risk of debris being deposited and left in patient vanes.

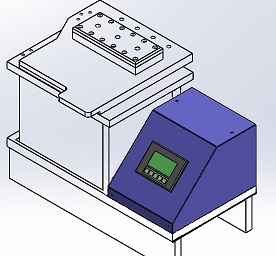

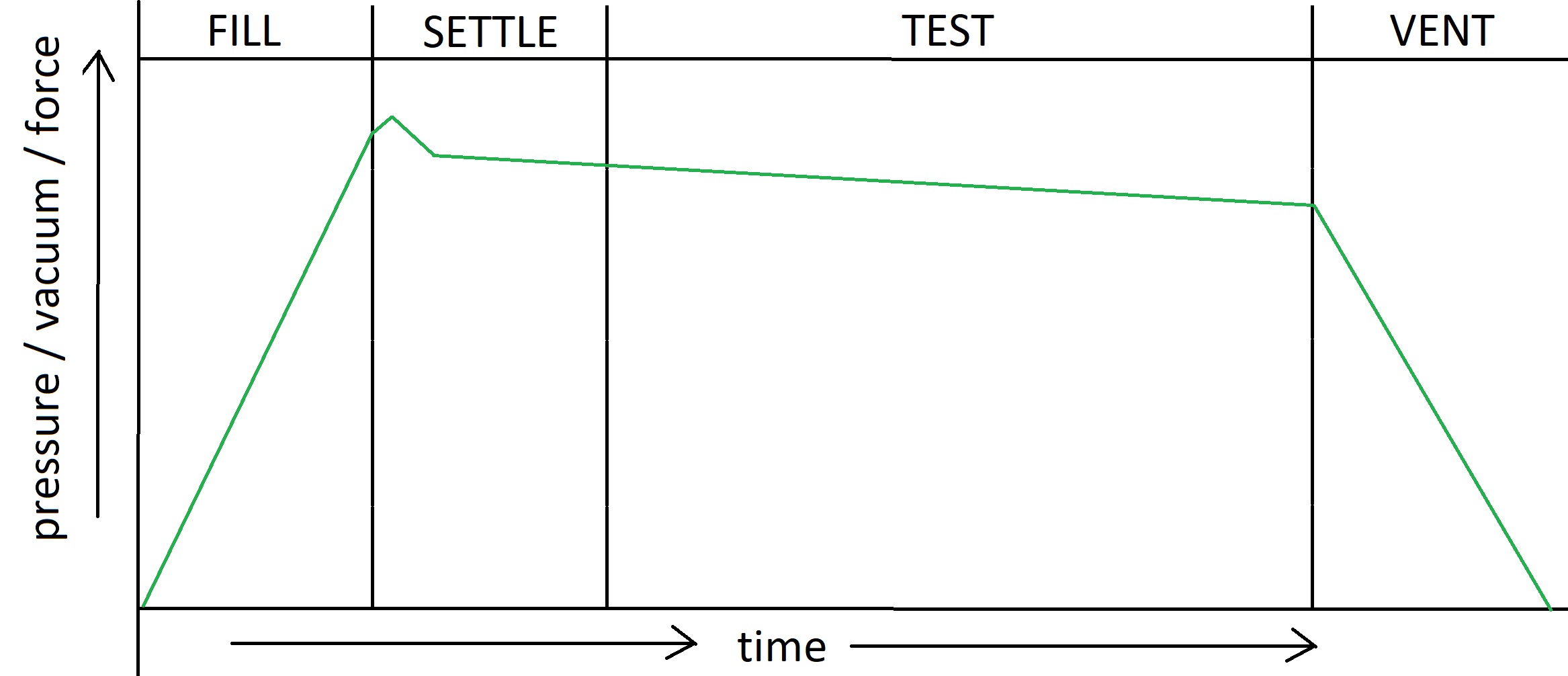

We design a custom vacuum chamber to accommodate various sized balloon our client was making. We also ran a vacuum feedthrough into the chamber which was connected to the force transducer present at the balloon testing site. When a vacuum is pulled, the balloon will inflate and apply force to the pressure transducer. This force will be measured and a leak rate will be calculated based on the decay in force over specified testing time. A larger vacuum chamber enables multiple testing specimen to be tested simultaneously eliminating the risk of production delays. The force decay leak test was only one of the many tests this medical device was subjected to during it fabrication process. We do talk about our other leak testing methods in other articles. If you are looking for a force decay leak tester that will help you produce medical devices with the highest degree of performance and quality, please check out our leak testing systems to explore ways how our products can help you.

Some of our Popular Items

Our clients prefer to work with us because we are Experts in Vacuum Science and Technology. There is a tremendous amount of valuable resources and information regarding vacuum systems and vacuum technology; check them out by clicking on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers