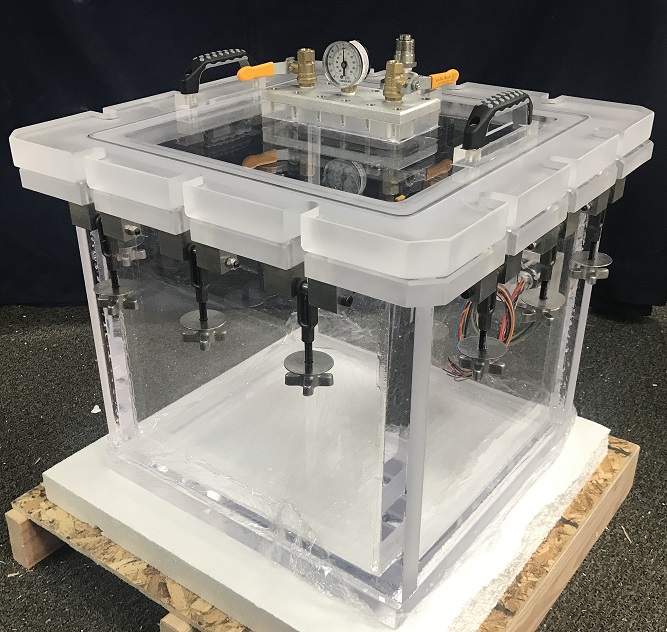

Portable Pressure Chamber and Custom Vacuum Chamber System

This portable pressure and vacuum chamber system is specifically designed and built to operate between an absolute pressure range of 60 kPa to 120 kPa. The pump is both a compressor and a vacuum pump. The maximum achievable vacuum of this pump is -25.5 inHg while the maximum achievable pressure is +15 psi or 30inHg. Keep in mind that if a more powerfully vacuum pump is used, a much higher vacuum is achievable because the acrylic pressure and vacuum chamber is capable of going into as low of a vacuum as the vacuum pump allows. On the over-pressurization side of things, the highest pressure this chamber is rated at is 15 psig (g for gauge pressure). This 15psig overpressure allows for water intrusion testing by simulating 10 meters of water depth when the chamber is filled with water and pressurized to 15 psig.

This is a complete system that includes the pressure and vacuum chamber, a vacuum and pressure pump, connection hardware, table frame structure with lockable swivel casters – making this a fully portable unit. There is one additional customization to this chamber and that is that it has an electrical outlet feedthrough on the left wall.

As a standard, each one of our vacuum and pressure chambers comes with two 1/4 inch NPT valves, a dial vacuum and pressure gauge, two lid handles, and a 15 psig safety pressure relief valve which will pop open if the pressure inside the chamber ever exceeds 15 psig. The inside dimensions of this chamber are 20 inch Wide, 20 inch Deep, and 20 inch High. Furthermore, there is a pneumatic toggle valve which allows the user a simple toggle between pressure and vacuum. When the level is toggled towards the front, the chamber is pressurized. On the other hand, when the lever is toggled towards the back, the chamber is subjected to vacuum. The toggle is of course labelled with “Vacuum” and “Pressure” and arrows pointing toward each direction. The lid comes with a total of 16 Thumb clamps, which swing out during openings, and are used to hold the lid down, and keep the O-Ring compressed during pressure operations. Yes, these are not required to be engaged during vacuum operations because the vacuum itself will pull the lid and compress the o-ring by default.

Did you know that we carry a many more products?

We are an Engineering Excellence Company. What are you building? Take a look at the links below and discover some of the cool things we make.

Complete List of Articles Related to Acrylic Vacuum Chambers