Quality Assurance of Medical Devices by utilizing Vacuum Chamber and Pump

A vacuum chamber and pump are used in various applications. A vacuum chamber is used to quality test product integrity and specifications. For example, subjecting product to vacuum can help determine the robustness of the product. It can also help determine how this product will behave at lower pressure.

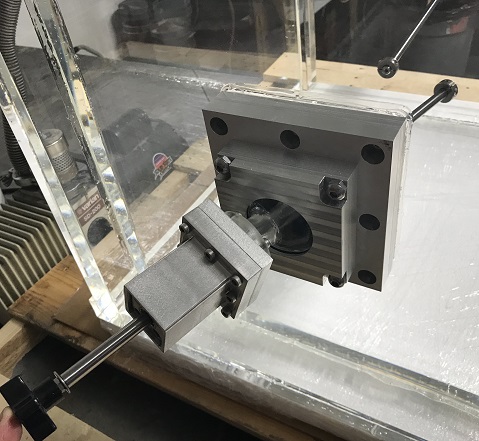

A biotech company reached out to use because they needed a vacuum chamber and system to perform Quality Assurance testing on a variety of their products. They needed something simple and easy to use which is easily operated by everyone in their Quality Assurance Lab. They also needed something that can be placed onto their Lab Bench Top without taking too much space. What you see is a 12-inch front loading, Acrylic Vacuum Chamber. The vacuum chamber opens toward the front, like a fridge, where it can be loaded and unloaded after fully opening the door. As a standard, this chamber comes with two valves and a dial vacuum gauge. One valve is used for vacuum, the other valve is used to vent the chamber and release the vacuum, the dial vacuum gauge will indicate the vacuum levels of the chamber. Included with the chamber is an oil free piston pump from Welch with the ability to pull of vacuum of about 10 Torr. This is more than they need for their test, but it is nice to have because you never know what testing requirements they might have in the future. The vacuum chamber and vacuum pump are connected and optimized for best vacuum performance. The vacuum pump is placed on top of the vacuum chamber in order to save space.

One of the advantages with having us make a vacuum chamber and pump system for is that we provide a fully assembled, ready-to-go, turn-key solution. There is no work required on your end. After you uncrate you vacuum chamber and pump system, all you have to do is plug the vacuum pump into the electrical socket and you are ready to go to start you work. When you work with us, we do all the work for you and there is no work required on your end. No need having to look into long complex vacuum valve specification tables in order to find the vacuum valve that may work for you – we have already done that. No need to look for a vacuum pump and having to scour the web emailing and calling various loosely trained customer facing reps who in the end will send you the wrong part and you will be stuck having to explain to your boss why your project is late. We got the perfect pump specified, connected, tested, and ready to ship to you so that you can do the work you are good at and need to do; we have done the work we are good at, and provided you with a complete system. We are looking forward to hearing from you and finding out how we have help you with your vacuum chamber in pump needs.

Similar Items

We are an Engineering Excellence Company. You should check out some of our other items we carry; click on the links below.

Complete List of Articles Related to Acrylic Vacuum Chambers